Amphiphilic polymer pigment dispersant for water paint

A technology of amphiphilic polymer and pigment dispersant, which is applied in the direction of pigment slurry and latex paint, etc., can solve the problems of unsatisfactory dispersion effect and achieve the effect of bright color, easy operation and uncomplicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Add 300 grams of methyl methacrylate, 240 grams of tert-butyl methacrylate, 60 grams of hydroxyethyl methacrylate, 200 grams of toluene and 200 grams of butyl acetate in a 2-liter three-necked flask, install a condenser tube, and High-purity nitrogen was passed through the mixture for 2 hours. Then, 36 mg of chain transfer agent (COPhBF) and 3 g of initiator azobisisobutyronitrile were added into the three-necked flask under nitrogen atmosphere. Under a nitrogen atmosphere, the system is reacted in a constant temperature water bath at 70-80° C. for 6-10 hours. A light yellow viscous macromonomer solution was obtained, and a light yellow solid was obtained after removing the solvent, the number average molecular weight Mn=860, the molecular weight distribution PDI=1.6, and the conversion rate was 80%.

Embodiment 2

[0083] Add 40 grams of methyl methacrylate, 160 grams of tert-butyl methacrylate, 150 grams of toluene and 150 grams of butyl acetate into a 1-liter three-necked flask, install a condenser, and pass high-purity nitrogen into the mixture for 2 hours . Then, 6 mg of chain transfer agent (COPhBF) and 1 g of initiator azobisisobutyronitrile were added to the three-necked flask under nitrogen atmosphere. Under a nitrogen atmosphere, the system is reacted in a constant temperature water bath at 70-80° C. for 6-10 hours. A light yellow viscous macromonomer solution was obtained, and a light yellow solid was obtained after removing the solvent, the number average molecular weight Mn=6100, the molecular weight distribution PDI=1.75, and the conversion rate was 95%.

Embodiment 3

[0085] 98 grams of the macromer obtained in Example 1, 33 grams of butyl acrylate, 1.3 grams of azobisisobutyronitrile and 130 grams of toluene were added to a 500 milliliter three-necked flask. Then react in a constant temperature water bath at 70-80°C for 6-10 hours. Then the solvent was evaporated with a rotary evaporator to obtain a light yellow solid with a number average molecular weight Mn=1300, a molecular weight distribution PDI=1.78, and a conversion rate of 100%. Add 150 grams of dioxane and 90 grams of concentrated hydrochloric acid, and react in a constant temperature water bath at 80-90° C. for 10-17 hours. Evaporate the solvent therein with a rotary evaporator, add an aqueous sodium hydroxide solution, and dissolve to obtain an aqueous solution of a grafted amphiphilic polymer dispersant.

