Lactobacillus acidophilus/enterococcus faecalis culture medium, preparations and technique

一种嗜酸乳杆菌、粪链球菌的技术,应用在链球菌/乳球菌、乳杆菌、双歧杆菌等方向,能够解决稳定性的效果不十分令人满意等问题,达到活菌收得率提高、提高稳定性、提高存活率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

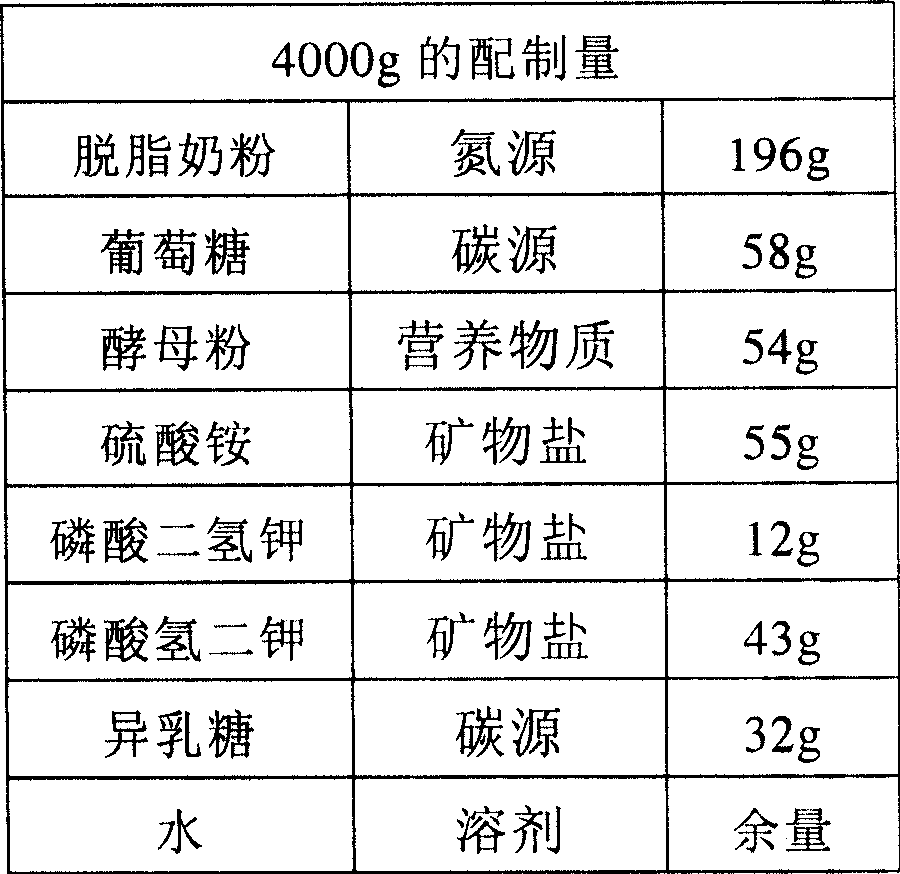

[0114] Embodiment 1: Preparation of the seed culture medium inoculated with Bifidobacterium longum

[0115] Use 500ml of pure water to dissolve the glucose (purchased from Hebei Shengxue Glucose Co., Ltd.), yeast powder (Germany MERCK KGAA.), ammonium sulfate (Jiangsu Yonghua Fine Chemicals Co., Ltd., AR grade), Potassium dihydrogen phosphate (Shantou Jinsha Chemical Factory Co., Ltd., AR grade), dipotassium hydrogen phosphate (Shantou Jinsha Chemical Factory Co., Ltd., AR grade) and allolactose (Italy INALCO S.P.A.) to obtain a solution. And use 1500ml of pure water to beat the skimmed milk powder (FONTERRALTD., New Zealand) of the quantity shown in the following table 1 with a homogenizer (Shanghai Specimen Model Factory, DS-1) to obtain a suspension.

[0116] Above-mentioned solution and suspension are put into the seed bottle after colloid mill (Wenzhou Lucheng Emulsification Machinery Company, JM-L80) grinds evenly, then add to 4000g with drinking water and prepare the ...

