Preparation of doped titanium dioxide nano-tube

A technology of titanium dioxide and titanium dioxide lattice, applied in the field of nanomaterials, can solve the problems of difficult access and unfavorable doping ions, and achieve the effects of easy operation, controllable doping amount and good crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

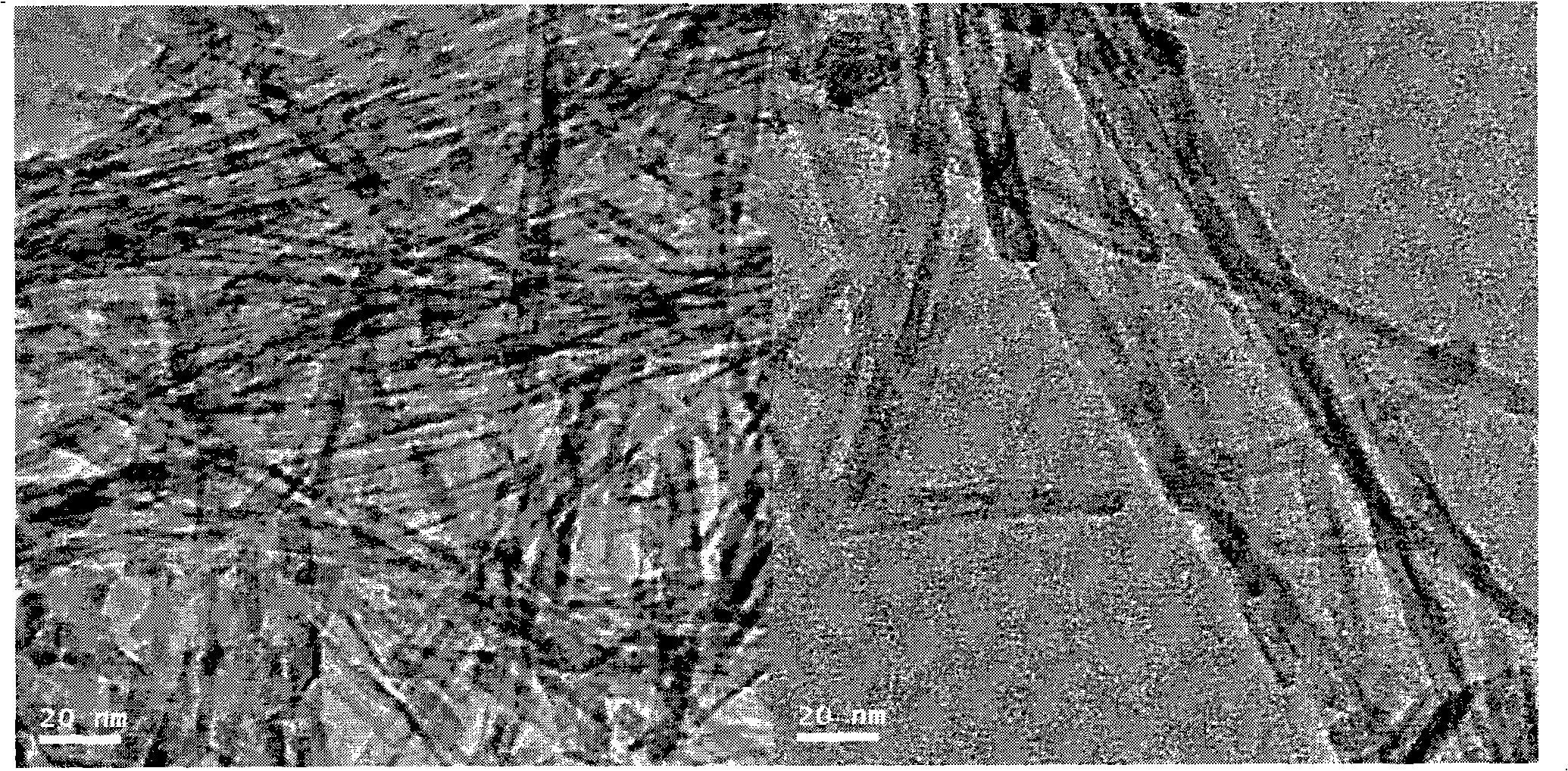

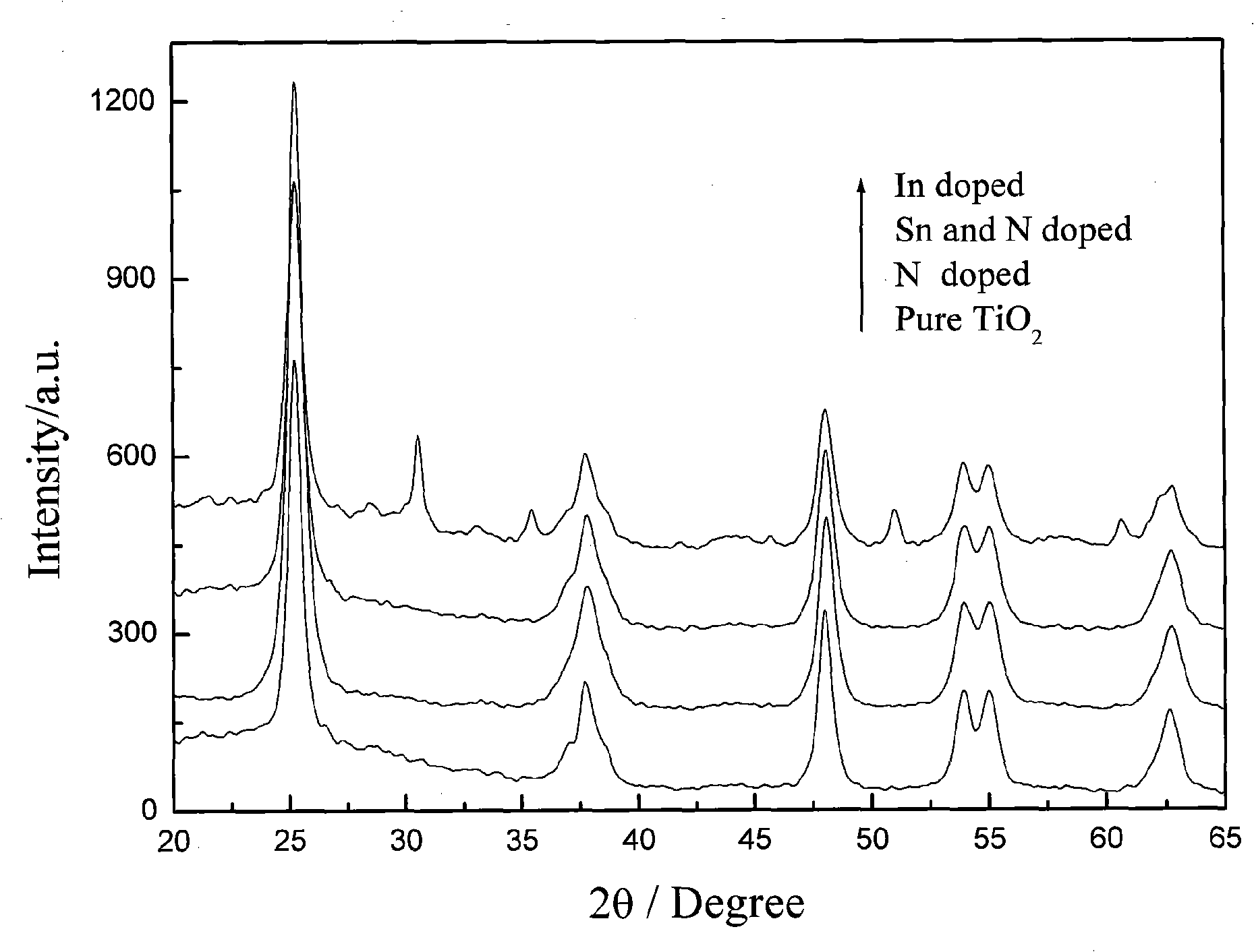

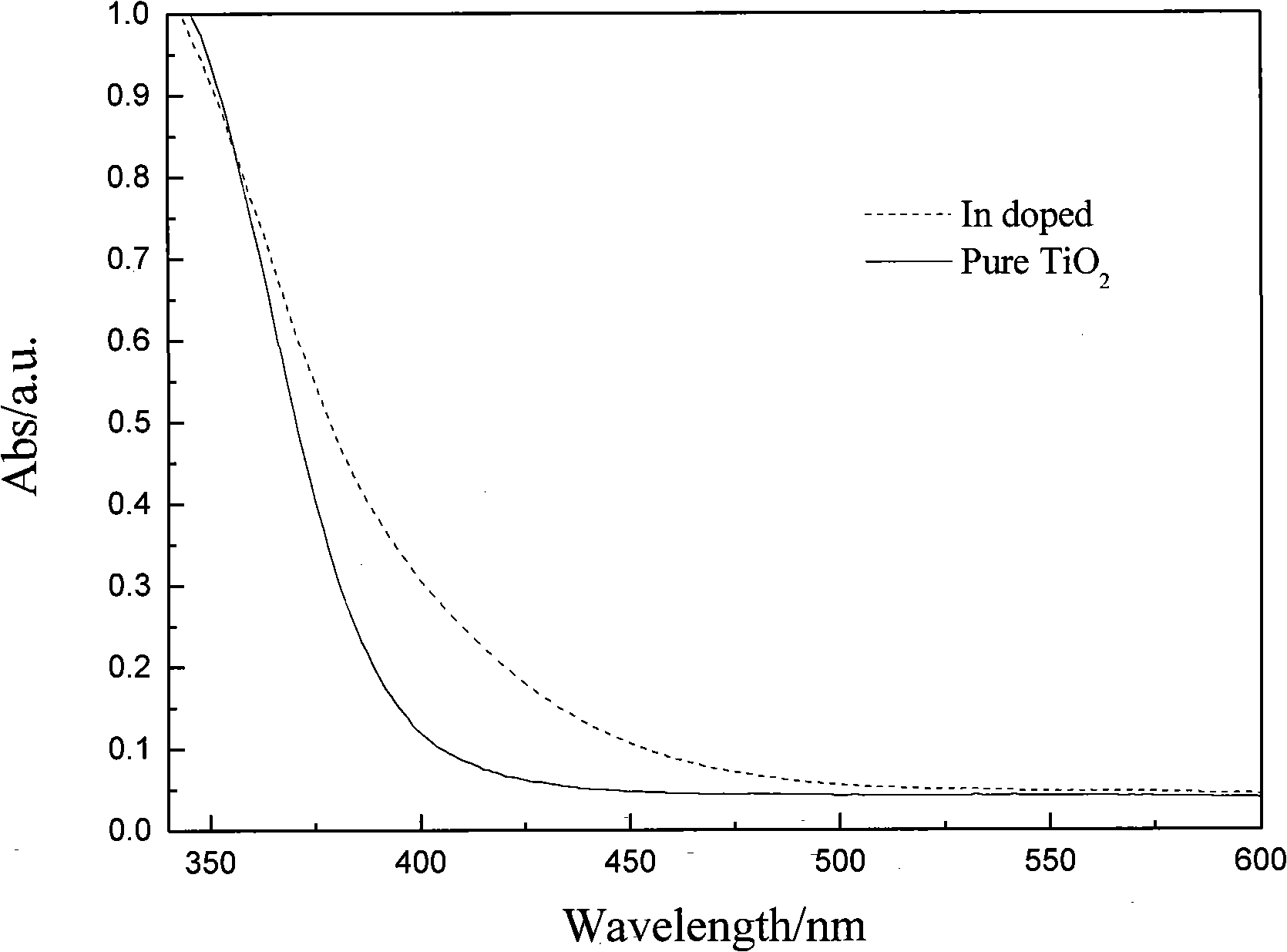

[0014] Example 1: In doped TiO 2 nanotube

[0015] 1. Preparation of In-doped TiO by sol-gel method 2 Nano powder. Take 12ml of tetrabutyl titanate and slowly drop it into a beaker mixed with 40ml of absolute ethanol, 2ml of deionized water and 1ml of hydrochloric acid. After stirring for half an hour, add 0.2ml of indium trichloride and drop it into the beaker; a transparent sol is obtained and left to stand. After a period of time, after gelling, it is dried at 100°C for 10-12 hours to obtain a dry gel; after grinding, it is calcined at 450°C for 2.5 hours and then taken out to obtain In-doped TiO 2 Nano powder.

