Method for preparing AB5 type hydrogen-storage alloy directly from metal oxide mixture

A technology for hydrogen storage alloys and oxides, which is applied in the field of solid oxygen-permeable membrane electrolysis to prepare alloys, can solve the problems of reducing agent and by-product removal troubles, accelerating the alloying process, and not being able to absorb hydrogen, so as to save raw material costs, Simplify the preparation process and reduce the effect of stringent requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

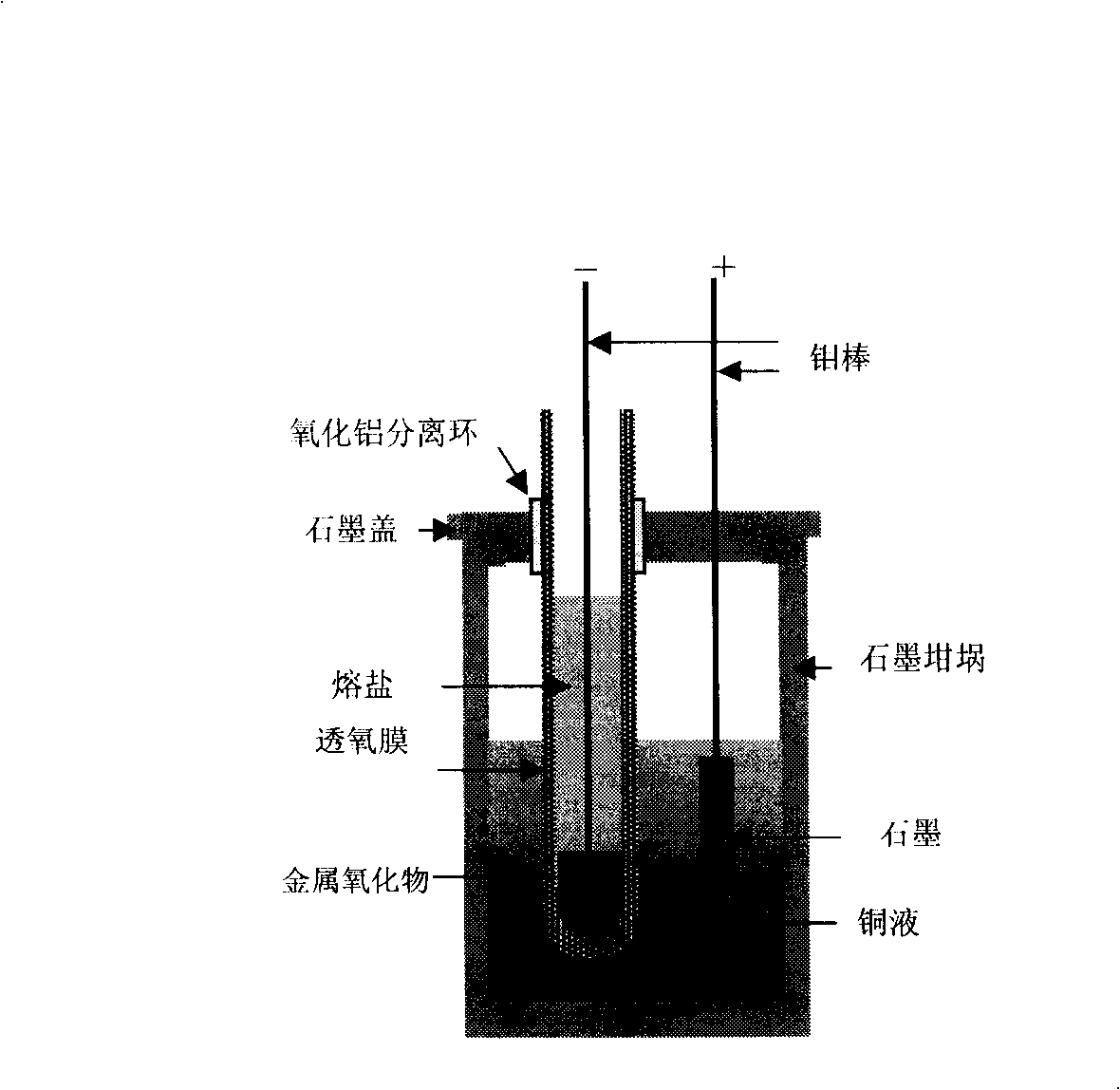

[0021] For the existing commonly used devices used in this embodiment, see figure 1 . figure 1 Schematic diagram of a graphite crucible electrolytic cell for the preparation of alloys by the SOM method.

