Method for synthesizing organic-inorganic composite silicon oxide nano-line

A composite silicon oxide and synthesis method technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of product purity decline, cumbersome reaction steps, incomplete reaction, etc., and achieve the effect of simple steps, large output, and high insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

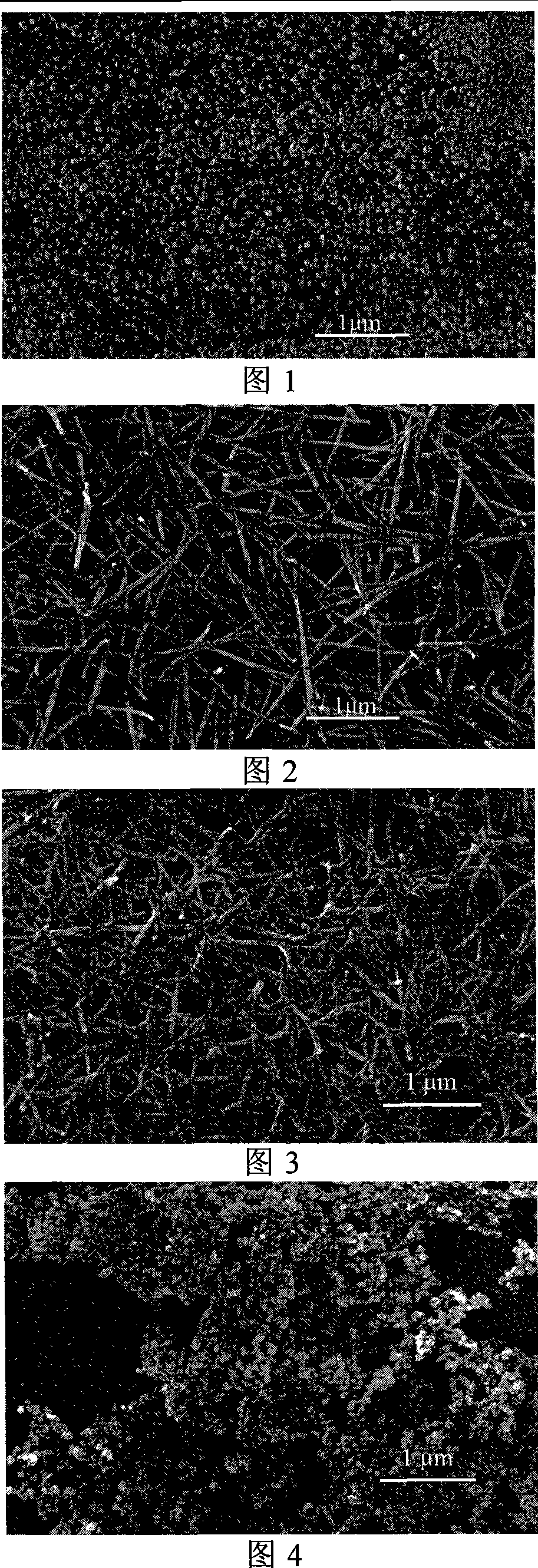

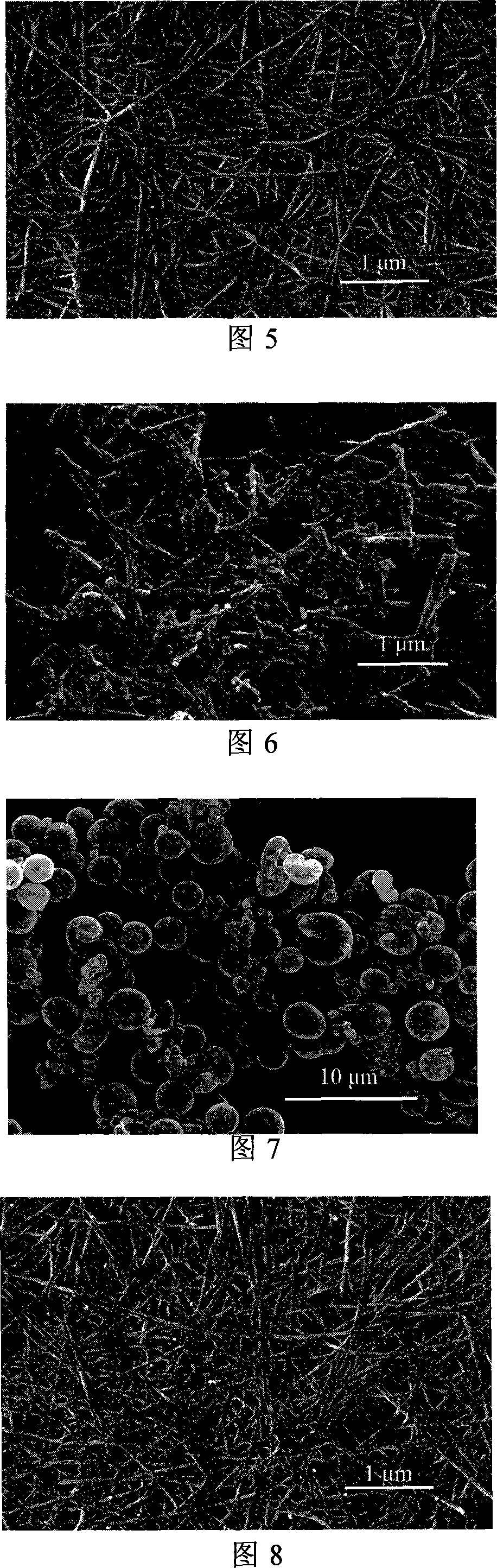

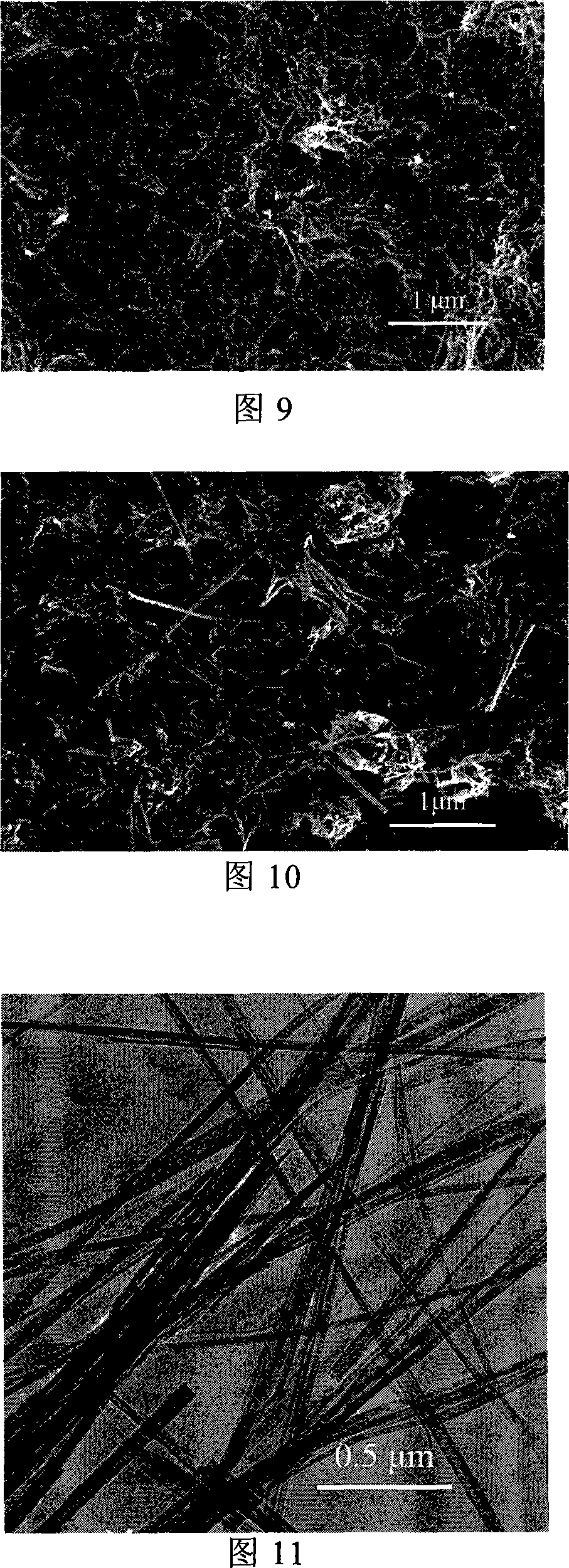

example 1

[0042] With 3.75g silica sol (silicon oxide content is 40%) A 1 Disperse in 25ml of 0.5mol / l ferric chloride solution and oscillate. After the system is evenly mixed, add 40ml of ethylenediamine solution, oscillate, and sonicate for 15 minutes. Transfer the well-mixed mixture into a reaction kettle with a polytetrafluoroethylene liner, tighten the reaction kettle and place it in an oven at 200°C for 5 days of reaction; take out the reacted green solid with water and ethanol respectively After washing 5 times, a silicon oxide nanowire A with an organic-inorganic composite structure will be obtained 2 . The silicon oxide nanowires with an organic-inorganic composite structure were stirred with 1 mol / l hydrochloric acid solution for 1 hour at a temperature of 80°C; finally, the solids treated with hydrochloric acid were washed with water three times, and dried at room temperature to obtain a white powder Solid pure inorganic silica nanowires A 3 .

example 2

[0044] Experiment with the same method as example 1, but with 3.75g silica sol A 1 Replaced with 1.50g white carbon black B 1 , the product B can be obtained 2 (before pickling) B 3 (after pickling).

example 3

[0046] Experiment with the same method as example 1, but with 3.75g silica sol A 1 Replaced with 1.50g HMS silica pellets C 1 Available product C 2 (before pickling) C 3 (after pickling).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com