Water-soluble colorful coating and preparation thereof

A technology of water-based colorful paints and water-based paints, applied in the direction of multi-color effect paints, coatings, latex paints, etc., can solve the problems of troublesome use, storage and transportation, anesthesia in the central system, and difficult to achieve VOC, etc., to achieve storage and The effect of convenient transportation, low cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

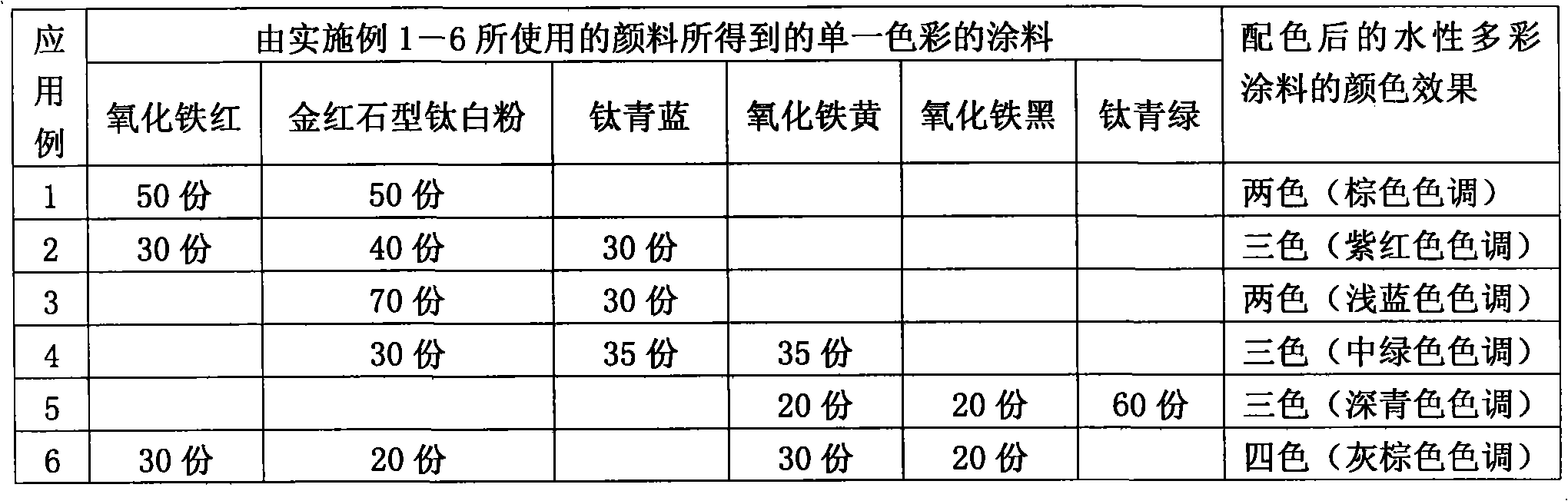

Examples

Embodiment 1

[0025] A) prepare color-taking pellets, take alcohol-soluble thermoplastic solid acrylic resin by weight, i.e. 10 parts of alcohol-soluble resin, 78 parts of n-butanol, 10 parts of polyanion cellulose and pigment such as iron oxide red with a viscosity of 40000mpa s 2 parts, with one part of the 78 parts of n-butanols taken by weighing and 10 parts of alcohol-soluble resins, to obtain the resin syrup, with another part of n-butanols in the 78 parts of n-butanols taken by weighing Alcohol and 10 parts of polyanionic cellulose are reconciled into cellulose pulp, and then the last part of n-butanol in the 78 parts of n-butanol that has been weighed is mixed with 2 parts of pigments, namely iron oxide red, into pigment paste, and the pigment paste Grinding with a grinder until the fineness is >500 mesh, combining the resin pulp, cellulose pulp and pigment pulp to obtain colored pellets for use;

[0026] B) Take protective colloid material, take by weight 0.5 parts of cationic guar...

Embodiment 2

[0030] A) Prepare color-taking pellets, take by weight alcohol-soluble thermoplastic solid acrylic resin, namely 20 parts of alcohol-soluble resin, 74 parts of n-butanol, 7.5 parts of polyanionic cellulose and 3.5 parts of rutile titanium dioxide with a viscosity of 40000mpa s. part, with one of the 74 parts of n-butanols that have been weighed to blend with the 15 parts of alcohol-soluble resins to obtain resin syrup, with another part of n-butanols in the 74 parts of n-butanols that have been weighed Blend into cellulose pulp with 7.5 parts of polyanionic cellulose, then use the last part of n-butanol in the 74 parts of n-butanol and 3.5 parts of pigments to blend into pigment slurry, and grind the pigment slurry with a grinder until Fineness > 500 mesh, the resin pulp, cellulose pulp and pigment pulp are combined to obtain colored pellets for use;

[0031] B) Prepare protective colloid material, take by weight 0.75 parts of cationic guar gum, 42.25 parts of cationic water, ...

Embodiment 3

[0035] A) prepare the color-taking pellet, take by weight alcohol-soluble thermoplastic solid acrylic resin, namely 20 parts of alcohol-soluble resin, 70 parts of n-butanol, 5 parts of polyanionic cellulose and 5 parts of titanium blue blue with a viscosity of 40000mpa s , use one of the 70 parts of n-butanol to be weighed to blend with the 20 parts of alcohol-soluble resin to obtain the resin slurry, and use another part of the 70 parts of n-butanol to be weighed with the 5 parts of polyanionic cellulose are blended into cellulose pulp, then the last part of n-butanol in the 70 parts of n-butanol and 5 parts of pigments are blended into pigment paste, and the pigment paste is ground to fine degree>500 mesh, the resin pulp, cellulose pulp and pigment pulp are combined to obtain colored pellets for use;

[0036] B) Prepare the protective colloid material, take by weight 1 part of cationic guar gum, 64 parts of cationic water, 30 parts of cationic acrylic emulsion and 5 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com