Preparation of icaritin

A technology of icariin and icariin, which is applied in the field of extraction of the active ingredient icariin, can solve the problems of no use value, poor deglycolysis efficiency, low product yield, etc. Easy handling, easy operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Enzymatic hydrolysis of icariin Add 100g of icariin to 5000ml of 20% ethanol, stir to dissolve, add 10g of β-glucosidase, and hydrolyze at 60°C for 20 hours.

[0033] 2. Post-treatment of the reaction solution: centrifuge the reaction solution and discard the supernatant. The precipitate was dissolved with 2500ml of acetone, the solution was centrifuged, the supernatant was taken out, filtered, the insoluble matter was discarded, and the supernatant was evaporated to dryness.

[0034] 3. Preparation of pure icariin (glycogen):

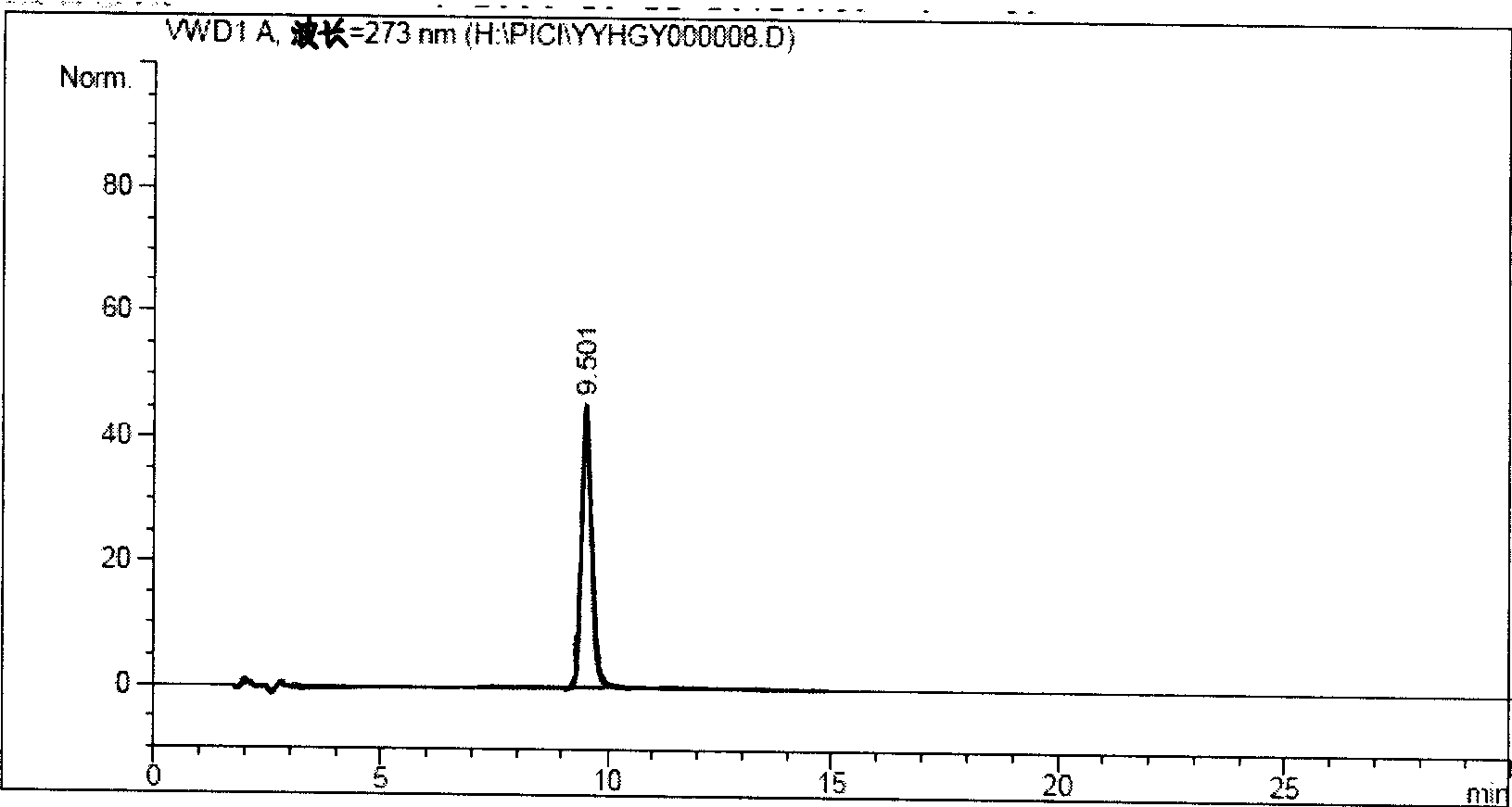

[0035] Add acetone-water (1:1) 1500ml to recrystallize, let stand, crystallize, filter and dry to obtain 29g of pure icariin. The purity is over 98% as detected by HPLC. (Such as figure 1 ) HPLC condition is acetonitrile-1% glacial acetic acid aqueous solution 70:30, detection wavelength 273nm. Melting point: higher than 250°C.

