Plating solution for electroplating matt zinc and preparation thereof

A zinc plating solution, matte technology, applied in the field of surface treatment of metal materials, can solve the problems of many organic inclusions, easy discoloration of the coating, and many decomposition products, etc., and achieves the effect of high main salt content, soft luster and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

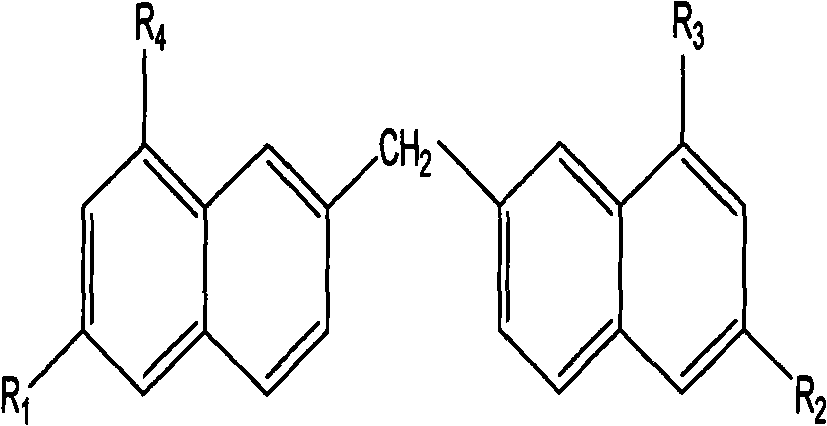

[0039] Embodiment 1: [preparation of methylene dinaphthalene]

[0040] a. Mix 9.0-12.8g of methylnaphthalene and 11.2g-13.8g of sulfuric acid, add it into a three-necked flask equipped with a thermometer and electric stirring, and react under strong stirring for 3-4 hours;

[0041] b. the mixed solution obtained in a is naturally cooled and crystallized at normal temperature;

[0042] c. Add the crystals obtained in b into a condensation reaction tank containing 6-9g formaldehyde, and condense for 2-3 hours under the condition of 168-196kPa;

[0043] d. Adding NaOH with a mass fraction of 40% to the condensation reaction tank to adjust the pH to 8-10;

[0044] e. the mixed solution obtained in d is naturally cooled and crystallized at normal temperature;

[0045] f. Filtrate to obtain the crystal in e, dry, and then use distilled water to configure a solution with a mass fraction of 40% to obtain methylene dinaphthalene.

Embodiment 2

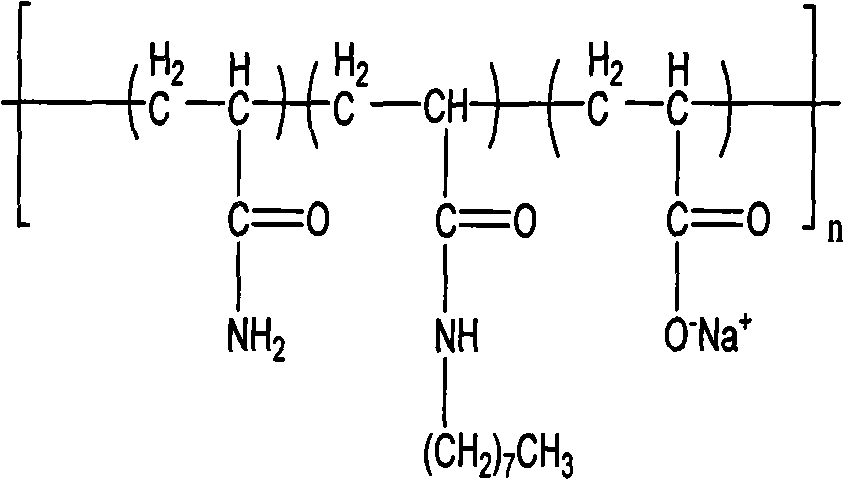

[0046] Embodiment 2: [preparation of poly(acrylamide / sodium acrylate N-octylacrylamide)]

[0047] a. Dissolve 0.024-0.028mol of triethylamine and 0.022-0.024mol of n-octylamine in 20-40ml of tetrahydrofuran;

[0048] b. Pour the mixture obtained in a into a four-necked bottle equipped with a thermometer, a nitrogen pipe, and an electric stirrer, and control the temperature at 0-5°C. Slowly drop 0.022-0.023 mol of acryloyl chloride into the four-necked bottle. Raise the temperature to 10-15°C, and keep it warm for 2-4 hours under the condition of vigorous stirring;

[0049] c. the mixed solution obtained in b is desolventized with a vacuum distillation device;

[0050] d. crystallize the mixed solution after desolvation in acetone at -5°C, the volume ratio of acetone and the mixed solution after desolventization is 2:1;

[0051] e. Add the crystals obtained in d., 20-30ml of deionized water, 0.022-0.0024mol of acryloyl chloride, and 0.5-0.8g of SDS (Sodium dodecyl sulfate) in...

Embodiment 3

[0054] Embodiment 3: [preparation of matte zinc intermediate]

[0055] a. Take 480-520g of n-octanol into a three-neck flask with stirring, add 5-8g of NaOH and 5-10g of water;

[0056] b. Stir vigorously and gradually heat up;

[0057] c. Dehydration under a vacuum of -0.05MPa;

[0058] d. Heat up to 110-120°C until dehydration is complete and continue to heat up to 150-200°C;

[0059] e. Exhaust air and inject nitrogen;

[0060] f. Add ethylene oxide under stirring, the reaction pressure is 0.2-0.4MPa, and the reaction temperature is 160-180°C;

[0061] g. Discharge when the cloud point is 40-50, put it into a three-necked flask with stirring, and heat up to 60-70°C;

[0062] h. Take 200-240g of sulfuric acid and add it dropwise, and control the temperature at 90-100°C. After dropping for 1 hour, cool down to 60-70°C and take 50% NaOH to adjust the pH to 6.5-7.5 to obtain the mother liquor;

[0063] i. The mother liquor is allowed to stand for stratification, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com