Boron-magnesium-calcium powder E glass formula

A technology of boron-magnesium-calcium powder and boron-magnesium-calcium, which is applied in the production formula field of E glass, can solve the problems of increased production cost, labor consumption, and increased production cost of the flue gas treatment process, so as to improve quality, improve quality, The effect of reducing the fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

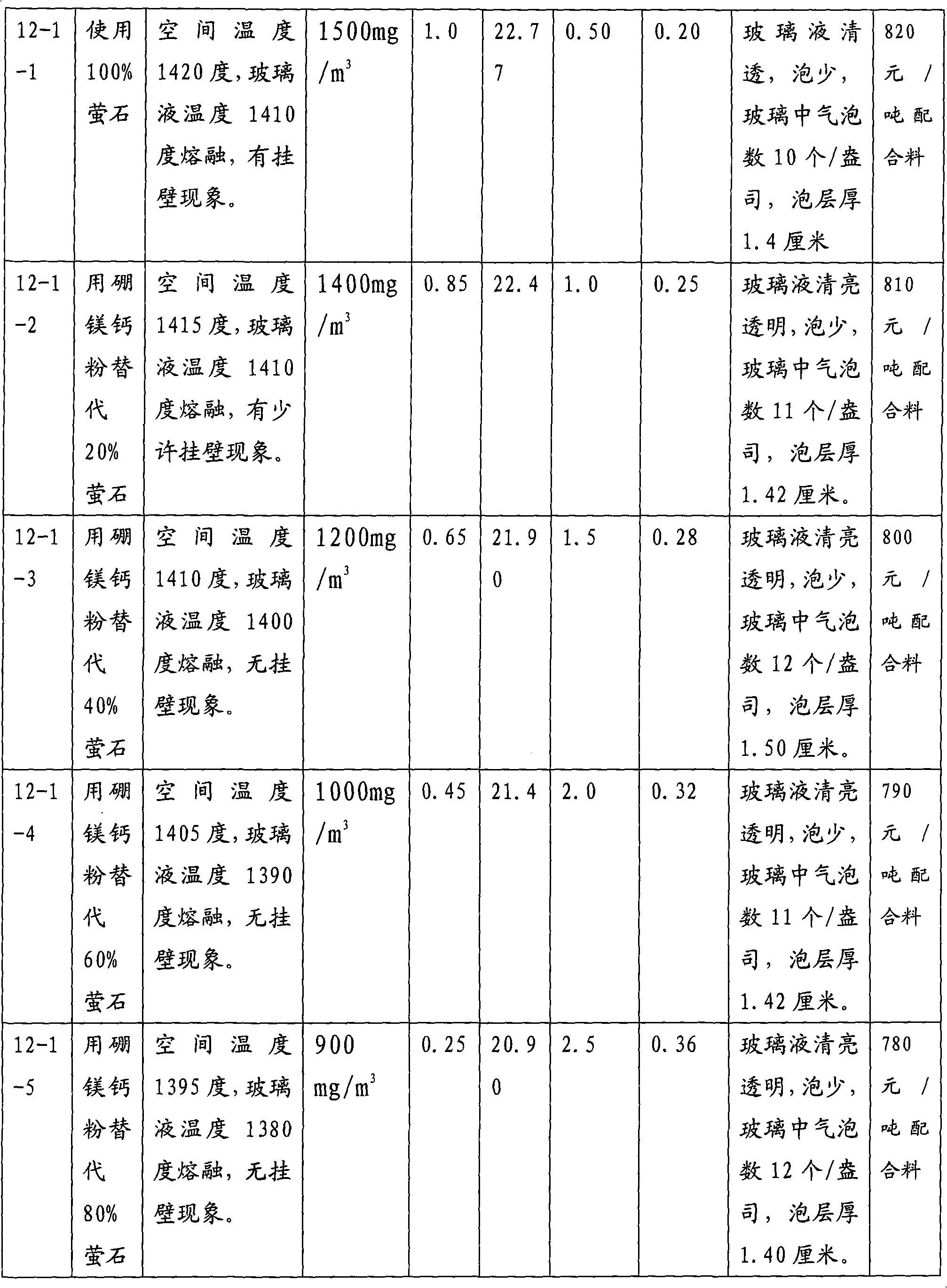

Embodiment 1

[0016] The raw material composition of E glass, each component by weight includes: silicon dioxide 53.9, aluminum oxide 13.9, boron trioxide 6.5, calcium oxide 22.77, magnesium oxide 0.50, iron oxide 0.40, titanium oxide 0.42, fluorine 1.0, Sodium oxide + potassium oxide 0.50.

[0017] Among them, the fluorine element is added in the form of fluorite, and fluorite is completely used as a co-solvent.

Embodiment 2

[0019] The raw material composition of E glass includes, in parts by weight, silicon dioxide 53.95, aluminum oxide 13.85, boron trioxide 6.55, calcium oxide 22.4, magnesium oxide 1.0, iron oxide 0.35, titanium oxide 0.4, fluorine 0.85, Sodium oxide + potassium oxide 0.53.

[0020] Among them, boron magnesium calcium powder is used to replace 20% of the fluorite consumption.

Embodiment 3

[0022] The composition of the raw materials of E glass includes, in parts by weight, silicon dioxide 53.85, aluminum oxide 13.95, boron trioxide 6.50, calcium oxide 21.86, magnesium oxide 1.5, iron oxide 0.42, titanium oxide 0.38, fluorine 0.65, Sodium oxide + potassium oxide 0.53.

[0023] Among them, boron magnesium calcium powder is used to replace 40% of the fluorite consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com