Method for preparing cobaltic-cobaltous oxide powder with octahedron shape

A technology of tricobalt tetroxide powder and octahedron, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of wide particle size distribution and the inability to meet the production of high-quality lithium cobaltate products, and achieve complete crystallization, improved washing efficiency, and prevention of hydrolysis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

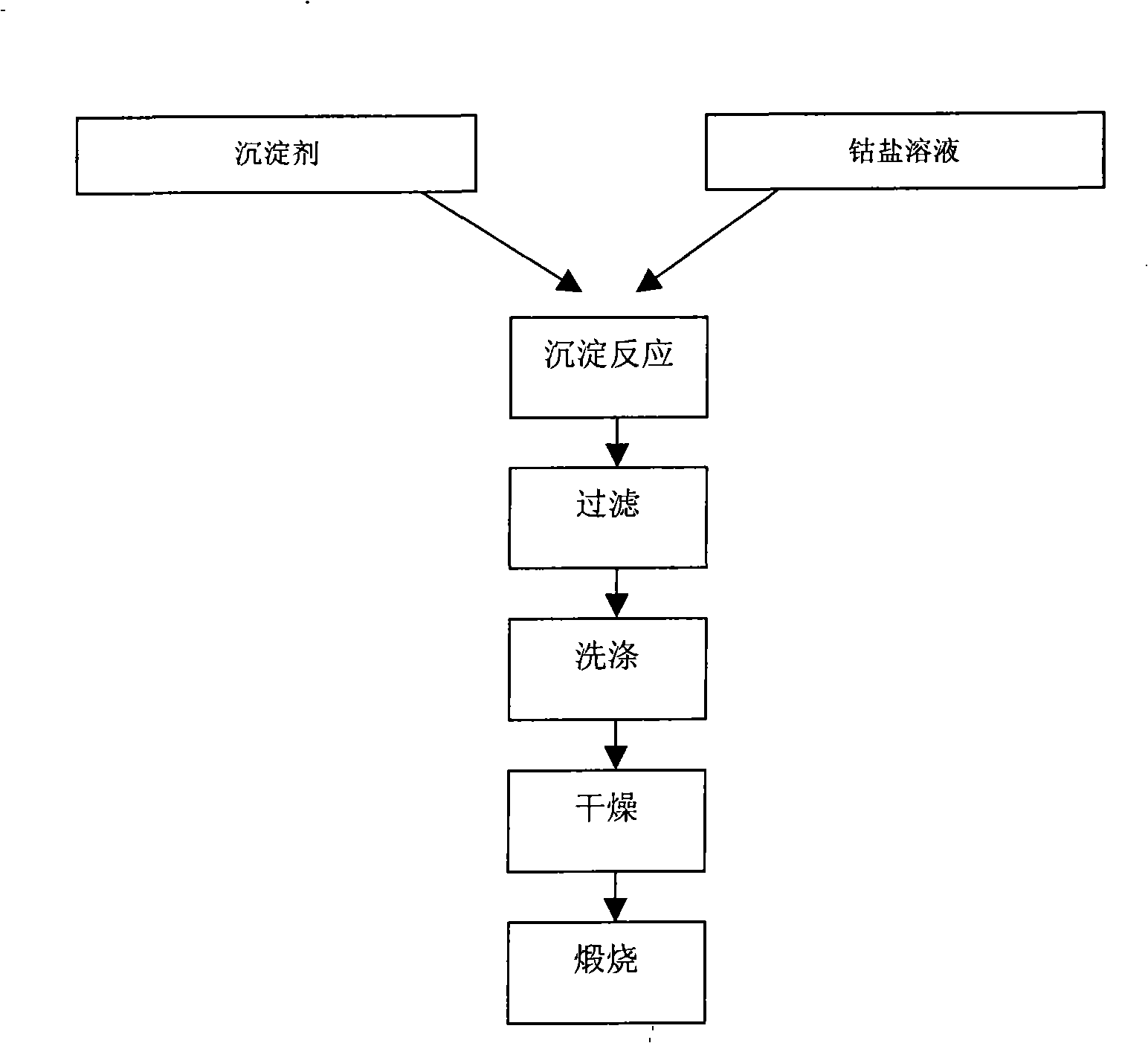

[0026] The preparation method of the present invention is to add soluble cobalt salt solutions such as cobalt chloride, cobalt acetate or cobalt nitrate and ammonium bicarbonate or ammonium carbonate solution into the reactor at a certain speed, stir vigorously at the same time, and strictly control the reaction temperature and The pH value is within a certain range to control the crystallization process. The obtained cobalt carbonate precursor is washed, filtered, dried at a certain temperature, and then calcined at a certain temperature to obtain the final octahedral cobalt tetroxide powder. The process flow diagram of the present invention is as figure 1 As shown, the specific steps are:

[0027] Preparation of solution

[0028] a preparation of soluble cobalt salt solution

[0029] Soluble cobalt salts such as cobalt chloride, cobalt acetate or cobalt nitrate are used as raw materials, dissolved in deionized water to form an aqueous solution with a cobalt ion concentrat...

