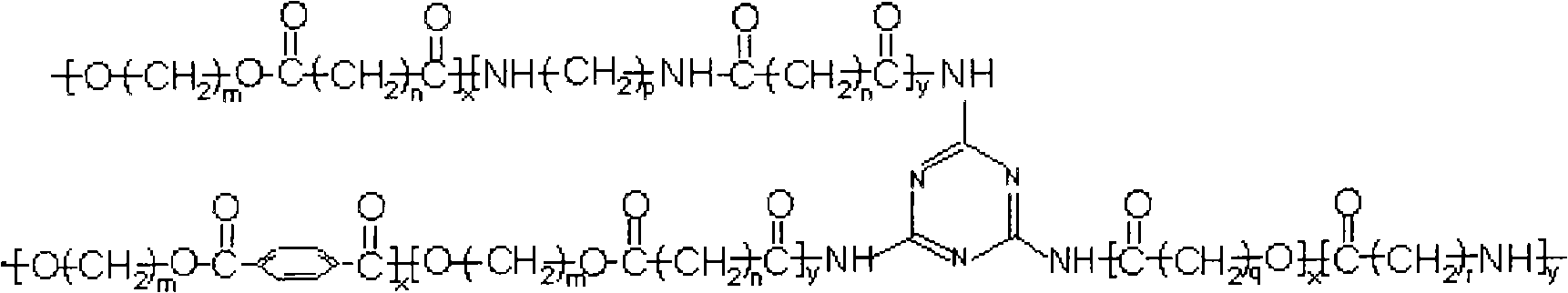

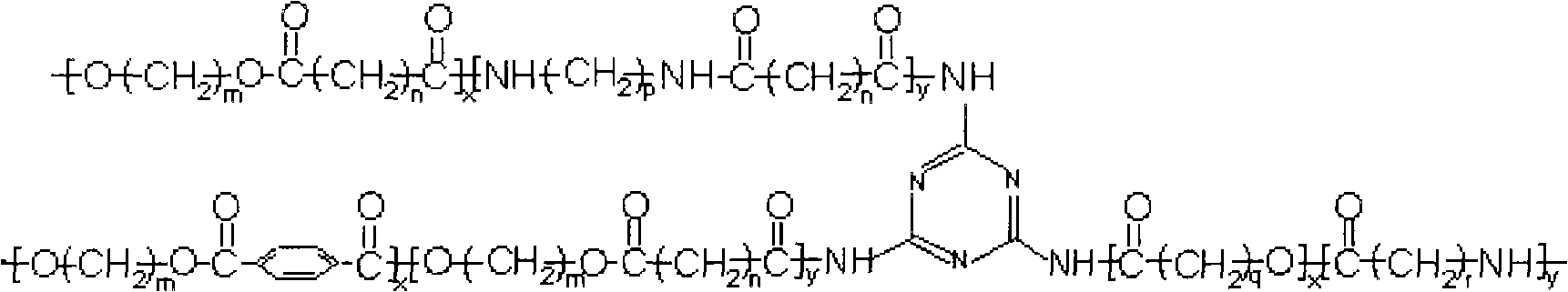

Appropriately crosslinked biodegradable polyester-amides random block copolymer and synthesizing method thereof

A technology of biodegradation and polyester amide, which is applied in the field of polyester amide polymer materials, can solve the problems of insufficient biodegradation performance of polyester amide, insufficient degradation performance, and toxicity of raw materials, etc., and achieve good biodegradation performance and degradation performance Good, simple method and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, add 174g dimethyl adipate, 194g dimethyl terephthalate, 120g 1,4-butanediol, 40.7g ethanolamine, 340mg tetrabutyl titanate, 5g antioxidant 1010 into the nitrogen inlet , a stirrer, and a four-necked flask with a condenser, feed nitrogen gas, raise the temperature to 140-160° C., and stir for 1-3 hours to react. Then slowly reduce the pressure, and gradually increase the temperature to 220-260°C, control the vacuum degree within 200Pa, and react for 3-6 hours. Then add 8.4 g of melamine into the reaction system, maintain the reaction temperature at 120-200° C., and react for another 0.5-2 hours. The obtained product is white, the molecular weight Mw measured by GPC method is 91,500, and the molecular weight distribution is 6.57.

Embodiment 2

[0034] At room temperature, add 146g of adipic acid, 166g of terephthalic acid, 153g of 1,4-butanediol, 18.3g of ethanolamine, 340mg of tetrabutyl titanate, and 5g of antioxidant 1010 into a tank equipped with a nitrogen inlet, a stirrer, and a condenser in sequence. In the four-necked flask, nitrogen gas was introduced, the temperature was raised to 140-160°C, and the reaction was stirred for 1-3 hours. Then slowly reduce the pressure, and gradually increase the temperature to 220-260°C, control the vacuum degree within 200Pa, and react for 3-6 hours. Then add 8.4 g of melamine into the reaction system, maintain the reaction temperature at 120-200° C., and react for another 0.5-2 hours. The obtained product is light yellow, the molecular weight Mw determined by GPC method is 80,300, and the molecular weight distribution is 5.16.

Embodiment 3

[0036] At room temperature, 146g dimethyl succinate, 194g dimethyl terephthalate, 90g 1,4-butanediol, 63.6g diethylene glycol, 23.2g hexamethylenediamine, 340mg tetrabutyl titanate, 5g anti Oxygen agent 1010 is sequentially added to a four-neck flask equipped with a nitrogen inlet, a stirrer, and a condenser, nitrogen is passed through, the temperature is raised to 140-160°C, and the reaction is stirred for 1-3 hours. Then slowly reduce the pressure, and gradually increase the temperature to 220-260°C, control the vacuum degree within 200Pa, and react for 3-6 hours. Then add 16.8 g of melamine into the reaction system, maintain the reaction temperature at 120-200° C., and react for another 0.5-2 hours. The obtained product is white, the molecular weight Mw determined by GPC method is 137,900, and the molecular weight distribution is 6.21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com