Method using selective active film for purifying gas and equipment thereof

A gas purification and selective technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of complex structure of purification equipment, narrow scope of application, strict process requirements, etc. The effect of saving solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Flue gas desulfurization, denitrification and dust removal

[0019] First prepare the selective active film forming liquid, select 30 parts by weight of water as solvent, use 10 parts by weight of hydrolyzed rosin as surfactant, and use 20 parts by weight of NH 4 HCO 3 as an absorbent. Mix them evenly and inject them into the selective active membrane generator.

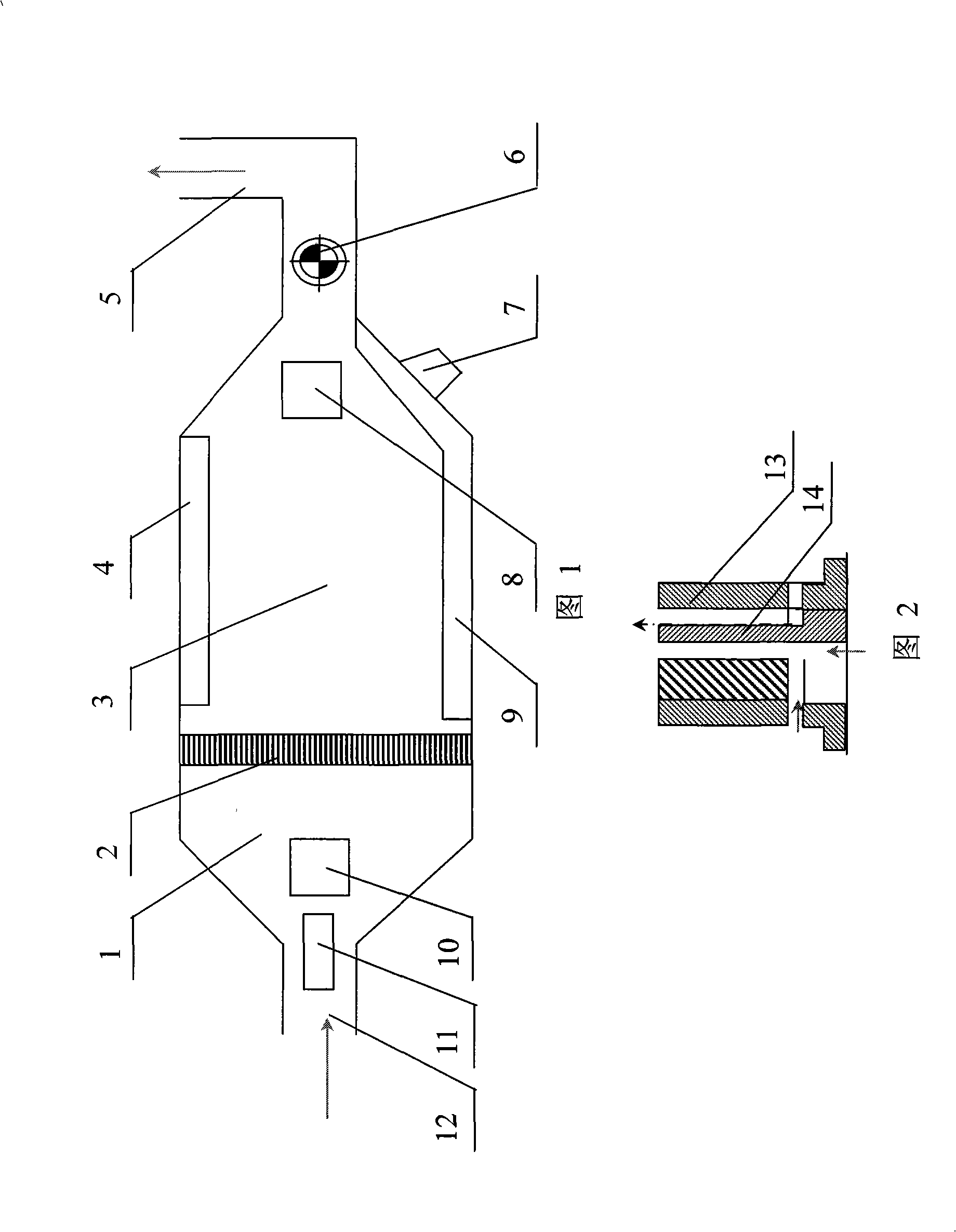

[0020] As shown in Fig. 1, the selective active membrane reactor includes a volume expansion chamber 1, a gas purification absorption chamber 3, and a selective active membrane generator integrated plate 2 arranged between the volume expansion chamber 1 and the gas purification absorption chamber 3. The volume expansion chamber 1 is directly connected to the gas inlet 12 , and the gas purification absorption chamber 3 is between the selective active membrane generator integrated plate 2 and the gas outlet 5 . An observation window 4 is provided on the top of the gas purification absorption chamber...

Embodiment 2

[0034] Embodiment 2 natural gas or water gas dehydrogen sulfide

[0035] Firstly, a selectively active membrane forming solution was prepared, using 50 parts by weight of water as a solvent, 25 parts by weight of polyethylene glycol dimethyl ether as a surfactant, and 40 parts by weight of water as an absorbent. They are uniformly mixed and injected into the selectively active membrane generator.

