Process for producing platinum metal nano-particle for catalysis with polymer microsphere as carrier

A technology of polymer microspheres and nanoparticles, which is applied in the field of polymer materials and metal nanocatalytic materials, can solve the problems of reducing the application range of materials, and achieve the effects of preventing aggregation, good reusability, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

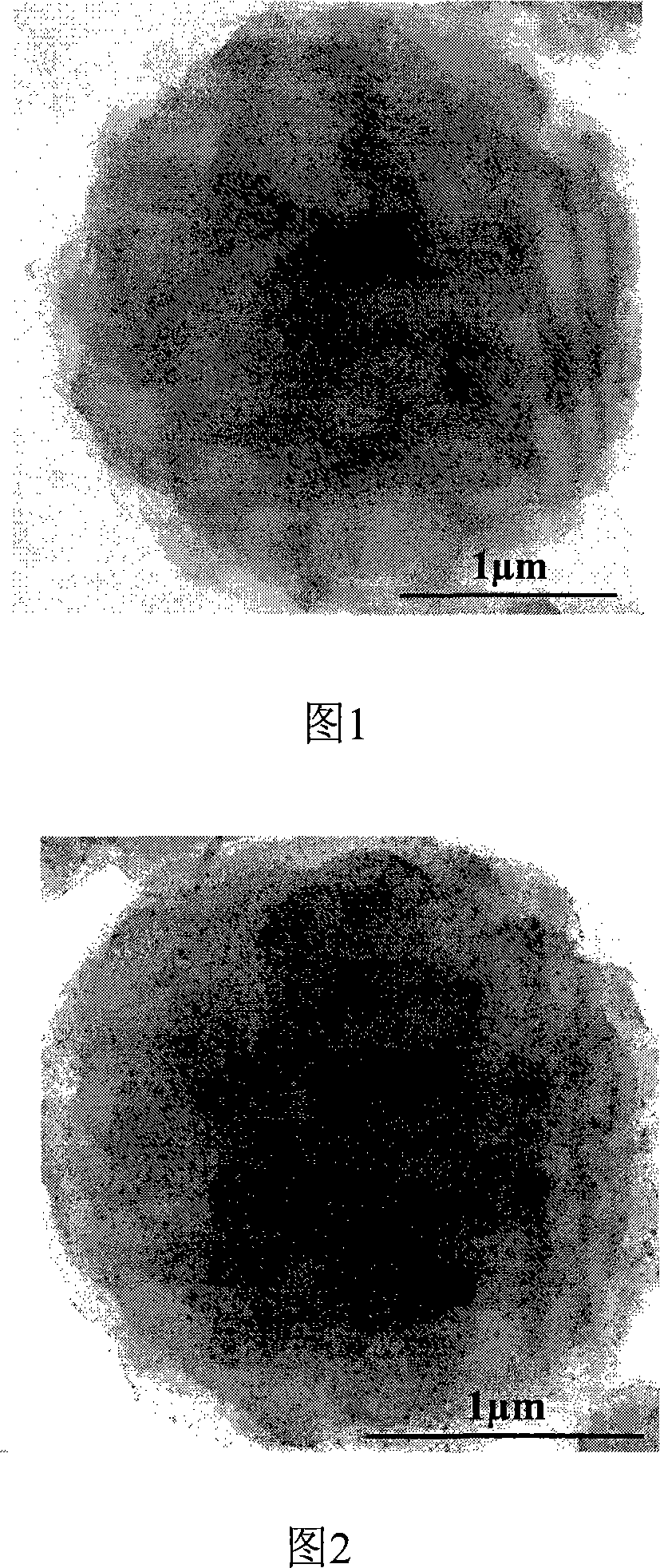

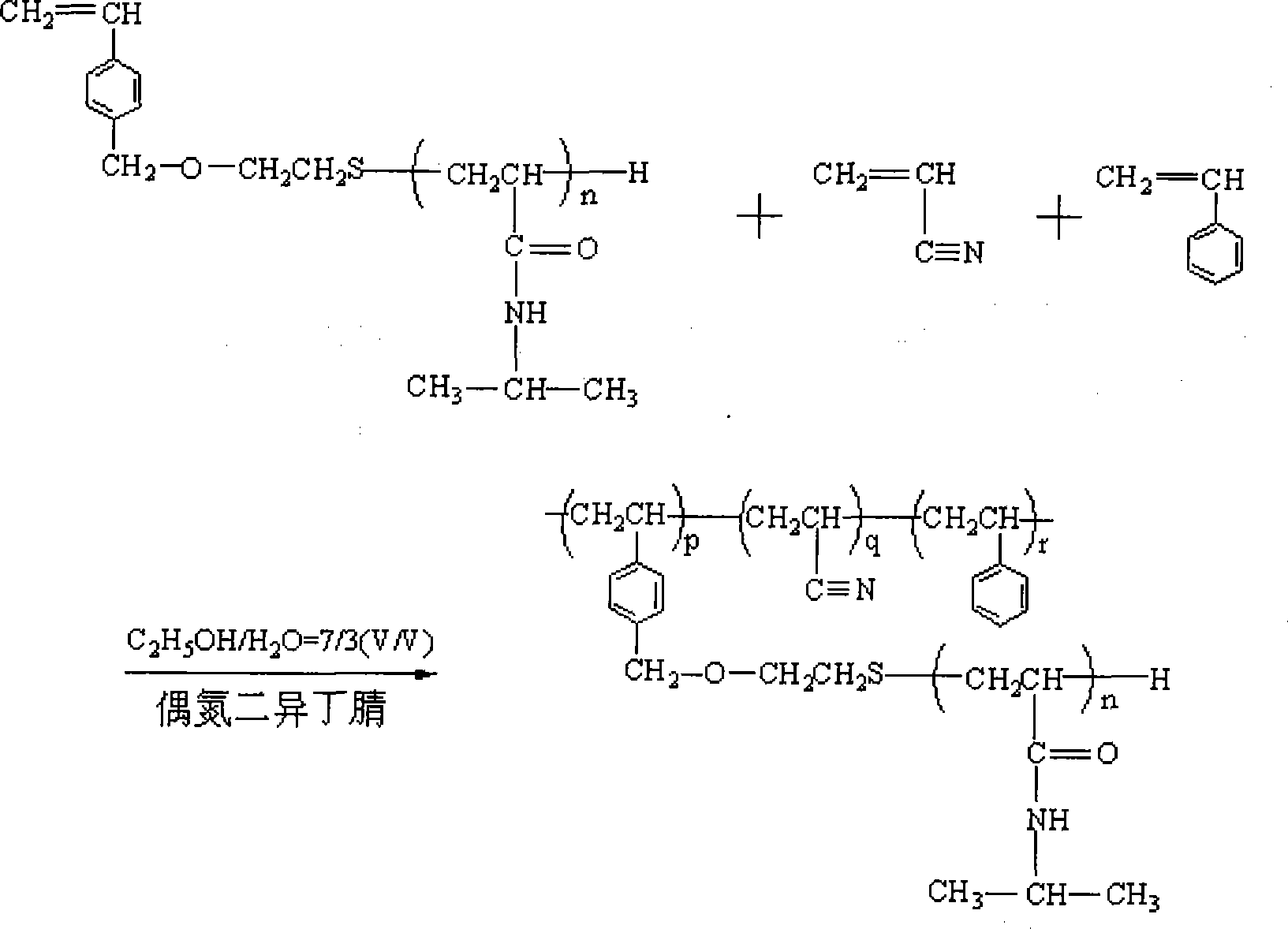

[0027] The first step: Add styrene-terminated poly-N-isopropylacrylamide 0.195mmol (8g) successively in a 50mL reactor at room temperature, and the number-average molecular weight of poly-N-isopropylacrylamide (PNIPAAm) macromonomer Mn=4×10 3 g / mol; styrene 4.5mmol (0.47g), acrylonitrile 15mmol (0.8g), azobisisobutyronitrile 0.195mmol (0.03mg), ethanol / water (volume ratio 7 / 3) mixed medium 25mL, ultrasonic Vibrate to fully dissolve the mixed solution, repeat three cycles of refrigerated vacuum and thawing, or continuously pass high-purity nitrogen gas for 30 minutes, then seal the reactor, stir at 60°C or keep the oscillation frequency at 160rpmin, and react for 22 hours. Take out the reactor, centrifuge the reaction solution, redisperse it in the water medium, further dialysis and purify in the cellulose dialysis membrane to remove impurities such as unreacted monomers, and freeze-dry to obtain polymer microspheres with special morphology on the surface.

[0028] The second ...

Embodiment 2