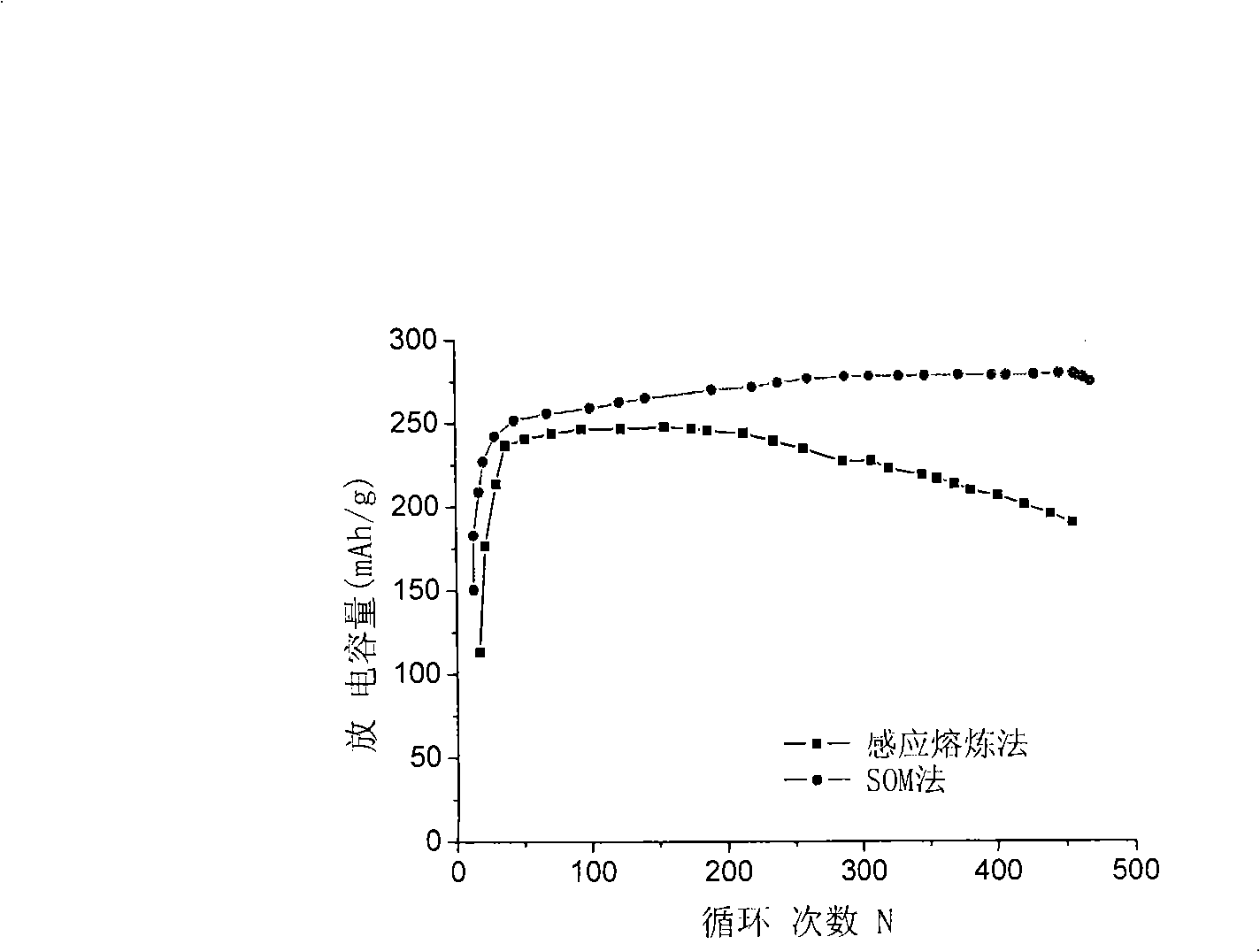

[0022] Mix the mixture dough in proportion (La 2 o 3 : 18.1±0.46wt%, CeO 2 : 8.54±0.28wt%, Pr 2 o 3 : 0.73±0.18wt%, Nd 2 o 3 : 2.46±0.18wt%, MnO 2 : 6.42±0.24wt%, Al 2 o 3 : 1.77±0.30wt%, Co 2 o 3 : 11.17±0.22wt%, NiO: the remainder) was sintered at 1000°C for 8h; then pressed into a disc shape, the cathode system composed of the disc and molybdenum rods was placed at the bottom of the oxygen permeable membrane, and then filled with 80g MgF 2 -CaF 2 Molten salt whose composition is 55.5% MgF 2 -44.5%CaF 2(mass fraction); after heating the crucible to 1100°C, connect the graphite anode and the metal oxide cathode guide rod at the bottom of the oxygen-permeable film to the positive and negative poles of the DC power supply respectively; carry out electrolysis, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com