Nano-hydroxyapatite glycerin cement, preparation method and application in toothpaste thereof

A technology of nano-hydroxyapatite and glycerin, which is applied in the fields of chemical instruments and methods, dentistry, phosphorus compounds, etc., can solve the problems of increasing product cost, complex preparation and dispersion technology, and affecting popularization and application, and achieves high utilization rate and low cost of raw materials. Inexpensive and easy to obtain, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

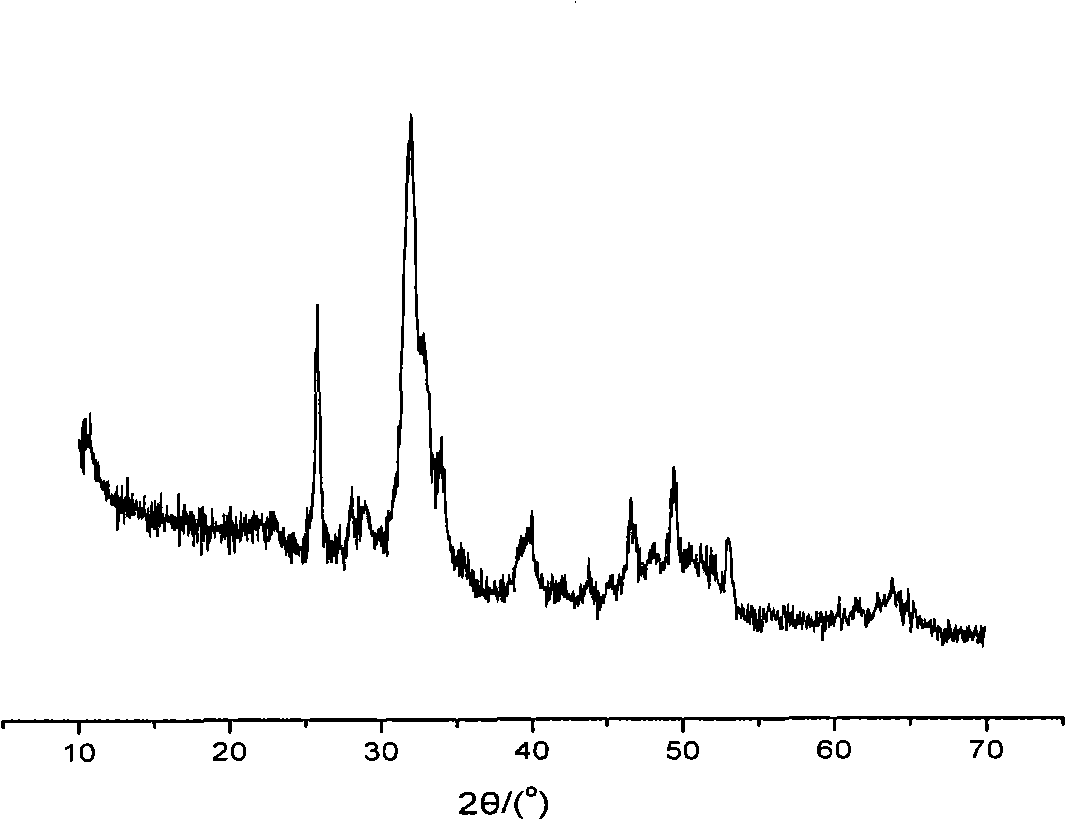

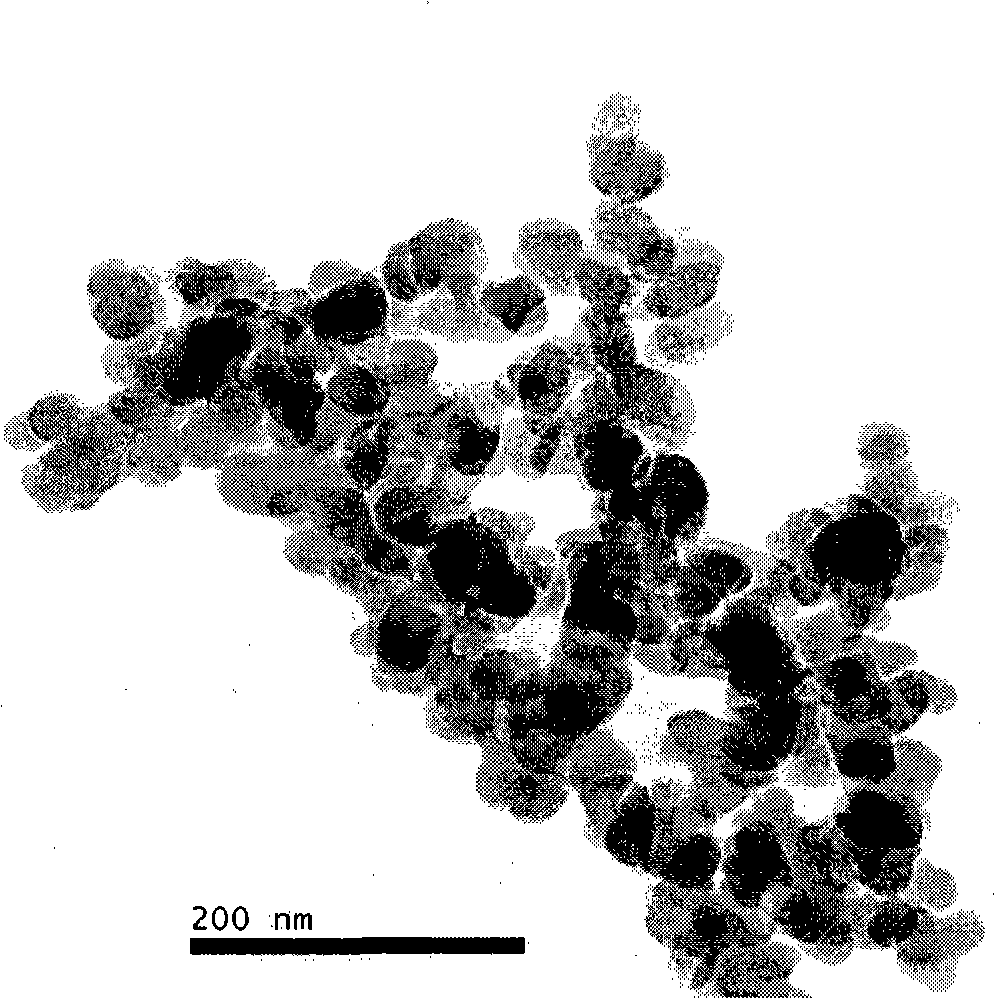

Image

Examples

Embodiment 1

[0033]In the first step, 0.9 kg of calcium hydroxide is pulverized and passed through a 300-mesh sieve to obtain calcium hydroxide powder; a mass ratio of 0.6: 1 is mixed with ethanol and glycerin to make 12 kg of ethanol-glycerin mixture; the powder Add to ethanol-glycerin mixture, stir evenly at room temperature to make component A;

[0034] In the second step, add the concentrated phosphoric acid solution into ethanol, stir evenly to make component B, wherein the mass ratio of phosphoric acid to ethanol is 1:10;

[0035] The third step is to put component A into a 25L reaction kettle with a reflux device, stir and heat up to a slight boil, and after 30 minutes, add component B into the reaction kettle at a speed of 2-20ml / min first and then slowly, and wait for the reaction Stop adding when the pH value of the mixed solution in the still is stable at 8.5, continue to react for 4 hours, and keep a little boiling and stirring in the reaction process;

[0036] In the fourth s...

Embodiment 2

