Novel composite electromagnetic shielding latex paint and preparation thereof

A technology of electromagnetic shielding and latex paint, applied in the direction of conductive paint, magnetic/electric field shielding, latex paint, etc., to achieve the effect of simple preparation method, high cost performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

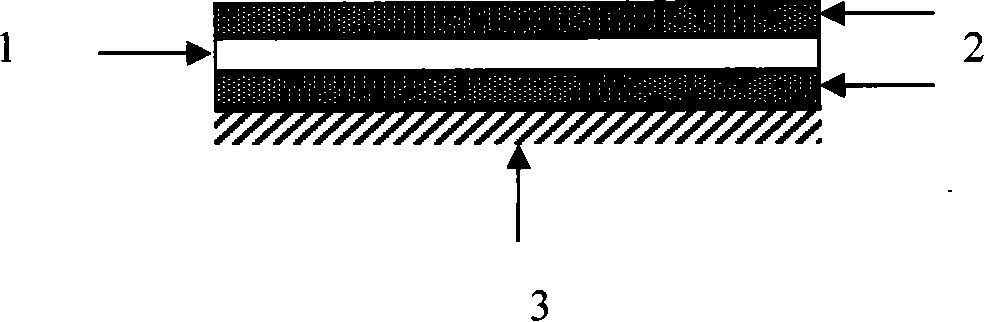

Image

Examples

Embodiment 1

[0040] The technological process and process parameters of the present embodiment are as follows:

[0041] 1. Ingredients

[0042] The formula (parts by weight) of the conductive layer coating is as follows:

[0043] Pure acrylate copolymer emulsion 50 parts

[0044] 30 parts of conductive nickel powder with a particle size of micron and a purity of more than 99.7%

[0045] Ethylene glycol butyl ether acetate 3 parts

[0046] 1.5 parts of hydroxyethyl cellulose

[0047] Inorganic bentonite 1.5 parts

[0048] 14 parts of purified water

[0049] The formula (parts by weight) of insulating interlayer paint is as follows:

[0050] Pure acrylate copolymer emulsion 90 parts

[0051] Ethylene glycol butyl ether acetate 4 parts

[0052] 1 part hydroxyethyl cellulose

[0053] 5 parts purified water

[0054] 2. Preparation of coating

[0055] (1) Preparation of the conductive layer part

[0056] Dry the originally prepared micron-sized nickel powder at a drying temperature o...

Embodiment 2

[0063] The technological process and process parameters of the present embodiment are as follows:

[0064] 1. Ingredients

[0065] The formula (parts by weight) of the conductive layer coating is as follows:

[0066] Styrene-acrylate copolymer emulsion 55 parts

[0067] Micron-sized conductive nickel powder 30 parts

[0068] Ethylene glycol butyl ether acetate 3 parts

[0069] Hydroxyethyl cellulose 0.5 parts

[0070] Inorganic bentonite 1.5 parts

[0071] 10 parts of purified water

[0072] The formula (parts by weight) of insulating interlayer paint is as follows:

[0073] Styrene-acrylate copolymer emulsion 90 parts

[0074] Ethylene glycol butyl ether acetate 3 parts

[0075] 31 parts of hydroxyethyl cellulose

[0076] 7 parts purified water

[0077] 2. Preparation of coating

[0078] (1) Preparation of the conductive layer part

[0079] Dry the originally prepared micron-sized nickel powder at a drying temperature of 70°C, and then mix styrene-acrylate copolym...

Embodiment 3

[0086] The technological process and process parameters of the present embodiment are as follows:

[0087] 1. Ingredients

[0088] The formula (parts by weight) of the conductive layer coating is as follows:

[0089] Pure acrylate copolymer emulsion 45 parts

[0090] Micron nickel powder 35 parts

[0091] 2 parts propylene glycol butyl ether

[0092] Methyl hydroxyethyl cellulose 1.0 parts

[0093] Inorganic bentonite 2 parts

[0094] 15 parts of purified water

[0095] The formula (parts by weight) of insulating interlayer paint is as follows:

[0096] Styrene-acrylate copolymer emulsion 91 parts

[0097] 2 parts propylene glycol butyl ether

[0098] 3 parts methyl hydroxyethyl cellulose

[0099] 5 parts purified water

[0100] 2. Preparation of coating

[0101] (1) Preparation of the conductive layer part

[0102] Dry the originally prepared micron-sized nickel powder, the optimal drying temperature is 60°C, and then mix pure acrylate copolymer emulsion, propylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com