Method for producing nano-magnesium hydroxide by using low-level magnesite

A technology of nano-magnesium hydroxide and magnesium hydroxide, which is applied in the direction of magnesium hydroxide, can solve the problems of land resources occupied by magnesite, and achieve the effects of high utilization rate, good dispersion and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

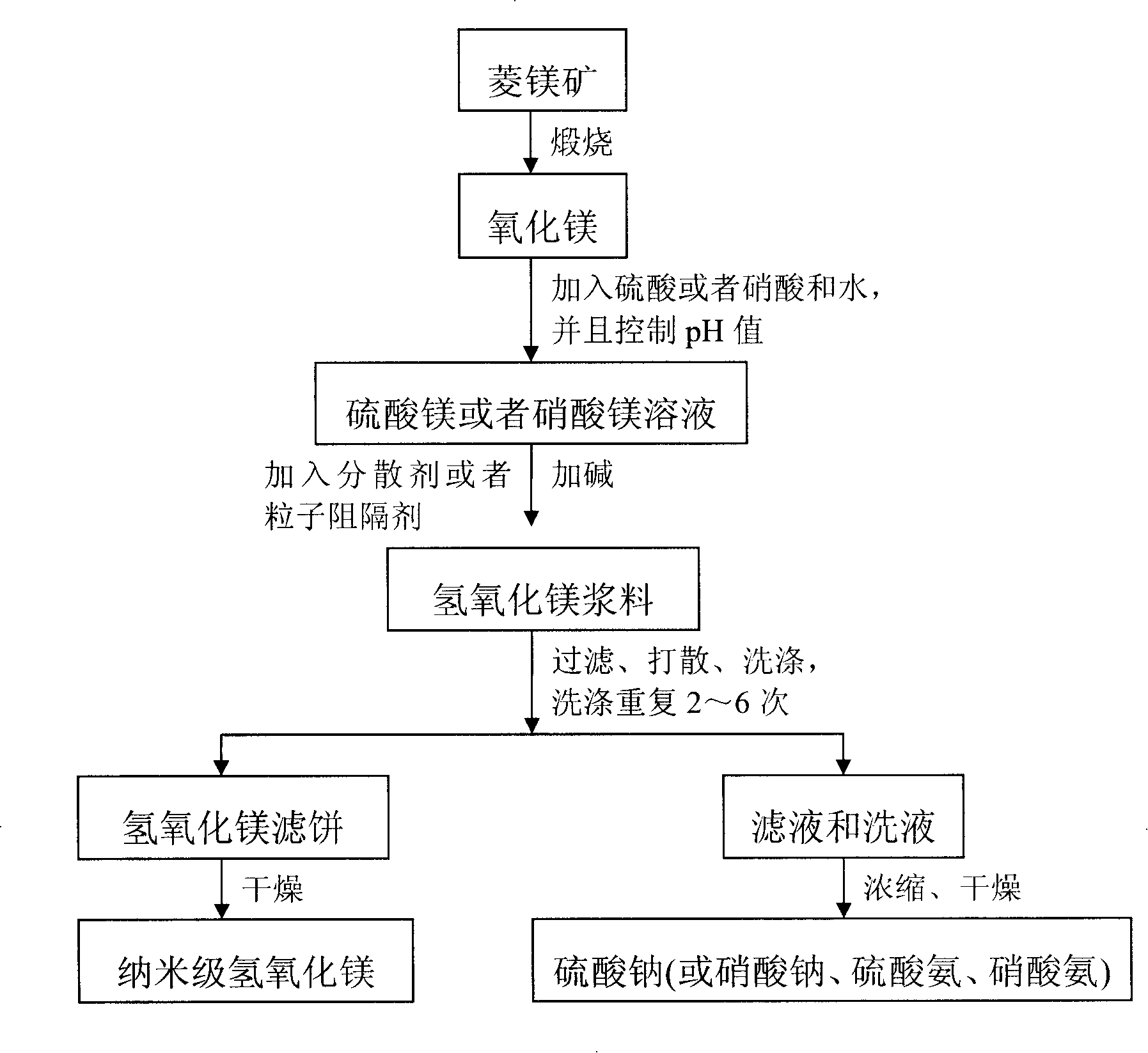

Method used

Image

Examples

Embodiment 1

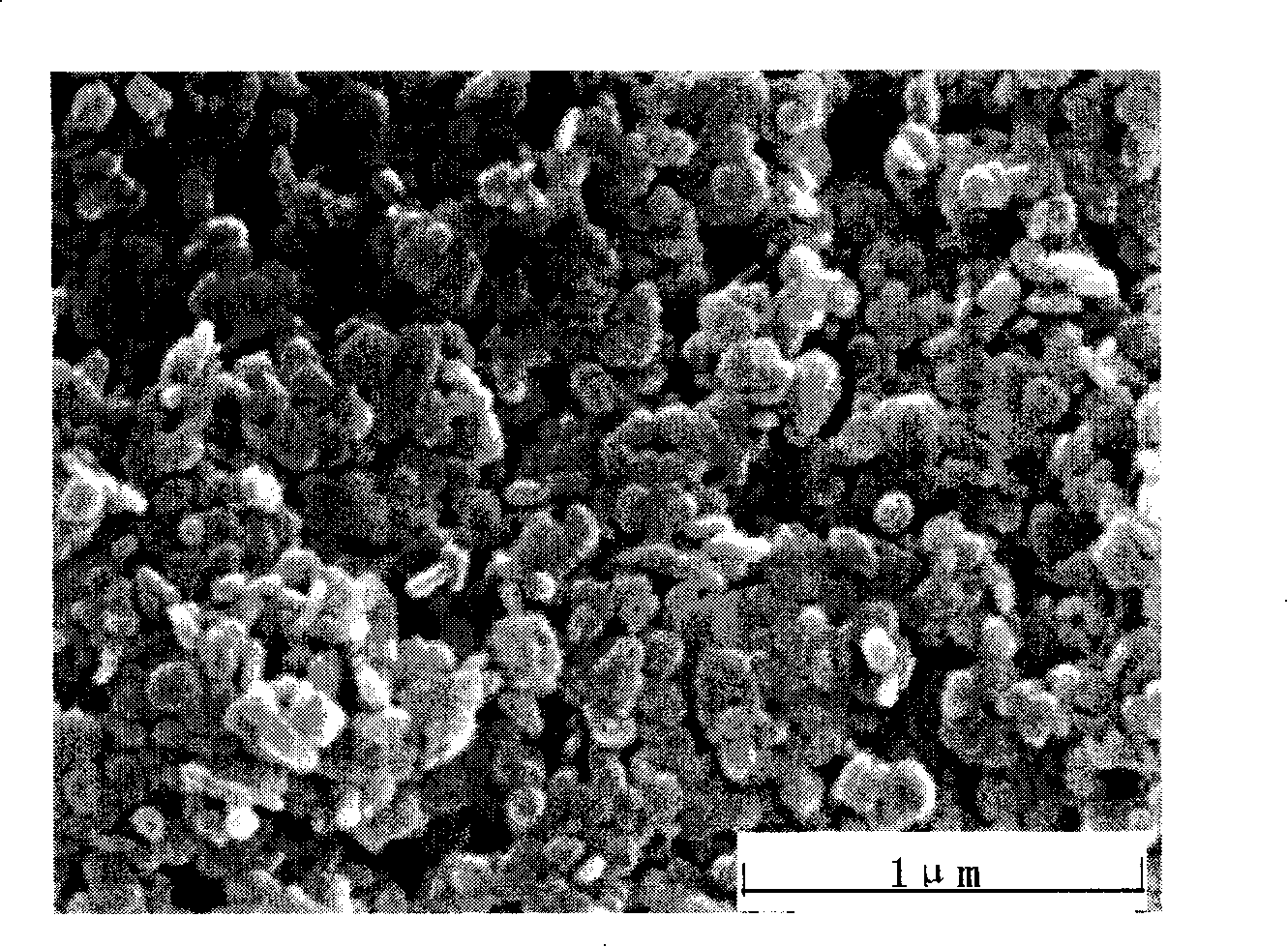

[0039] Take 120g of magnesite powder and calcinate at 1200°C for 20min; take it out and put it in a 1000mL beaker after cooling down, add 150g of water and 80g of 92% sulfuric acid, stir well, add sulfuric acid to adjust the pH to 3-7, filter; take the filtrate, Add 1.00 g of silane coupling agent (brand A-151), stir at 80 ° C, add alkali to react, the alkali solution is sodium hydroxide solution with a mass concentration of 30%, the reaction time is 15 minutes, and aging for 30 minutes after the reaction; Filter the reacted slurry, keep the mother liquor and filter cake; add distilled water to the filter cake to break up and then re-filter, repeat the process 4 times; dry and break up the filter cake to obtain the nano-magnesium hydroxide product; mix the mother liquor and each Sodium sulfate was obtained after the secondary wash was dried at 250°C.

[0040] Table 1 is the test results of the chemical components of the products obtained in the examples, and Table 2 is the tes...

Embodiment 2

[0046] Take 200g of magnesite powder and calcinate at 900°C for 30 minutes; take it out and put it in a 1000mL beaker after cooling down, add 200g of water and 135g of 70% nitric acid, stir well, add nitric acid to adjust the pH to 5-9, and filter; take the filtrate , add 0.500g of water-soluble polymer dispersant (the brand is A9400), stir at 20°C, add alkali to react, the alkali lye is an ammonia solution with a mass concentration of 30%, the reaction time is 15min, and aging for 30min after the reaction; The final slurry is filtered, and the mother liquor and filter cake are kept; the filter cake is dispersed by adding distilled water and re-filtered, and the process is repeated 4 times; the filter cake is dried and dispersed to obtain the nano-magnesium hydroxide product; the mother liquor and each washing The solution was dried at 80°C to obtain ammonium nitrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| H value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com