[0041] The first step, after mixing calcium hydroxide 0.85kg and strontium hydroxide octahydrate 0.15kg, pulverize, cross 300 mesh sieves, obtain the powder of calcium hydroxide and strontium hydroxide octahydrate mixture; Be 1: 1 by mass ratio Proportionally mix ethanol and glycerin to make 12kg of ethanol-glycerin mixture; add the powder into the ethanol-glycerin mixture, stir evenly at room temperature to make component A;

[0042] In the second step, the concentrated phosphoric acid solution is added to ethanol, and stirred evenly to make component B, wherein the mass ratio of phosphoric acid to ethanol is 1:5;

[0043] The third step is to put component A into a 25L reaction kettle with a reflux device, stir and heat up to a slight boil, and after 30 minutes, add component B into the reaction kettle at 2-10ml / min first and then slowly, and wait for the reaction Stop adding when the pH value of the mixed solution in the still is stable at 8.0, continue to react for 4 hours...

Embodiment 3

[0047] In the first step, 0.7 kg of calcium oxide is pulverized and passed through a 300-mesh sieve to obtain calcium oxide powder; the mass ratio is 1:1 by mixing ethanol and glycerin to make 12 kg of ethanol-glycerin mixture; adding the powder to ethanol In the glycerin mixture, stir evenly at room temperature to make component A;

[0048] In the second step, glycerin and ethanol are mixed in a ratio of 0.5:1 by mass to obtain a glycerol-ethanol mixture; the concentrated phosphoric acid solution is added to glycerol-ethanol, and stirred evenly to make component B, wherein the mass of phosphoric acid and glycerol-ethanol mixture The ratio is 1:10;

[0049] The third step is to put component A into a 25L reaction kettle with a reflux device, stir and heat up to a slight boil, and after 30 minutes, add component B into the reaction kettle at 2-10ml / min first and then slowly, and wait for the reaction Stop adding when the pH value of the mixed solution in the still is stable at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com