Method for extracting polysialic acid

A technology for polysialic acid and purpose, applied in the field of extracting polysialic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

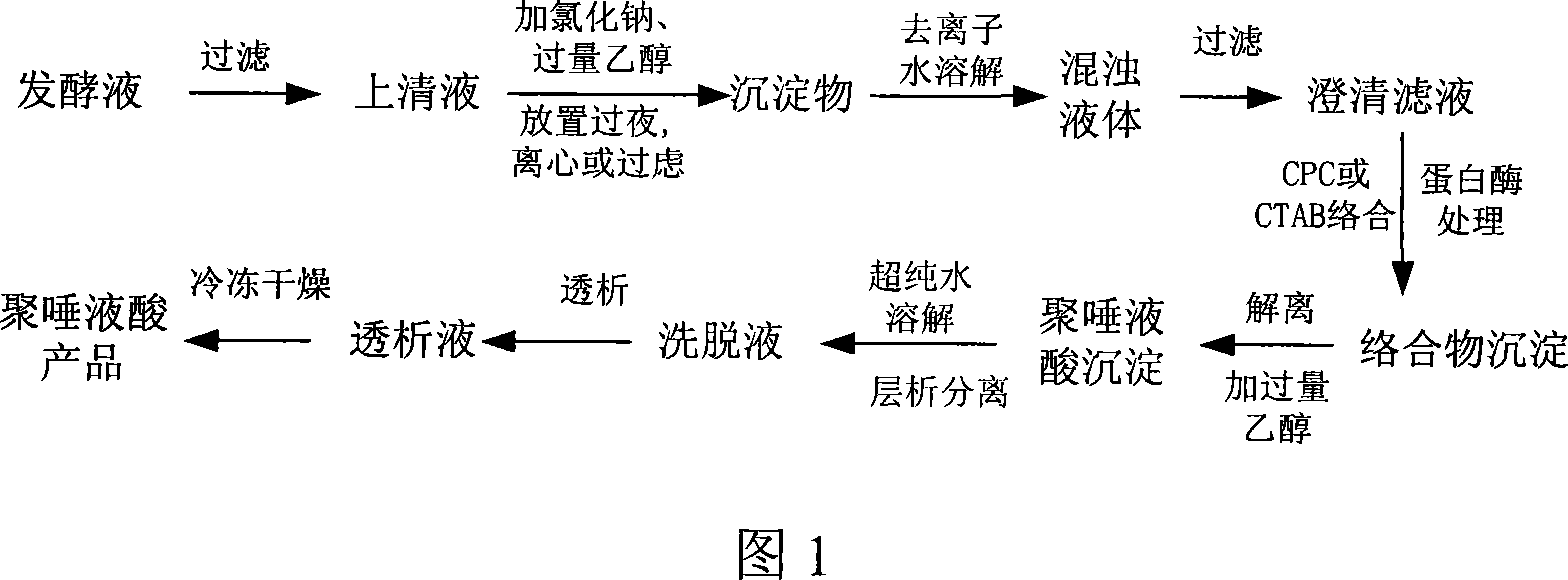

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. Preparation of polysialic acid fermentation broth

[0025] Strain Escherichia coli K235-JY II-74.

[0026] Fermentation Medium (g / L) Sorbitol 20, Ammonium Chloride 2.0, Dipotassium Hydrogen Phosphate 1.5, MgSO 4 0.9, tryptone 1.5, pH 7.8.

[0027] Utilize 30L fermentation medium, adopt pH control method to ferment on 50L B.Braum mechanical stirring tank, inoculum size 4%, add a small amount of polyoxyethylene polyoxypropylene glyceryl ether (bubble enemy) to control the inoculum in the fermentation process before sterilization For foaming, the rotation speed of the fermenter is 300-500rpm, the ventilation rate is 30 L / min, the gauge pressure is 0.05Mpa, and the fermentation temperature is 37°C. The ammonia water to adjust the pH value is concentrated ammonia water, and the concentration of hydrochloric acid is 3M. The pH in the growth stage of the bacteria naturally drops to 6.4, and then the pH value is controlled at about 6.4 with ammonia water and h...

Embodiment 2

[0028] Example 2. Extraction of polysialic acid

[0029]Take 5L of fermented liquid, remove bacteria through plate and frame filtration, add 100-250g of sodium chloride (NaCl) to the resulting filtered clear liquid and stir to dissolve it, then add 2 to 4 times the volume of 95% of the clear liquid containing sodium chloride Mass concentration of ethanol, precipitate polysialic acid, and let it stand overnight, obtain polysialic acid precipitate by decantation or centrifugation, then wash with a small amount of 75% mass concentration ethanol for 2 to 4 times, and then dissolve the polysialic acid precipitate in an appropriate amount In deionized water, the obtained turbid liquid was filtered to remove part of the protein, and the obtained filtrate was adjusted to pH 7-8, and about 50 mL of alkaline protease (enzyme activity 2-50,000 U / mL) was added, and it was heated in a constant temperature water bath at 30-70 °C. Treat for 3-7 hours under the same conditions, then add exces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com