[0036] Overall yield: 53.3%.

Embodiment 2

[0038] 1. Enzymatic hydrolysis of icariin Add 100g of icariin to 5000ml of 20% ethanol, stir to dissolve, add 100g of β-glucosidase, and hydrolyze at 40°C for 30 hours.

[0039] 2. Post-treatment of the reaction solution: centrifuge the reaction solution and discard the supernatant. The precipitate was dissolved with 2500ml of acetone, the solution was centrifuged, the supernatant was taken out, filtered, the insoluble matter was discarded, and the supernatant was evaporated to 25ml per gram (relative to icariin).

[0040]3 Preparation of pure icariin:

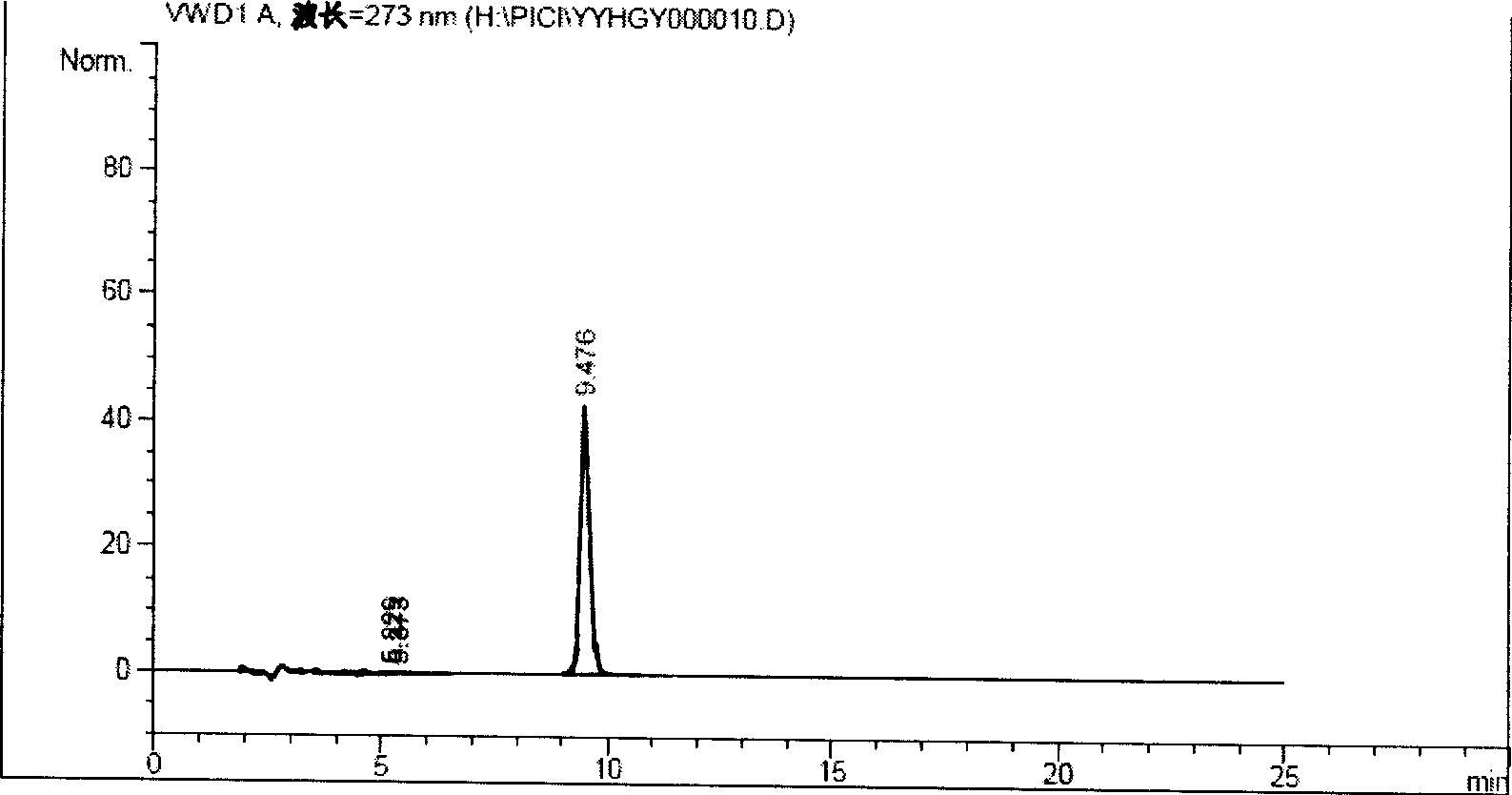

[0041] Take the concentrated supernatant, add an equal amount of water to recrystallize, place, crystallize, filter, and dry to obtain 30.2 g of pure icariin. The purity is over 98% as detected by HPLC. (Such as figure 2 ) HPLC condition is acetonitrile-1% glacial acetic acid aqueous solution 70:30, detection wavelength 273nm.

