Method for preparing superhigh molecular weight polythene catalyst and application thereof

An ultra-high molecular weight, catalyst technology, applied in the production of bulk chemicals, etc., can solve the problem of low polymerization activity of catalysts, and achieve the effect of simple and feasible preparation method, stable polymerization reaction, and simplified polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (1) Preparation of new ecological magnesium compounds:

[0034] Under nitrogen protection, magnesium powder reacts with halogenated alkanes in alkane solvents to obtain the general formula (RMgX) y (MgX 2 ), wherein y=0.02-1, preferably 0.05-0.43, R is an alkyl group containing 3-12 carbons, X is halogen, preferably chlorine.

[0035] The reaction temperature is controlled at 10-100°C, preferably 20-80°C, and the reaction time is 0.5-10 hours, preferably 1-8 hours. After the reaction is completed, a new ecological magnesium compound is obtained, which is washed with a clean alkane solvent. The new eco-magnesium compound is dried several times to make it into a solid state for later use. The molar ratio of the magnesium powder to the halogenated alkane is 1: (1-3).

[0036] Alkane solvents are aliphatic hydrocarbons, alicyclic hydrocarbons and aromatic hydrocarbons, such as n-pentane, isopentane, n-hexane, n-octane, cyclopentane, cyclohexane, benzene, 1,2-dichloroetha...

Embodiment 1

[0065] (1) Preparation of new ecological magnesium chloride

[0066]Add 2.5L of hexane and 48g of magnesium powder into a 5L reactor equipped with pressure and temperature controllers and stirrers, add 418mL of n-chlorobutane into the reactor at 60°C for 3.0 hours, after the addition is complete , and continued to react at 60° C. for 4 hours to obtain a neoecological magnesium chloride solid suspension. Evaporate the hexane solvent at 70°C, add 3.0L tetrahydrofuran into the reactor after cooling, and stir evenly to obtain a new ecological magnesium chloride solution. After analysis, it can be seen that Mg: 1.6328mol / L, Cl: 2.8411mol / L, Cl / Mg=1.74, (BuMgCl) 0.35 (MgCl 2 );

[0067] (2) Preparation of main component of titanium-containing catalyst

[0068] Filter the solution obtained in step (1) into another 10L reactor, add 73ml of titanium tetrachloride, 124ml of diethylaluminum chloride, and 3.0L of tetrahydrofuran, heat up to 60°C and keep the reaction at this temperatu...

Embodiment 2

[0077] (1), (2) and (3) steps are with embodiment 1; It can be known that new ecological magnesium chloride is (BuMgCl) after analysis 0.02 (MgCl 2 );

[0078] Samples were taken for analysis, and the residual amount of tetrahydrofuran in the main component of the titanium-containing catalyst was 21 wt%.

[0079] (4) Preactivate the main component of the titanium-containing catalyst

[0080] Take out 18g from the main component of the solid titanium-containing catalyst prepared by the above method for pre-activation treatment, add 100mL of hexane solvent to dilute at room temperature, and then inject activator, wherein 3mL of tri-n-hexylaluminum, diethyl chloride Aluminum 3.5 mL (diethylaluminum chloride: tri-n-hexylaluminum = 2.5 (mol / mol)), stirred and mixed at 20°C for 2 hours.

[0081] Polymerization evaluation test:

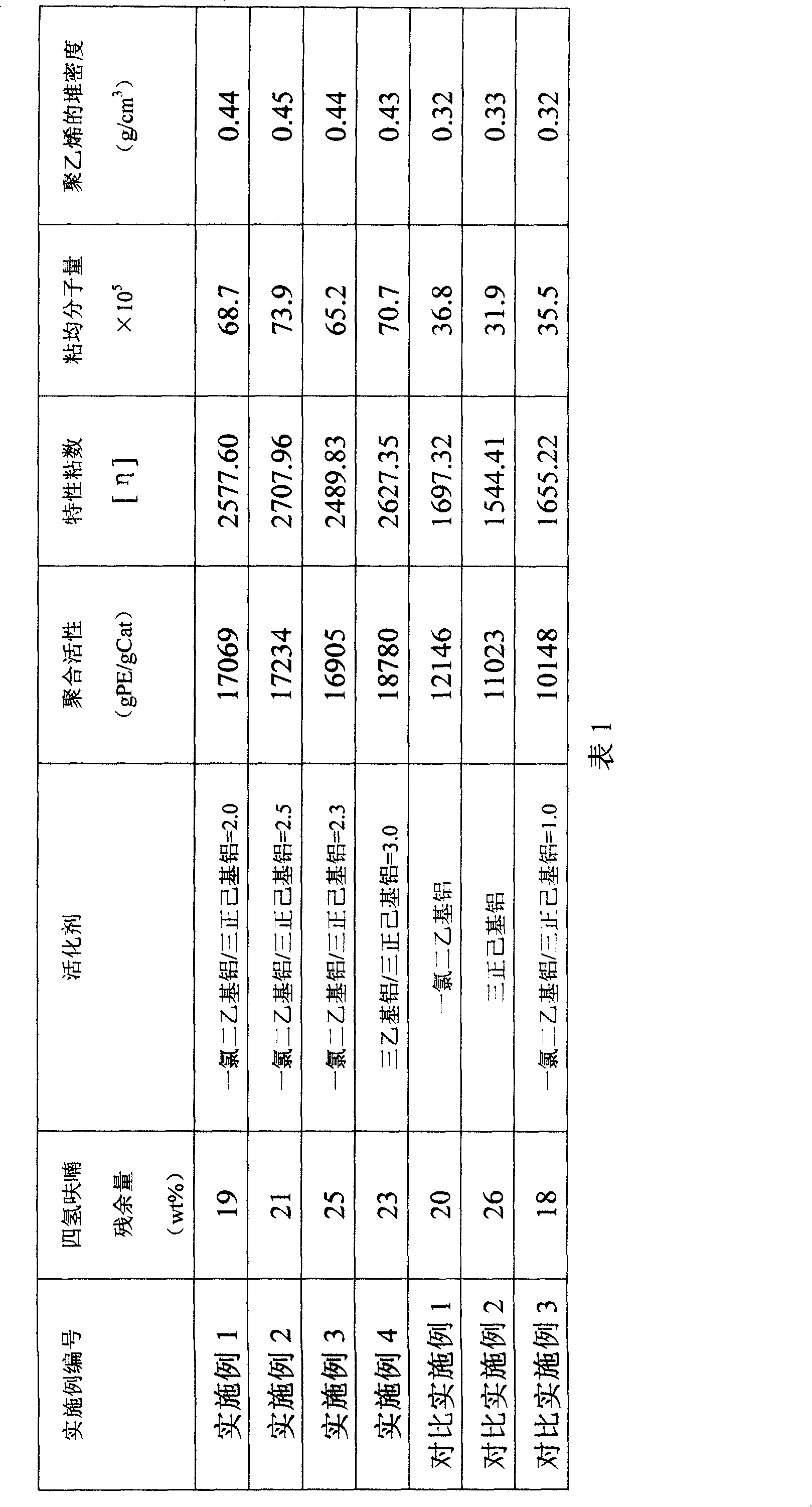

[0082] Same as Example 1, see Table 1 for the result data of catalyst polymerization evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com