Embodiment 1

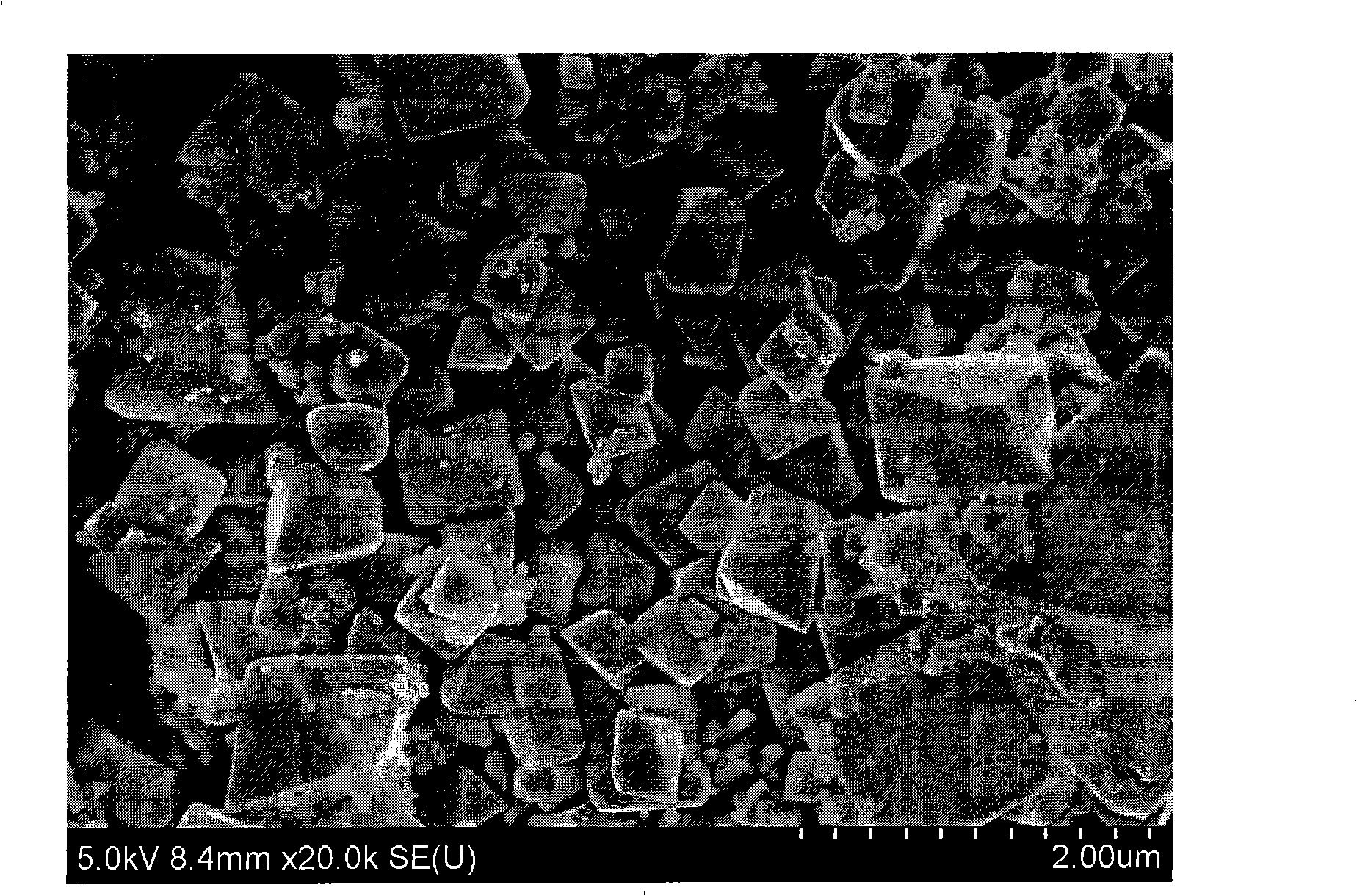

[0039]Prepare 10L of cobalt chloride solution with a cobalt ion concentration of 2mol / L, and 20L of ammonium bicarbonate solution with a concentration of 2mol / L. First add 2L of deionized water to a reactor with a volume of 50L, heat it to 40°C, and add the above solution into the reactor at the same time under the stirring condition of 200-2000r / min, and the cobalt salt solution is added at a speed of 20L / h 1. The ammonium bicarbonate solution was added at a rate of 40L / h, the reaction temperature was 40°C, and the pH value was controlled at 6.7. After the addition was completed, the reaction was continued for 30 minutes, aged at 40°C for 4 hours, and the cobalt carbonate precursor was suction filtered or pressed. filter, and wash the precipitate by suction filtration or pressure filtration, spin dry after washing, dry at 100°C for 8 hours, and finally calcinate at 600°C for 2 hours. The finally obtained cobalt tetroxide powder has a median diameter (D50) of 2.2 μm and a bulk...

