Special-purpose nylon material for automobile intake manifold and processing method thereof

An intake manifold, nylon technology, used in chemical instruments and methods, liquid crystal materials, etc., to achieve the effects of excellent mechanical properties, reduced fracture rate, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

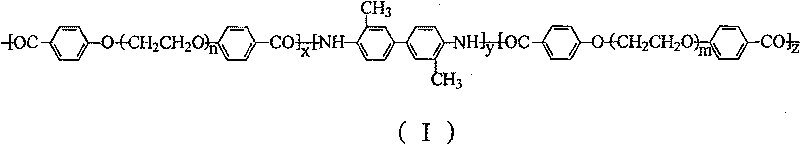

[0031] 1) Take the polyethylene glycol bis-4-carboxyphenyl ether (PEG) that has been strictly dried respectively. 2 ) 242.2g, polyethylene glycol bis-4-carboxyphenyl ether (PEG 3 ) 117g, o-toluidine (OT) 212g, anhydrous lithium chloride (LiCl) 200g, refined triphenyl phosphite (TPP) 620.6g, pyridine (PY) 1000ml, N-methylpyrrolidone (NMP) 4000ml, of which PEG 2 、PEG 3 The ratio of the amount of substances of the three monomers of , OT is 0.7 / 0.3 / 1, in N 2 Reaction at 110°C for 4 hours under protection, followed by precipitation in methanol, filtration and vacuum drying for 24 hours to obtain a thermotropic liquid crystal polyamide (a) with a melting point of 260°C, its structural formula is as follows:

[0032]

[0033] 2) Nylon 66, glass fiber, thermotropic liquid crystal polyamide (a) and processing aid are mixed uniformly in a weight percentage of 60 / 30 / 8 / 2, wherein the proportion of each component of the processing aid in the nylon material is The weight percentages ...

Embodiment 2

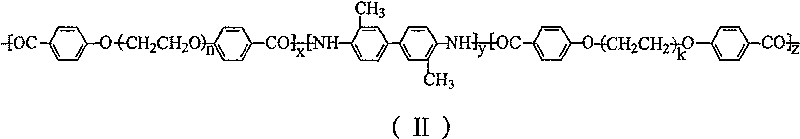

[0040] 1) Take the polyethylene glycol bis-4-carboxyphenyl ether (PEG) that has been strictly dried respectively. 2 ) 173g, 4'4-dicarboxy-α, ω-diphenoxyhexane 221g, o-toluidine (OT) 212g, anhydrous lithium chloride (LiCl) 200g, refined triphenyl phosphite ( TPP) 620.6g, pyridine (PY) 1000ml, N-methylpyrrolidone (NMP) 4000ml, of which PEG 2, 4'4-dicarboxy-alpha, omega-diphenoxy hexane, the ratio of the amount of three kinds of monomers of OT is 0.5 / 0.5 / 1, in N 2 Reaction at 110°C for 4 hours under protection, followed by precipitation in methanol, filtration and vacuum drying for 24 hours to obtain a thermotropic liquid crystal polyamide (b) with a melting point of 270°C, its structural formula is as follows:

[0041]

[0042] 2) Nylon 6, glass fiber, thermotropic liquid crystal polyamide (b) and processing aid are mixed evenly with a weight percentage of 53.5 / 30 / 15 / 1.5, wherein the proportion of each component of the processing aid in the nylon material is The weight perc...

Embodiment 3

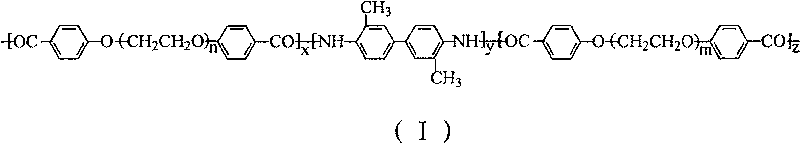

[0049] 1) Take the strictly dried polyethylene glycol bis-4-carboxyphenyl ether (PEG 3 ) 195g, 4'4-dicarboxy-α, ω-diphenoxyoctane 235g, o-toluidine (OT) 212g, anhydrous lithium chloride (LiCl) 200g, refined triphenyl phosphite ( TPP) 620.6g, pyridine (PY) 1000ml, N-methylpyrrolidone (NMP) 4000ml, of which PEG2, 4'4-dicarboxy-α, ω-diphenoxyoctane, OT three monomer substances The amount ratio is 0.5 / 0.5 / 1, at N 2 Reaction at 110°C for 4 hours under protection, followed by precipitation in methanol, filtration and vacuum drying for 24 hours to obtain a thermotropic liquid crystal polyamide (c) with a melting point of 224°C, its structural formula is as follows:

[0050]

[0051] 2) Mix evenly with nylon 11, glass fiber, thermotropic liquid crystal polyamide (c) and processing aid at a weight percentage of 61.4 / 30 / 7 / 1.6, wherein the proportion of each component of the processing aid in the nylon material is The weight percentages are as follows:

[0052] Anti-aging agent and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com