Method for extracting multi-metallic element from high chromium vanadium titanium octahedral iron ore

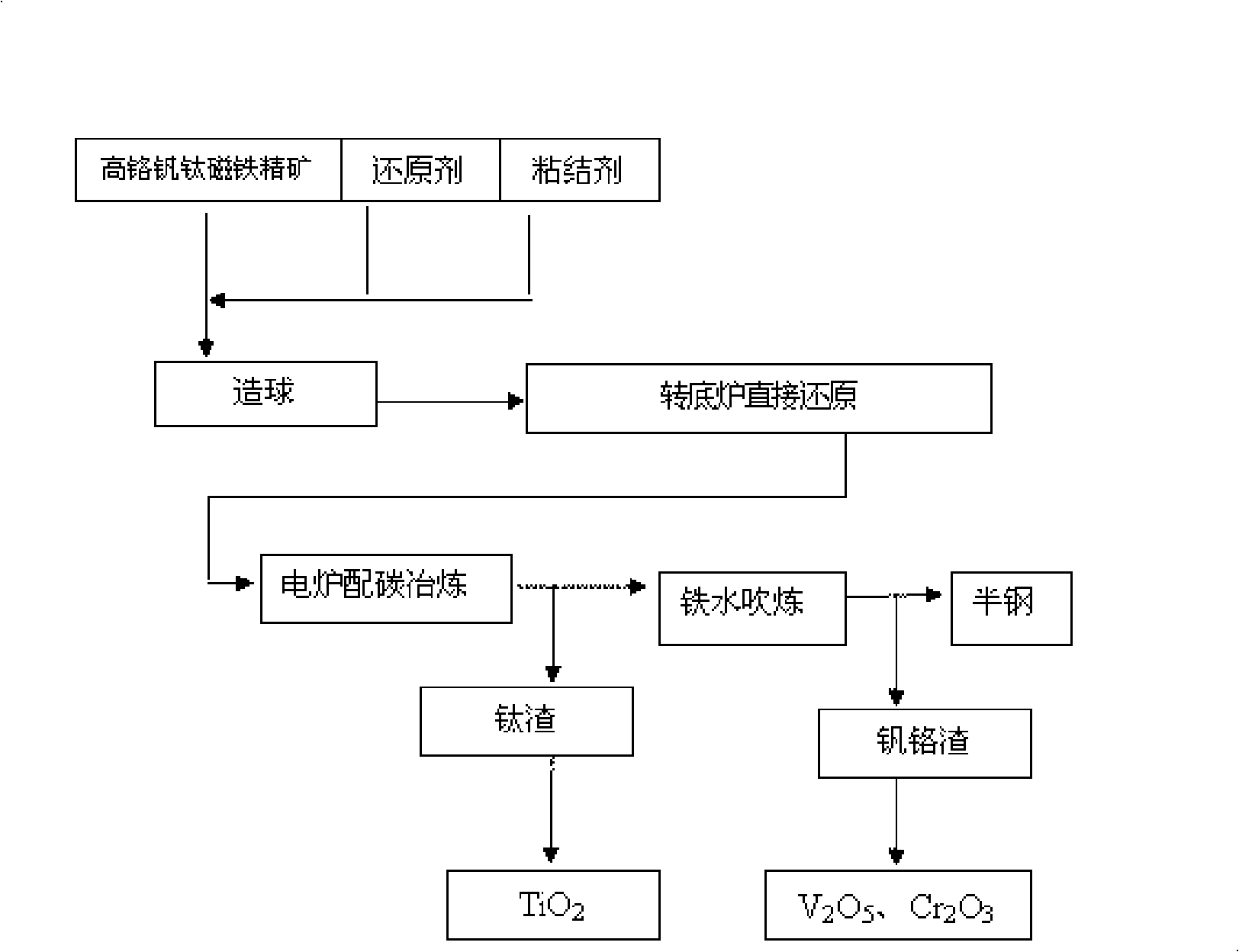

A technology for vanadium titanomagnetite and metal elements, applied in the field of metal smelting, can solve the problems of inability to recover titanium resources, waste of resources, complicated procedures, etc., and achieve the effects of reducing water consumption, being difficult to break and rolling, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] High chromium vanadium titanium magnetite concentrate (main components: TFe: 54.01%, FeO: 27.02%, V 2 o 5 : 0.56%, Cr 2 o 3 : 1.58%, TiO 2 : 12.18%) after mixing the ingredients, press the elliptical inner carbon pellets with a growth diameter of 25mm, dry them at 120°C and send them into the rotary hearth furnace. %O 2 =1.0, %CO / %CO 2 =0.9, the metallization rate of pellets after reduction reaches 91.5%, the residual carbon content is 3.7%, and the production capacity reaches 100kg / (m 2 .h), N 2 Gas protection of the metallized pellets discharged from the rotary hearth furnace; then put the metallized pellets at a temperature of 300°C into the electric furnace and add coal powder with a total weight of 8% of the pellets, and smelt at 1560°C for a certain period of time Add coal powder with 10% of the total weight of the pellets, the total smelting time is 140min, and TiO is separated 2 Titanium slag with a content of 49%; then the molten iron obtained after sep...

Embodiment 2

[0033] Mix high-chromium vanadium-titanium magnetite concentrate (the main components are the same as in Example 1) and press it into elliptical carbon pellets with a long diameter of 38mm. Dry at 180°C and send them to a rotary hearth furnace for reduction at 1400°C. 50min, material layer thickness 160mm, %O in the furnace during the reduction process 2 =1.2, %CO / %CO 2 =1.8, the metallization rate of pellets after reduction reaches 92.1%, the residual carbon content is 3.1%, and the production capacity reaches 125kg / (m 2 .h); then the metallized pellets are directly hot-charged into an electric furnace and coke powder with a total weight of 15% of the pellets is added, smelted at 1600°C for 100min, and TiO is separated to obtain 2 Titanium slag with a content of 51%, after blowing the molten iron obtained from smelting, V 2 o 5 =6.1%, Cr 2 o 3 =16.3% vanadium-chromium slag and semi-steel; to this step, the corresponding Fe, TiO in each semi-product 2 , V 2 o 5 、Cr 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com