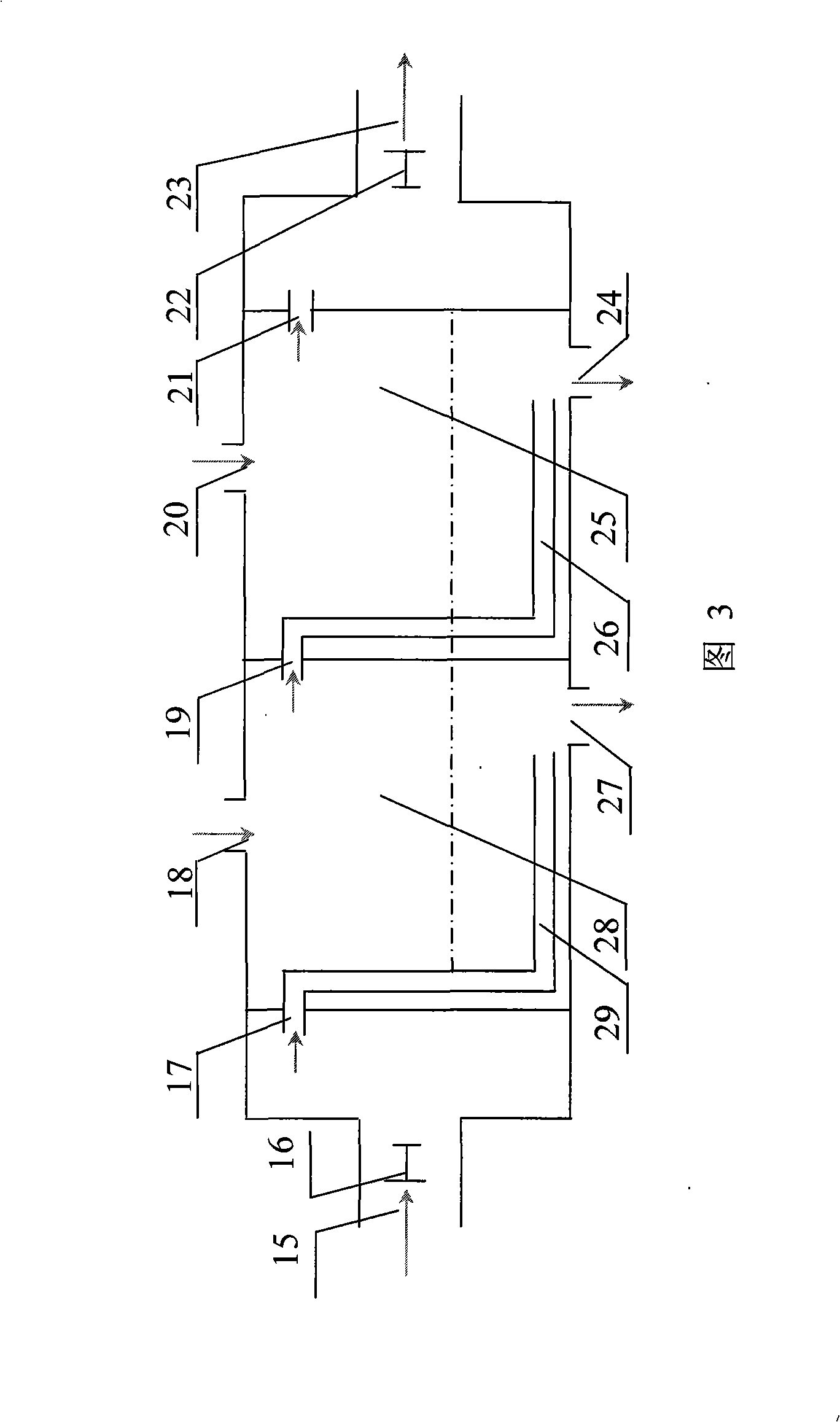

[0036] As shown in Figure 3, the selective active membrane reactor includes a gas purification absorption chamber and a selective active membrane generator located in the gas purification absorption chamber. The gas purification absorption chamber includes a gas purification absorption chamber I 28 and a gas purification absorption chamber II 25 , and the selective active film generator includes an active film generator I 29 and an active film generator II 26 . The gas purification absorption chamber I 28 is connected to the reactor inlet 15, and a gas source pipeline 17 is arrange...

Embodiment 3

[0042] The control of embodiment 3 automobile tail gas

[0043] The selective active membrane forming liquid used in the present embodiment selects 45 parts by weight of water as a solvent, and the surfactant includes 15 parts by weight of sodium dodecylbenzenesulfonate, 10 parts by weight of rosin potassium soap and 5 parts by weight of fatty acid Magnesium, with 20 parts by weight liquid paraffin, 10 parts by weight NH 4 HCO 3 and 6 parts by weight K 2 CO 3 as an absorbent. Stir with air at room temperature to form a water-in-oil (W / O) selective active membrane forming fluid.

[0044] In this implementation, the selective active membrane reactor and regenerative membrane reactor described in the second embodiment are selected. The specific operation is as follows:

[0045] As shown in Fig. 3, when the exhaust gas of the automobile enters the selective active membrane reactor through the air inlet 15 and promotes the flow rate of the balance gas pump 16. The selective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com