[0032] The first step: Add 0.195 mmol (1.3 g) of styrene-terminated poly-N-vinylacetamide successively in a 50 mL reactor at room temperature, and the number-average molecular weight of the poly-N-vinylacetamide (PNVA) macromer is Mn=6×10 3 g / mol; styrene 4.5mmol (0.5g), acrylonitrile 15mmol (0.8g), azobisisobutyronitrile 0.195mmol (0.03g), ethanol / water (volume ratio 7 / 3) mixed medium 25mL, ultrasonic Vibrate to fully dissolve the mixed solution, repeat three cycles of refrigerated vacuum and thawing or continue to pass high-purity nitrogen gas for 30 minutes, then seal the reactor, stir at 60°C or keep the oscillation frequency at 160rpmin, and react for 24 hours. Take out the reactor, centrifuge the reaction solution, redisperse it in the water medium, further dialysis and purify in the cellulose dialysis membrane to remove impurities such as unreacted monomers, and freeze-dry to obtain polymer microspheres with special morphology on the surface.

[0033] Step 2: Weigh 0.0...

Embodiment 3

[0037] Step 1: Add 0.195 mmol (1.0 g) of styrene-terminated polyacrylamide to a 50 mL reactor at room temperature, and the number-average molecular weight of the polyacrylamide (PAM) macromonomer is Mn=5×10 3 g / mol; styrene 4.5mmol (0.5g), acrylonitrile 15mmol (0.8g), azobisisobutyronitrile 0.195mmol (0.03Gg), ethanol / water (volume ratio 7 / 3) mixed medium 25mL, ultrasonic Vibrate to fully dissolve the mixed solution, repeat three cycles of refrigerated vacuum and thawing or continue to pass high-purity nitrogen gas for 30 minutes, then seal the reactor, stir at 60°C or keep the oscillation frequency at 160rpmin, and react for 26 hours. Take out the reactor, centrifuge the reaction solution, redisperse it in the water medium, further dialysis and purify in the cellulose dialysis membrane to remove impurities such as unreacted monomers, and freeze-dry to obtain polymer microspheres with special morphology on the surface.

[0038] Step 2: Weigh 0.0018mmol (0.1g) of the special-fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com