[0042] The total yield is 55.5%.

[0043] Because the solvent acetone is used in the aftertre...

Embodiment 3

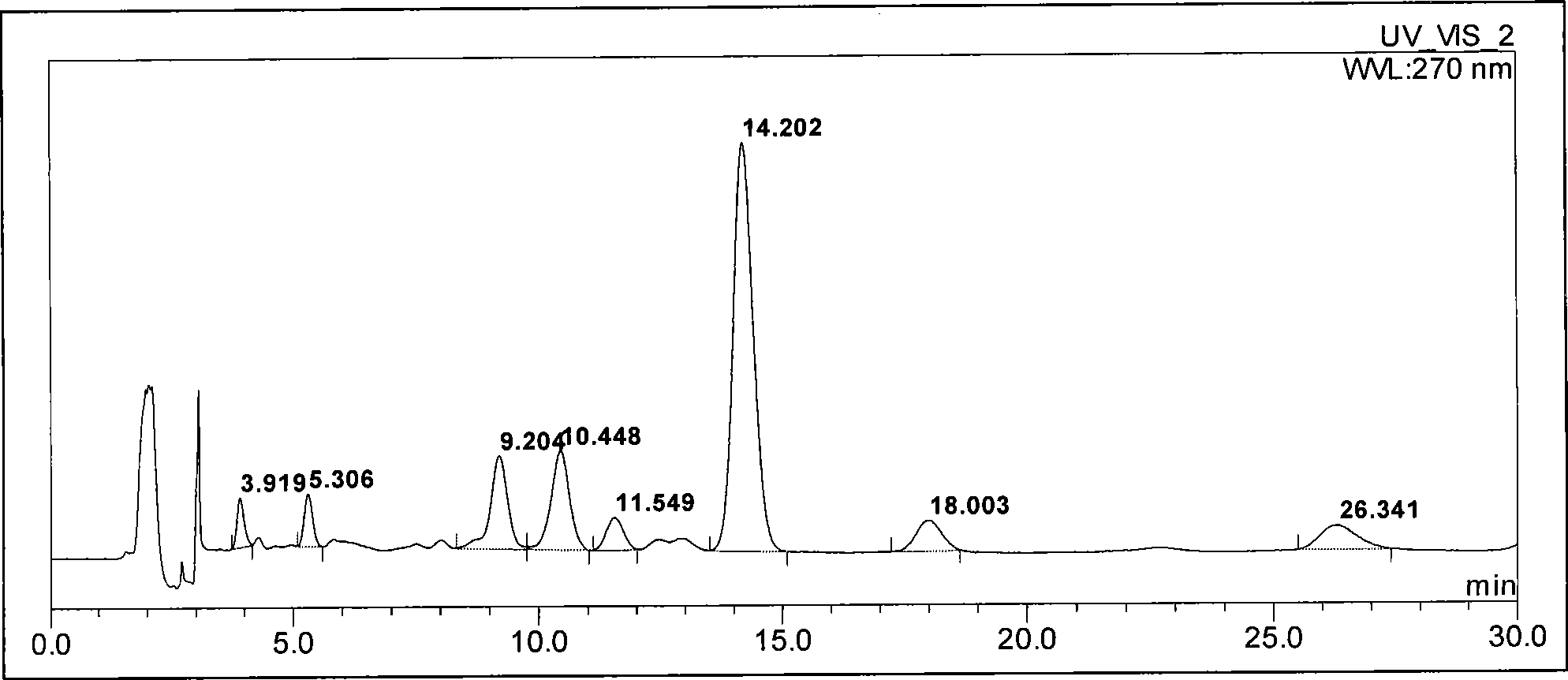

[0045] 3.1 Extraction of total flavonoids from Epimedium

[0046] 3.1.1 Pulverization: Pulverize 10,000 g of dried epimedium and put it into an extraction tank.

[0047] 3.1.2 Extraction: Add 16 times the amount of water to decoct 3 times, 2 hours for the first time, and 1.5 hours for each subsequent time. The three extracts were combined, filtered, and concentrated under reduced pressure to a solution of 0.2 g raw medicinal material / ml.

[0048] 3.1.3 Resin purification: the extract is absorbed by the pre-treated D101 macroporous resin column for total flavonoids (the amount of resin used is about 1.5 times that of medicinal materials.). The flow rate of the extract on the column was 5 column volumes / h. After adsorption, first wash with water until the water eluent is light yellow, about 4 column volumes, and then use 30% ethanol, about 4 column volumes, 50% ethanol, about 4 column volumes, and 90% ethanol after treatment, Wash with water and set aside.

[0049] 3.1.4 Con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com