Multi-component rod for hot spraying wearable sealing coating and preparation method thereof

A sealing coating, thermal spraying technology, applied in coating, metal material coating process, fusion spraying and other directions, can solve the problem of difficult powder with uniform composition, suitable particle size range, different melting degree of powder, and inability to guarantee bonding strength. and other problems, to achieve the effect of easy control of the production process, short production process flow and moderate coating hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

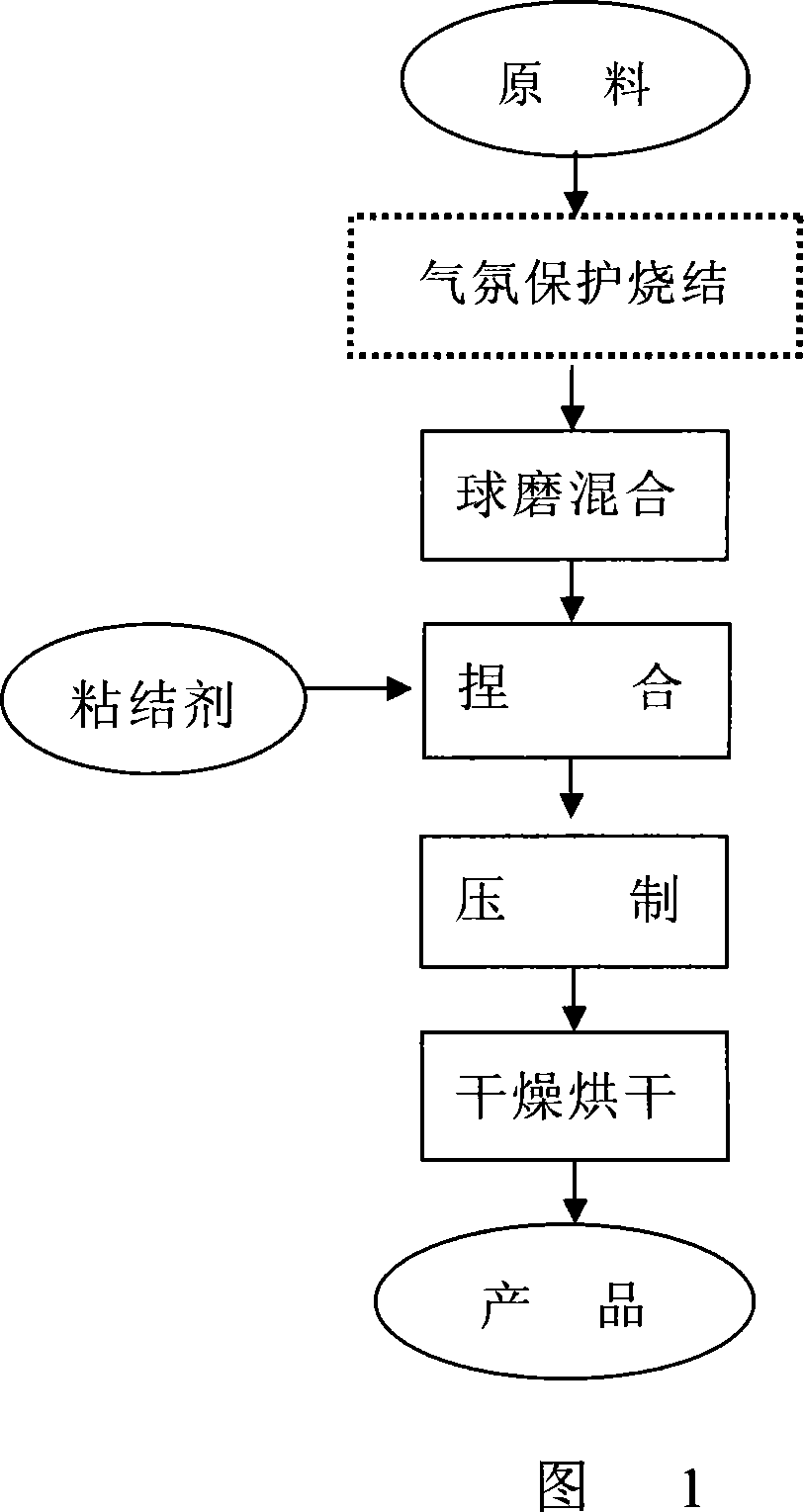

[0021] Use Al, C elemental powder, Ni, Si alloy or elemental powder, Si oxide or other salts as raw materials, and BN in a certain proportion, among which C, 3.0%; Al, 3.0%; Si, 8.0%; BN , 8.0%; the rest is Ni. The above-mentioned various raw materials are mixed by mechanical ball milling, and aluminum dihydrogen phosphate is added after they are uniform, and water can also be added for mixing (or ball milling and mixing at the same time). The binder ratio is 25.0% of the powder, and the ratios are weight ratios. . It is pressed (25MPa) on a hydraulic press, placed in a tray after forming, and the temperature rise rate is automatically controlled by a program temperature controller. When the temperature is raised to 100-200°C and kept at a constant temperature for a period of time (3 hours), the components in the binder will volatilize and the rod will be densified. Accompanying drawing 1 is the flow chart of processing process.

[0022] The same effect can also be achieved...

Embodiment 2

[0025] Use Ni, Cu elemental powder or alloy, C elemental powder Si oxide or other salts, and BN as raw materials, and mix them by mechanical ball milling according to a certain proportion, of which C, 8.0%; Cu, 20%; BN, 7.0%; Si, 4.5% %, the rest is Ni. After mixing evenly, add a silicate aqueous solution as a binder, press on a hydraulic press, and dry after forming. Get rods.

[0026] The same effect can also be achieved if phosphate or organic matter is used instead of silicate as the binder.

[0027]Flame spraying sealing coating, under certain spraying parameters, superalloy as the base material, experiments show that the hardness of the coating is 8-14HB, no cracks occur on the coating surface, and it has good wearability and salt resistance Fog corrosion performance, high tensile strength. The hardness of the coating after heat treatment at 200°C for 100 hours is not greater than 11.0HB, and it can be used as a sealing coating under this temperature condition.

Embodiment 3

[0029] Using Ni, C, BN, Si oxide or salt, CuO, CdO as raw materials, according to a certain ratio of mechanical ball milling, uniformly adding binder polyvinylpyrrolidone (PVA) ethanol solution, hydraulic press, drying after forming to prepare hot Rods for spraying sealing coating.

[0030] If the polyvinylpyrrolidone ethanol solution is replaced with an inorganic binder or other organic matter as a binder, the same effect can be achieved.

[0031] The sealing coating is prepared by flame spraying. Under certain spraying parameters, the hardness of the coating is 5 / 62.5 / 30. No significant changes. This material can be used as a sealing coating at 700°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com