Bi-component aqueous epoxy coating for aluminum alloy material and composite material

A water-based epoxy coating, aluminum alloy material technology, applied in epoxy resin coatings, coatings, latex paints and other directions, can solve problems such as failure to obtain satisfaction, and achieve better compatibility, uniform curing, and freezing point drop. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 prepares the aqueous amine-epoxy adduct of amine termination

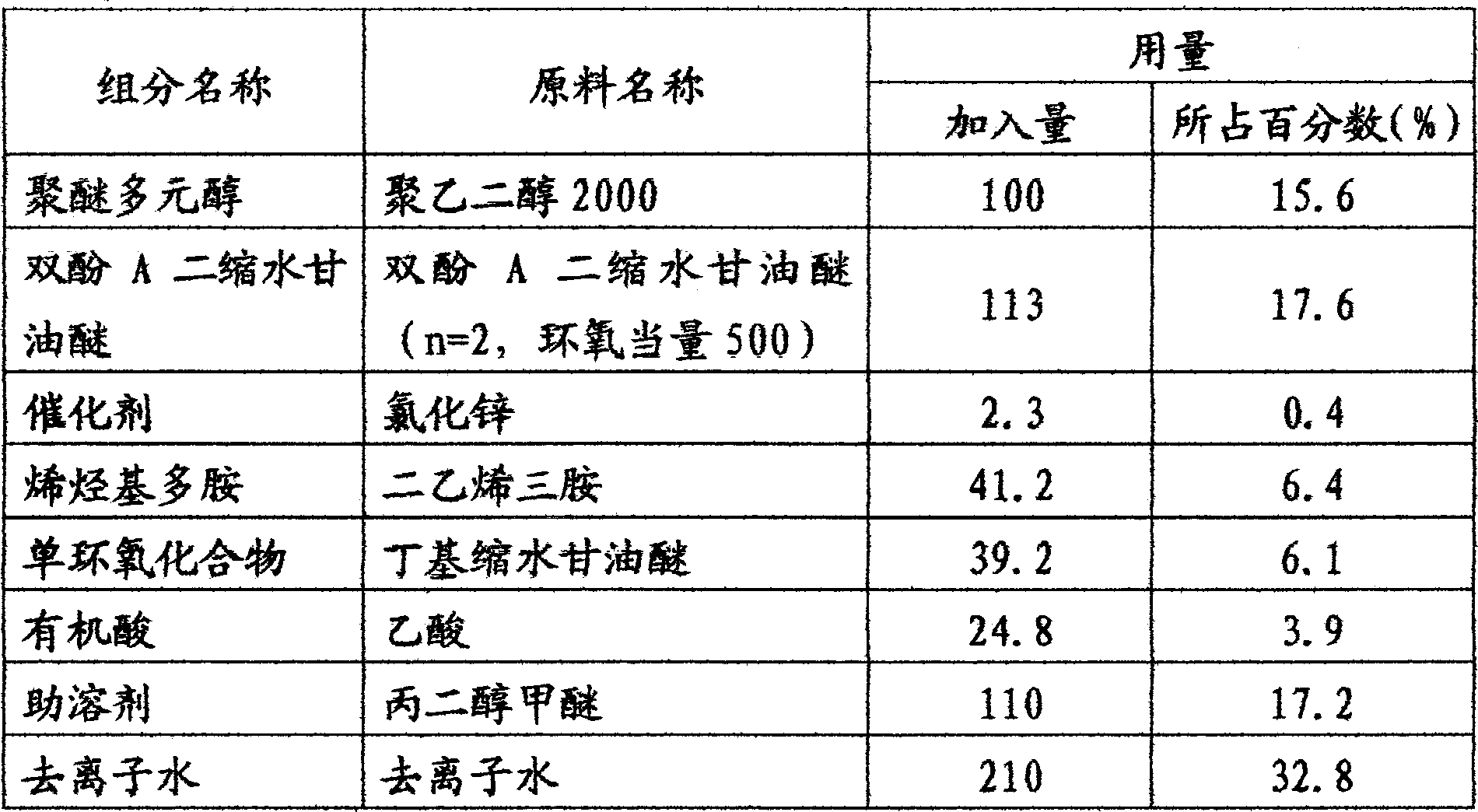

[0023] 1. See Table 1 for the formula

[0024] Table 1

[0025]

[0026] Note: "percentage" refers to the percentage of the total amount added.