Embodiment 2

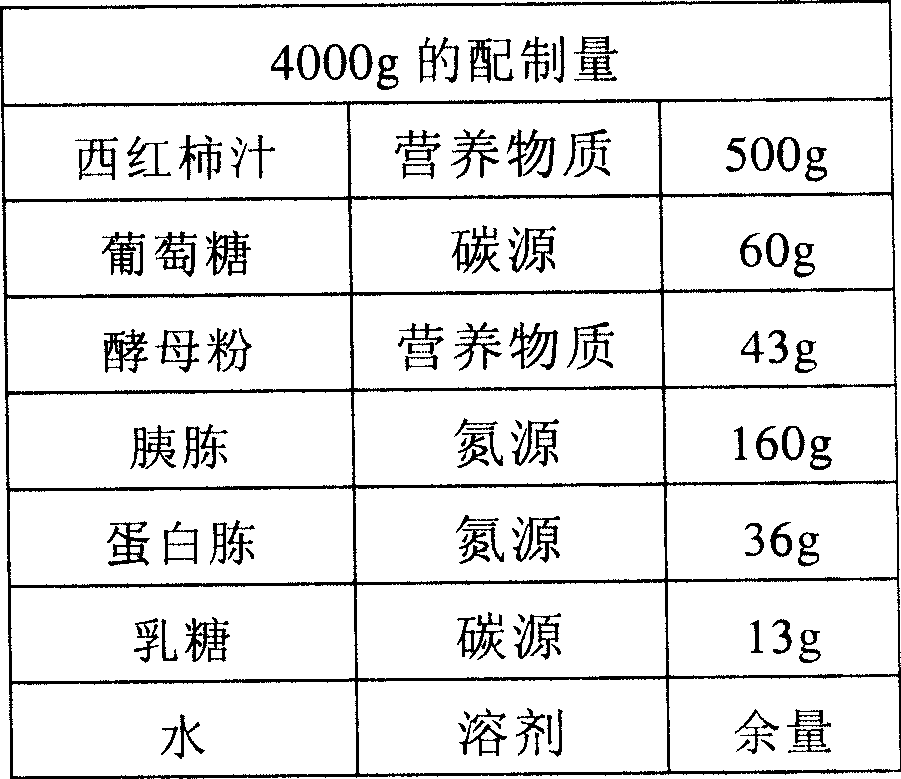

[0121] Embodiment 2: Preparation of the seed culture medium inoculated with Lactobacillus acidophilus and Streptococcus faecalis

[0122] Use 500ml of pure water to dissolve the glucose (Hebei Shengxue Glucose Co., Ltd.), yeast powder (Germany MERCK KGAA.), lactose (Shanghai Shenmei Pharmaceutical Development Technology Co., Ltd.), tomato juice (Shanghai Pudong New Area Jinyang Street Xinxin Non-staple Food Business Department), to get the solution. And use 1500ml of pure water to beat the tryptone (German MERCK KGAA.) and peptone (Nippon Pharmaceutical Co., Ltd.) in the quantity shown in the following table 2 with a homogenizer (Shanghai Specimen Model Factory, DS-1) to obtain a suspension.

[0123] Put the above solution and suspension into the seed bottle after being uniformly ground by a colloid mill, then add drinking water to 4000g to prepare the seed medium of Bifidobacterium longum, and then add a little dilute sodium hydroxide solution to adjust the pH of the medium...

Embodiment 3

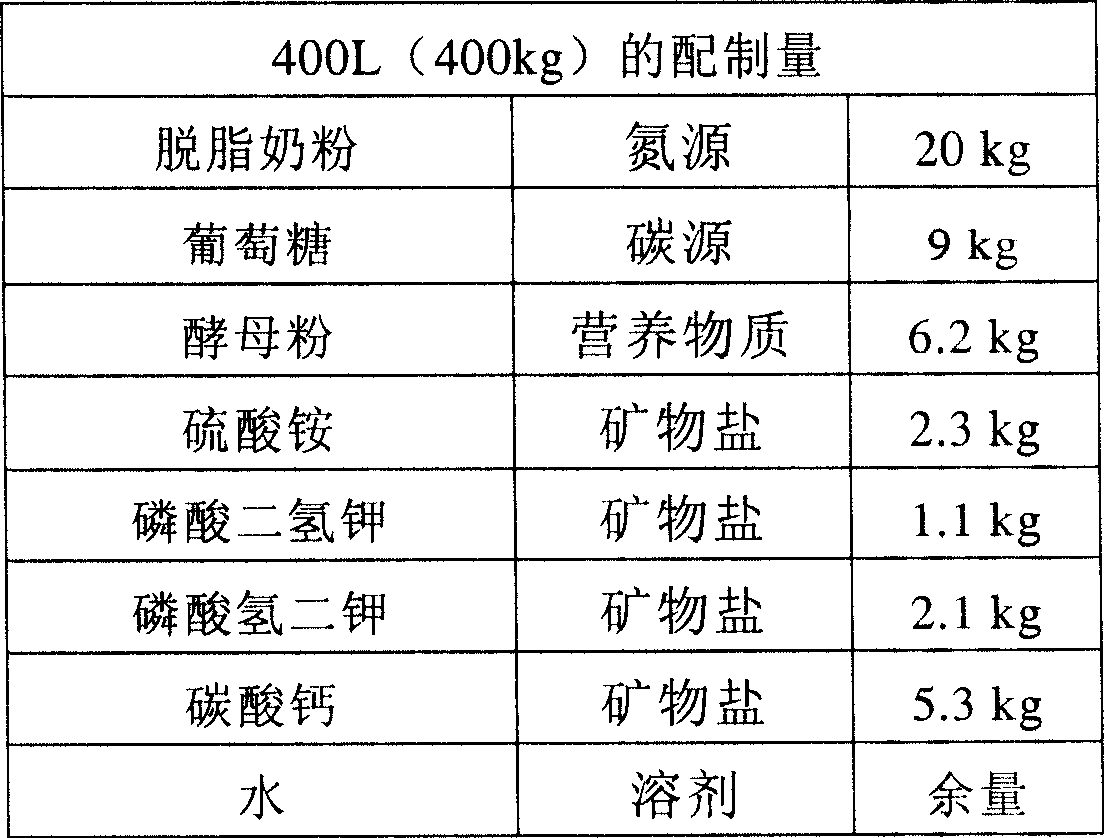

[0128] Embodiment 3: make each bifidobacterium longum fermentation medium

[0129] Pour the components shown in Table 3 below except calcium carbonate into a stainless steel bucket, then pour 30 kg of drinking water into the stainless steel bucket, and stir with a stainless steel rod at the same time to obtain a suspension of the culture medium. Pour the resulting suspension into a colloid mill and grind evenly. Pour the uniformly ground suspension into a fermenter equipped with a stirrer, and replenish to 400kg with water. Turn on the fermenter mixer, adjust the pH value of the medium with NaOH, then add the calcium carbonate shown in Table 3 below, and add water to 400kg at the same time to obtain the fermentation medium. The fermentation culture was sterilized based on 121°C for 10-15 minutes.

[0130] table 3

[0131] 400kg preparation amount

[0132] components Prescription 1 Prescription 2 Prescription 3 Prescription 4 Prescription 5 skimme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com