[0016] 2. Doping 0.4g In with TiO 2 The nano powder was mixed with 18ml of 10mol / L NaOH solution and added to the reaction kettle for stirring. After half an hour, the autoclave was placed in an oven and heated to 110°C for 20 hours.

[0017] 3. Take out the reacted autoclave, after it cools naturally, centrifuge, pour off the supernatant, wash the precipitate with dei...

Embodiment 2

[0019] Example 2: N-doped TiO 2 nanotube

[0020] 1. Use TiCl 4 Preparation of N-doped TiO by hydrolysis 2 Nano powder. 25% ammonia water is added dropwise to 200mL under vigorous stirring, the concentration is about 0.1molL -1 In the titanium tetrachloride aqueous solution, a white precipitate was immediately produced in the system, and the addition of ammonia was stopped when the pH value of the system reached 5.5. Then it was allowed to stand and age for 24 hours, filtered, and the resulting precipitate was dried at 70°C, ground into powder, and sintered at 400°C for 4 hours. N-doped TiO 2 Nano powder

[0021] 2. Doping 0.4g N with TiO 2 The nano powder was mixed with 18ml of 10mol / L NaOH solution and added to the reaction kettle for stirring. After half an hour, the autoclave was placed in an oven and heated to 110°C for 20 hours.

[0022] 3. Take out the reacted autoclave, after it cools naturally, centrifuge, pour off the supernatant, wash the precipitate with deionized wate...

Embodiment 3

[0024] Example 3: N and Sn double-doped TiO 2 nanotube

[0025] 1. Preparation of N and Sn double-doped TiO by sol-gel method 2 Nano powder. Take 12ml of tetrabutyl titanate slowly drop into a beaker mixed with 40ml of absolute ethanol, 2ml of deionized water and 1ml of hydrochloric acid. After stirring for half an hour, add 0.2ml of tin tetrachloride, and after another half an hour, add 3ml of ammonia to obtain Transparent sol, let stand for a period of time, after gel, dry at 100℃ for 10-12 hours to obtain dry gel; after grinding, calcined at 450℃ for 2.5 hours, take it out to obtain N and Sn double-doped TiO 2 Nano powder.

[0026] 2. Double-doped TiO with 0.4g N and Sn 2 The nano powder was mixed with 18ml of 10mol / L NaOH solution and added to the reaction kettle for stirring. After half an hour, the autoclave was placed in an oven and heated to 110°C for 20 hours.

[0027] 3. Take out the reacted autoclave, after it cools naturally, centrifuge, pour off the supernatant, wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com