Dielectric adjustable thin film based on implantation type nano line electrode and preparation thereof

A nanowire, implantable technology, applied in chemical instruments and methods, circuits, electrical components, etc., to achieve good application prospects, fewer defects, and less loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

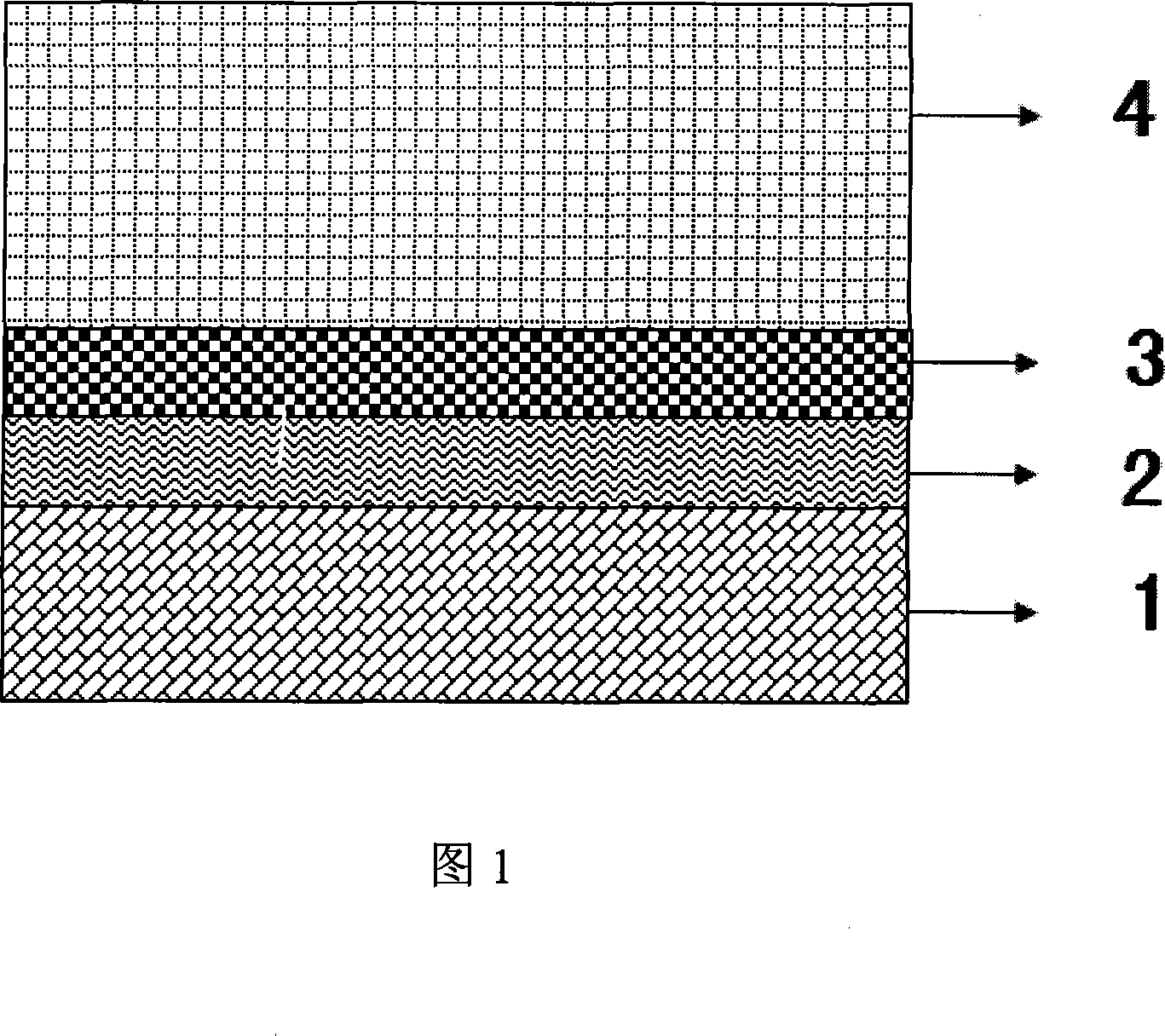

[0034] 1) According to the chemical formula Pb x Sr 1-x TiO 3 , x=0.4, take powdered strontium carbonate, lead oxide and titanium dioxide, in which the lead oxide is over 0.02% mol to compensate for the volatilization loss of lead; mix by ball milling, then press the target, and sinter the target material Pb 0.4 Sr 0.6 TiO 3 ;

[0035] 2) Clean the glass substrate, and sequentially deposit Ti on the substrate by chemical vapor deposition 5 Si 3 Conductive film layer and TiSi conductive nanowire layer;

[0036] 3) Sputtering deposition of a dielectric film Pb on the titanium silicide conductive nanowire layer of the composite structure obtained in step 2) by magnetron sputtering 0.4 Sr 0.6 TiO 3 ; During sputtering, the vacuum degree of the reaction chamber was kept at 0.6Pa, with argon and oxygen as the sputtering atmosphere, the flow rates of argon and oxygen were 10sccm and 10sccm respectively, the sputtering power was 80W, and the sputtering time was 2h;

[0037] ...

Embodiment 2

[0040] 1) According to the chemical formula Pb x Sr 1-x TiO 3 , x = 0.1, take powdered strontium carbonate, lead oxide and titanium dioxide, in which the lead oxide is over 0.02% mol to compensate for the volatilization loss of lead; mix by ball milling, then press the target, and sinter the target material Pb 0.1 Sr 0.9 TiO 3 ;

[0041] 2) Clean the single crystal silicon substrate, and sequentially deposit Ti on the substrate by chemical vapor deposition 5 Si 3 conductive film layer and TiSi 2 conductive nanowire layer;

[0042] 3) Sputtering deposition of a dielectric film Pb on the titanium silicide conductive nanowire layer of the composite structure obtained in step 2) by magnetron sputtering 0.1 Sr 0.9 TiO 3 ; During sputtering, the vacuum degree of the reaction chamber was kept at 0.8Pa, with argon and oxygen as the sputtering atmosphere, the flow rates of argon and oxygen were 3sccm and 27sccm respectively, the sputtering power was 60W, and the sputtering ti...

Embodiment 3

[0046] 1) According to the chemical formula Pb x Sr 1-x TiO 3 , x=0.9, take powdered strontium carbonate, lead oxide and titanium dioxide, in which the lead oxide is over 0.02% mol to compensate for the volatilization loss of lead; mix by ball milling, then press the target, and sinter the target material Pb 0.9 Sr 0.1 TiO 3 ;

[0047] 2) Clean the polysilicon substrate, and deposit Ti sequentially on the substrate by chemical vapor deposition 5 Si 3 Conductive film layer and TiSi conductive nanowire layer;

[0048] 3) Sputtering deposition of a dielectric film Pb on the titanium silicide conductive nanowire layer of the composite structure obtained in step 2) by magnetron sputtering 0.9 Sr 0.1 TiO 3 ; During sputtering, the vacuum degree of the reaction chamber was kept at 1Pa, with argon and oxygen as the sputtering atmosphere, the flow rates of argon and oxygen were 12sccm and 45sccm respectively, the sputtering power was 90W, and the sputtering time was 2h;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com