[0027] 2. Operation method

[0028]In the reactor equipped with stirring, heating equipment, nitrogen conduit, reflux condenser and thermometer, enter 113 parts of bisphenol A diglycidyl ether and 100 parts of polyethylene glycol 2000 and 161 parts of xylene solvent, heat To the reflux temperature, stir until the material is completely dissolved, and add 2.3 parts of catalyst zinc chloride. At a reaction temperature of 125±5°C, react for 8 hours, lower the temperature to 50-60°C, add 41.2 parts of diethylenetriamine, keep the temperature for 1 hour, and obtain an amine-terminated epoxy adduct; then raise the temperature to 200°C, Distill at 200°C and 724mmHg for 10 minutes to remove the unreacted diethylenetriamine and xylene solvent, then vent ...

Embodiment 2

[0029] Embodiment 2 prepares the component B of two-component waterborne epoxy paint

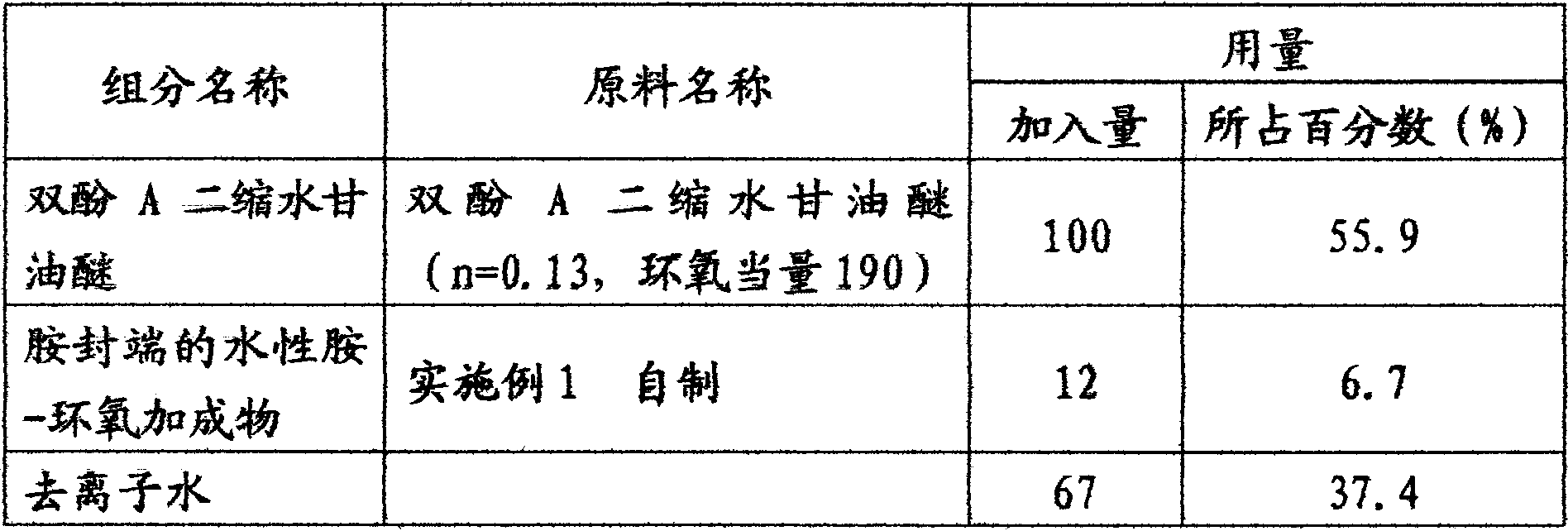

[0030] 1. See Table 2 for the formula

[0031] Table 2

[0032]

[0033] Note: "percentage" refers to the percentage of the total amount added.

[0034] 2. Operation method

[0035] In the reaction flask equipped with stirring, heating system, reflux condenser and thermometer, add bisphenol A diglycidyl ether and the amine-epoxy adduct obtained in Example 1 according to the formula in Table 2, drop while stirring Add deionized water until the deionized water is added to obtain component B. Its appearance is a white stable emulsion. The equivalent is 350-380.

