Preparation and application of nylon affinity membrane with reactive blue 4 as ligand

An affinity membrane, nylon membrane technology, applied in the field of nylon affinity membrane, can solve the problems of low sample activity recovery rate, cumbersome operation, unsatisfactory purification effect, etc., to facilitate large-scale extraction and purification, simple operation, and convenient sample source. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

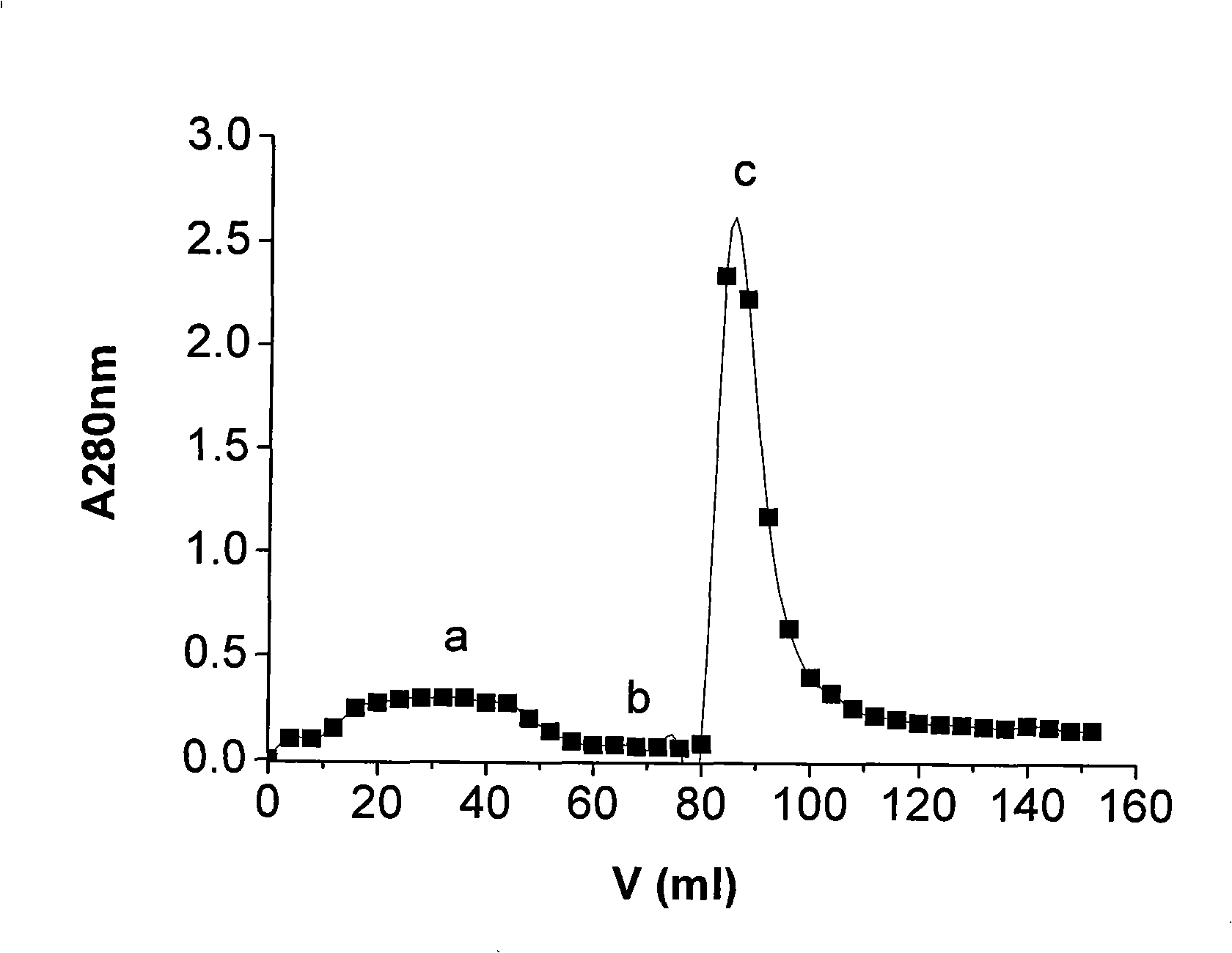

Image

Examples

Embodiment 1

[0027] The activation of the nylon membrane and the modification of the bonded chitosan, the specific steps are as follows:

[0028] (1) The nylon membrane was first hydrolyzed in 1mol / L HCl at 25°C for 24 hours, and then activated with formaldehyde. 10 sheets of hydrolyzed nylon

[0029] The membrane was immersed in 20mL formaldehyde solution (>36.5wt.%), added with 0.2mL phosphoric acid (85wt.%), reacted at 60°C for 7h, and washed with hot water at 40-50°C for several times.

[0030] (2) Immerse the above-mentioned formaldehyde-activated nylon membrane into 10 mL of chitosan solution (dissolved with 1 vol.% acetic acid) with a mass fraction of 2%, react at room temperature for 1 h, then transfer to an oven at 80 ° C, take it out after 1 h, and use 1 vol. .% acetic acid and deionized water to wash away unreacted chitosan. The content of chitosan on the nylon film can be tested according to the ninhydrin method.

Embodiment 2

[0032] The specific steps for the preparation of a nylon affinity membrane with Reactive Blue 4 as a ligand are as follows:

[0033] The above-mentioned nylon membrane modified by chitosan was immersed in the Reactive Blue 4 dye solution with a concentration of 10mg / mL, and kept at 60°C for 40 minutes, then added a 20% NaCl solution by mass fraction, reacted with constant temperature oscillation for 30 minutes, and then raised the temperature of the water bath to 80°C, add a mass fraction of 25% Na 2 CO 3 solution, continue to react at constant temperature for 4 hours, and wash with hot deionized water, methanol solution with a volume fraction of 10%, 2mol / L NaCl solution, 6mol / L urea solution and deionized water until the washing solution is colorless , to obtain a nylon affinity membrane with Reactive Blue 4 as a ligand, and store it in double distilled water.

Embodiment 3

[0035] The characterization of the enzyme activity by ultraviolet spectrophotometry using casein as a substrate, the specific steps are as follows:

[0036] Take 0.1mL enzyme solution, add 0.7mL 0.05mol / L Tris-HCl buffer solution (pH 8.0), then add 0.2mL papain activator (the above buffer solution contains 0.5mol / L L-cysteine and 0.02mol / L of EDTA, pH 8.0) kept constant at 35°C, added 1mL of the same preheated 1% (W / V) casein solution (prepared by the above buffer), reacted at 35°C for 15mim, added 3mL of 5% trichloroacetic acid ( TCA) solution to terminate the reaction (in the control group, TCA was added first and then the substrate was added). Let it stand still, centrifuge at 8000 rpm for 20 minutes, and take the filtrate for colorimetry at a wavelength of 280nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com