Embodiment 2

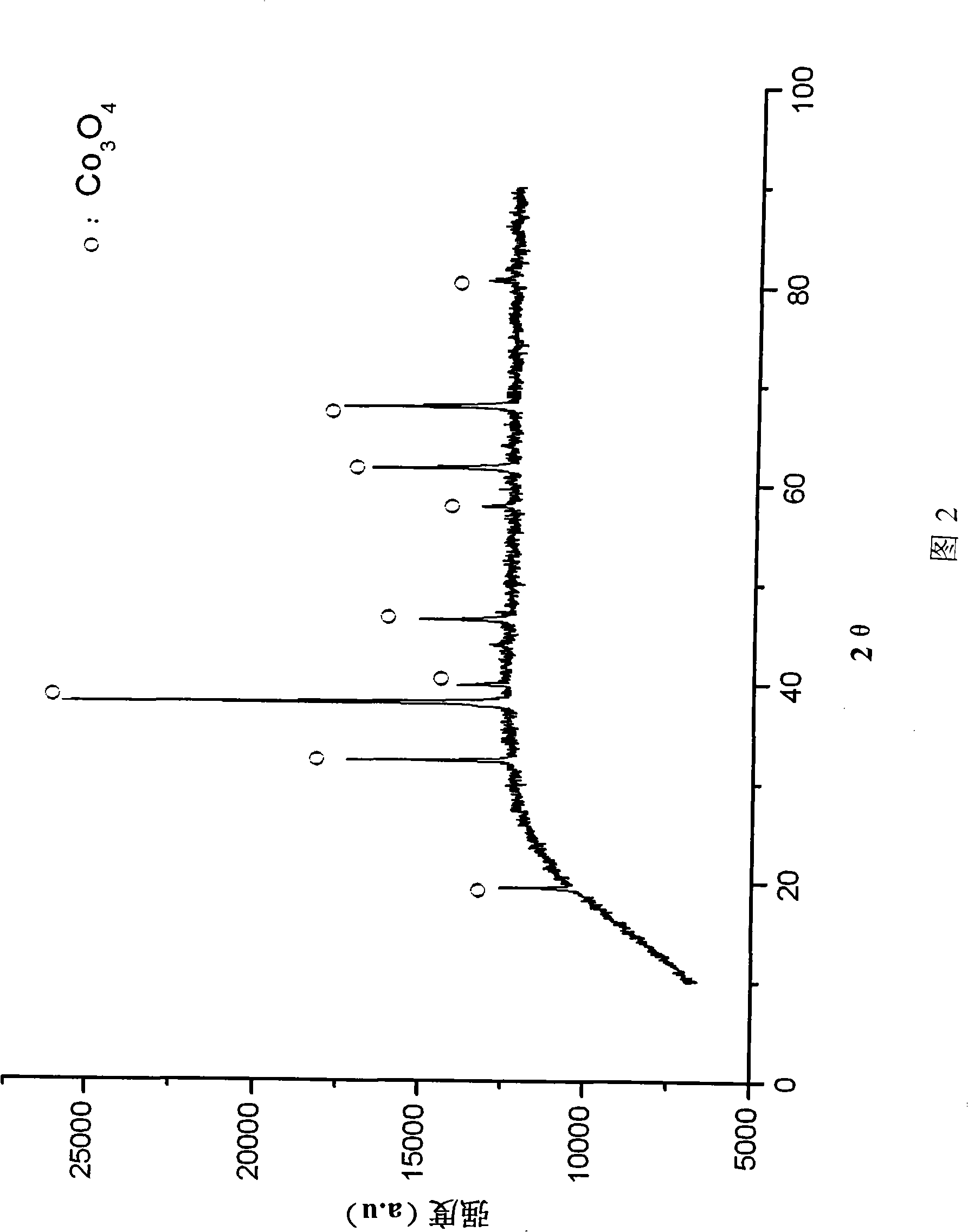

[0041] Prepare 20 L of cobalt chloride solution with a cobalt ion concentration of 0.5 mol / L, and 20 L of ammonium bicarbonate solution with a concentration of 1 mol / L. First add 2L of deionized water to a reactor with a volume of 50L, heat it to 80°C, and add the above solution into the reactor at the same time under the stirring condition of 200-2000r / min, and the cobalt salt solution is added at a rate of 100L / h 1. The ammonium bicarbonate solution was added at a rate of 100L / h, the reaction temperature was 80°C, and the pH value was controlled at 6.5. After the addition was completed, the reaction was continued for 60 minutes, aged at 60°C for 4 hours, and the cobalt carbonate precursor was suction filtered or pressed. filter, and wash the precipitate by suction filtration or pressure filtration, spin dry after washing, dry at 110°C for 10 hours, and finally calcinate at 500°C for 2 hours. The finally obtained cobalt tetroxide powder, under the S4800 type field emission sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com