Embodiment 3

[0036] Embodiment 3 prepares the component first of two-component waterborne epoxy paint

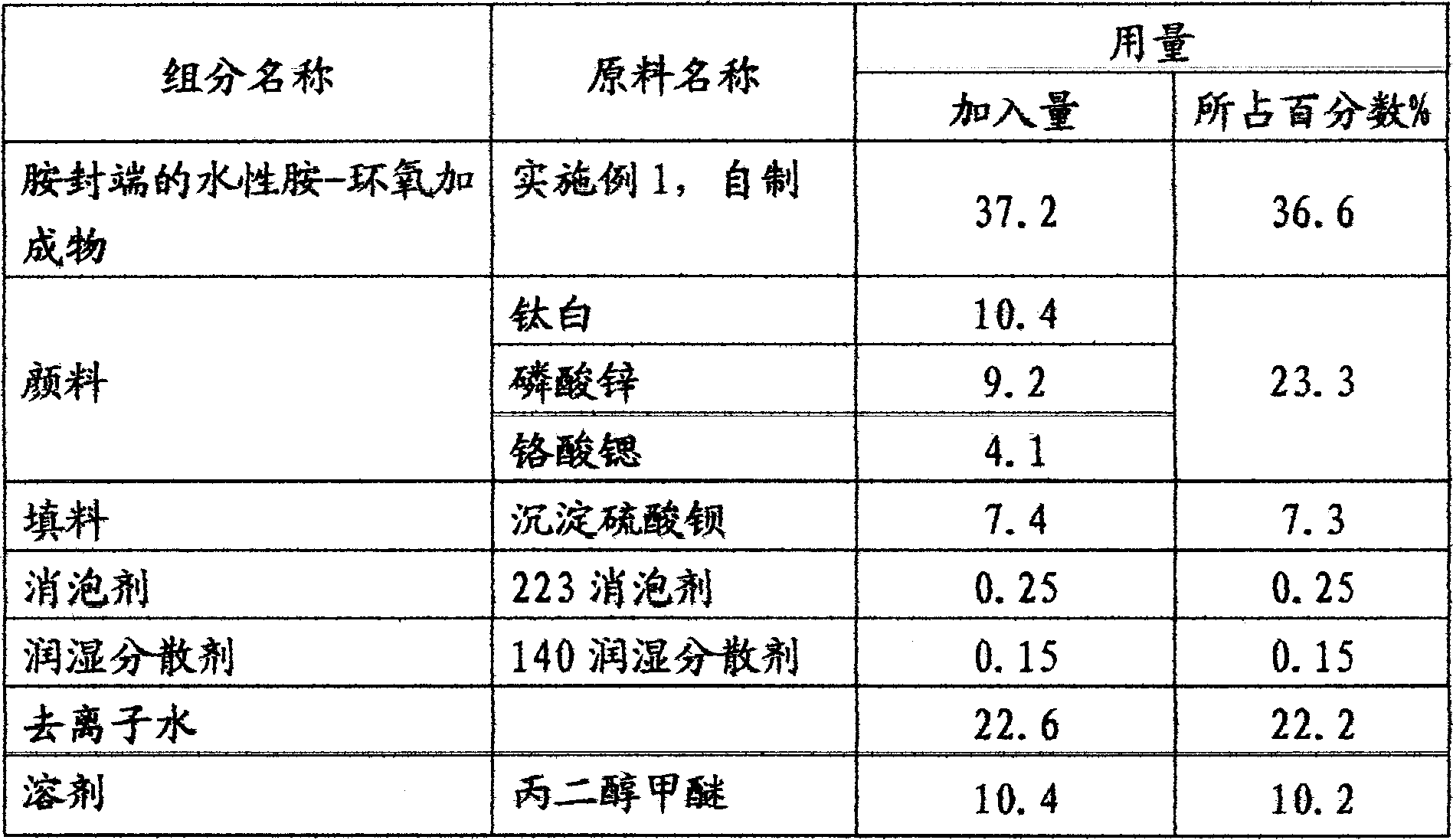

[0037] 1. See Table 3 for the formula

[0038] table 3

[0039]

[0040] Note: The 223 defoamer in the table is a mineral oil-based defoamer, and the 140 wetting and dispersing agent is an organically modified polysiloxane dipropylene glycol monomethyl ether solution, both of which are products of Shenzhen Haichuan Chemical Technology Co., Ltd.

[0041] 2. Operation method

[0042] In the container with stirring, first add the amine-terminated water-based amine-epoxy adduct, part of deionized water, propylene glycol methyl ether and part of 223 defoamer according to the formula in Table 3, and stir at a speed of 400 rpm for 20 Minutes, then add titanium dioxide, zinc phosphate, precipitated barium sulfate, strontium chromate, the remaining 223 defoamer, 140 wetting and dispersing agent and part of deionized water, and then stir at 400 rpm for 20 minutes, then use the remaining Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com