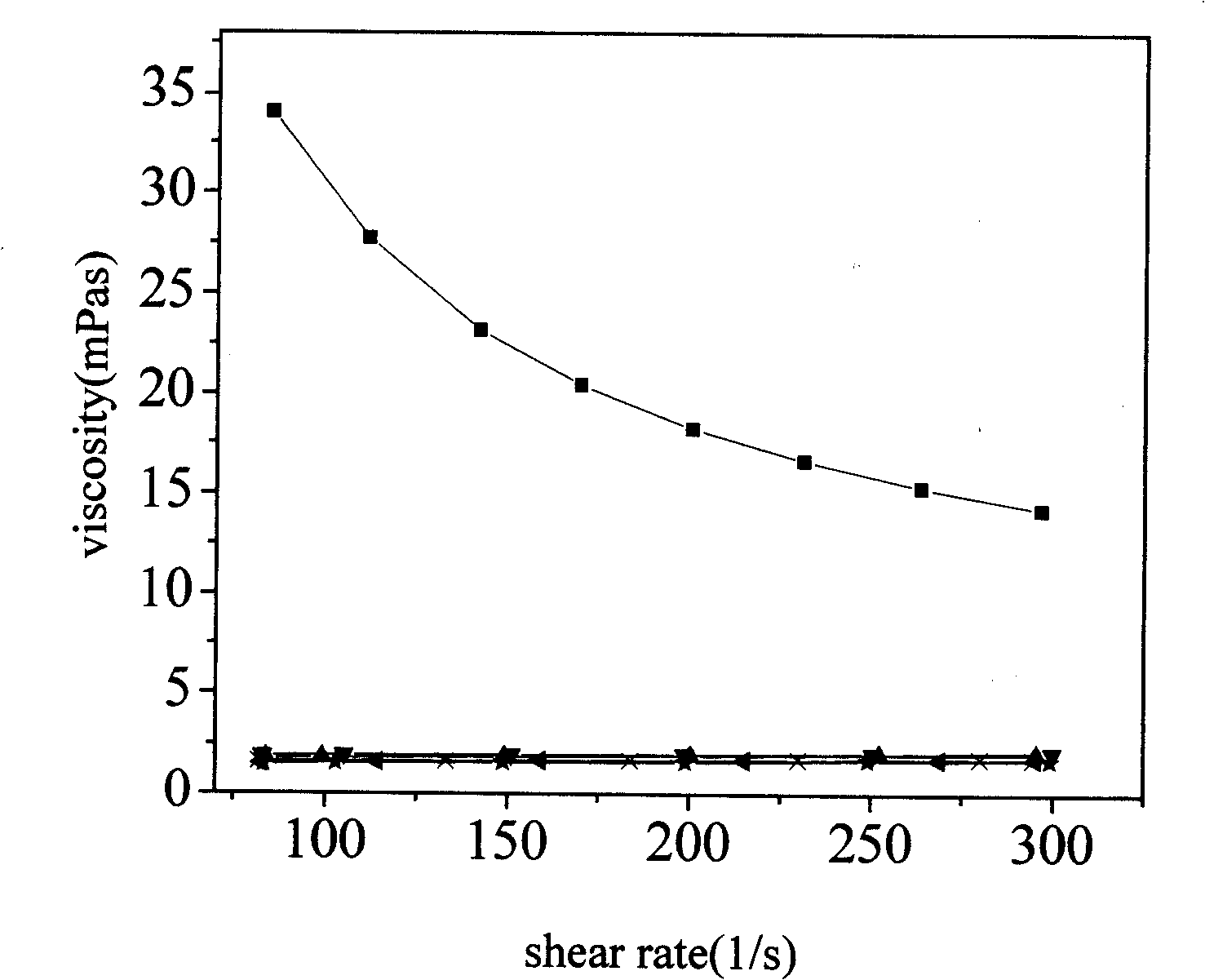

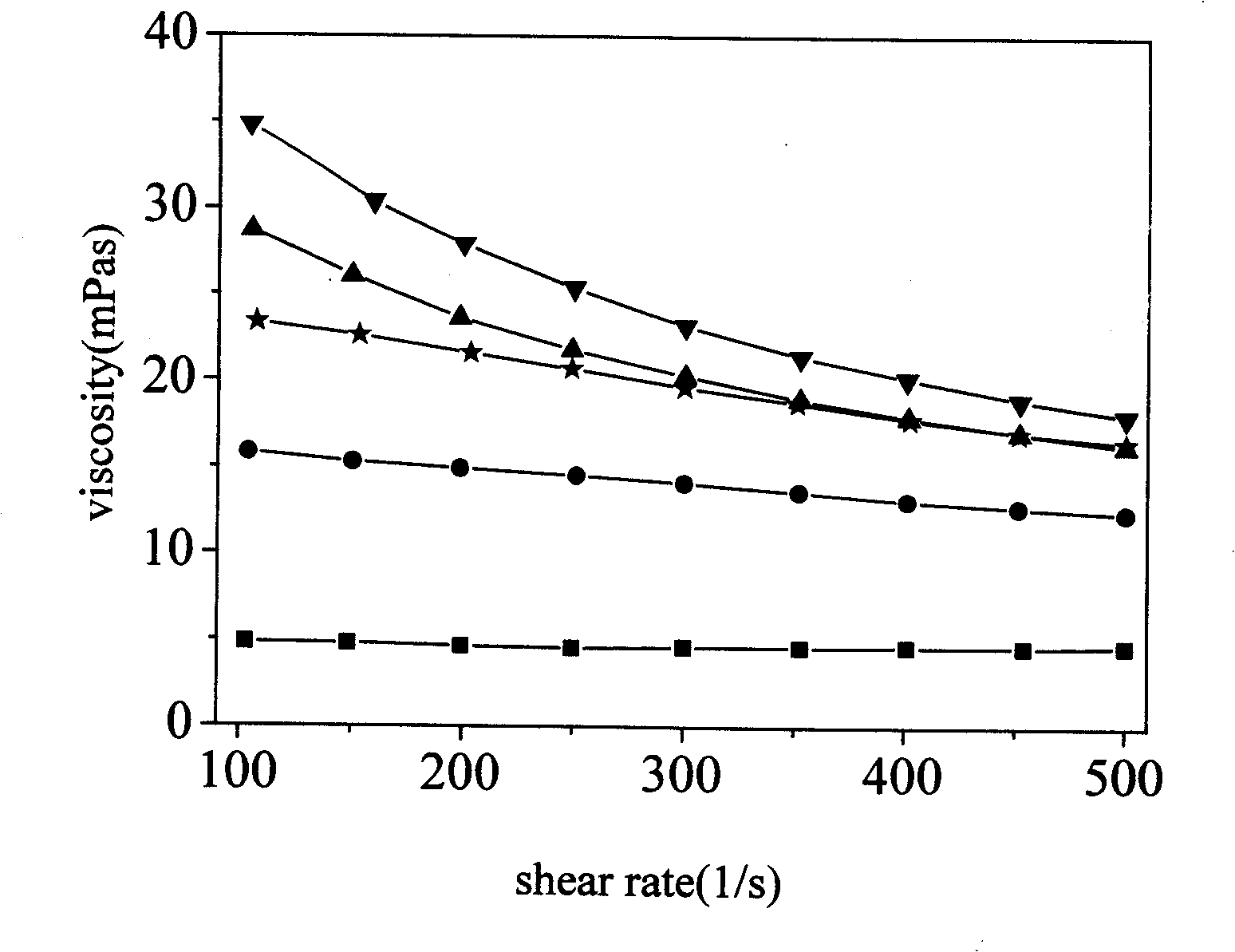

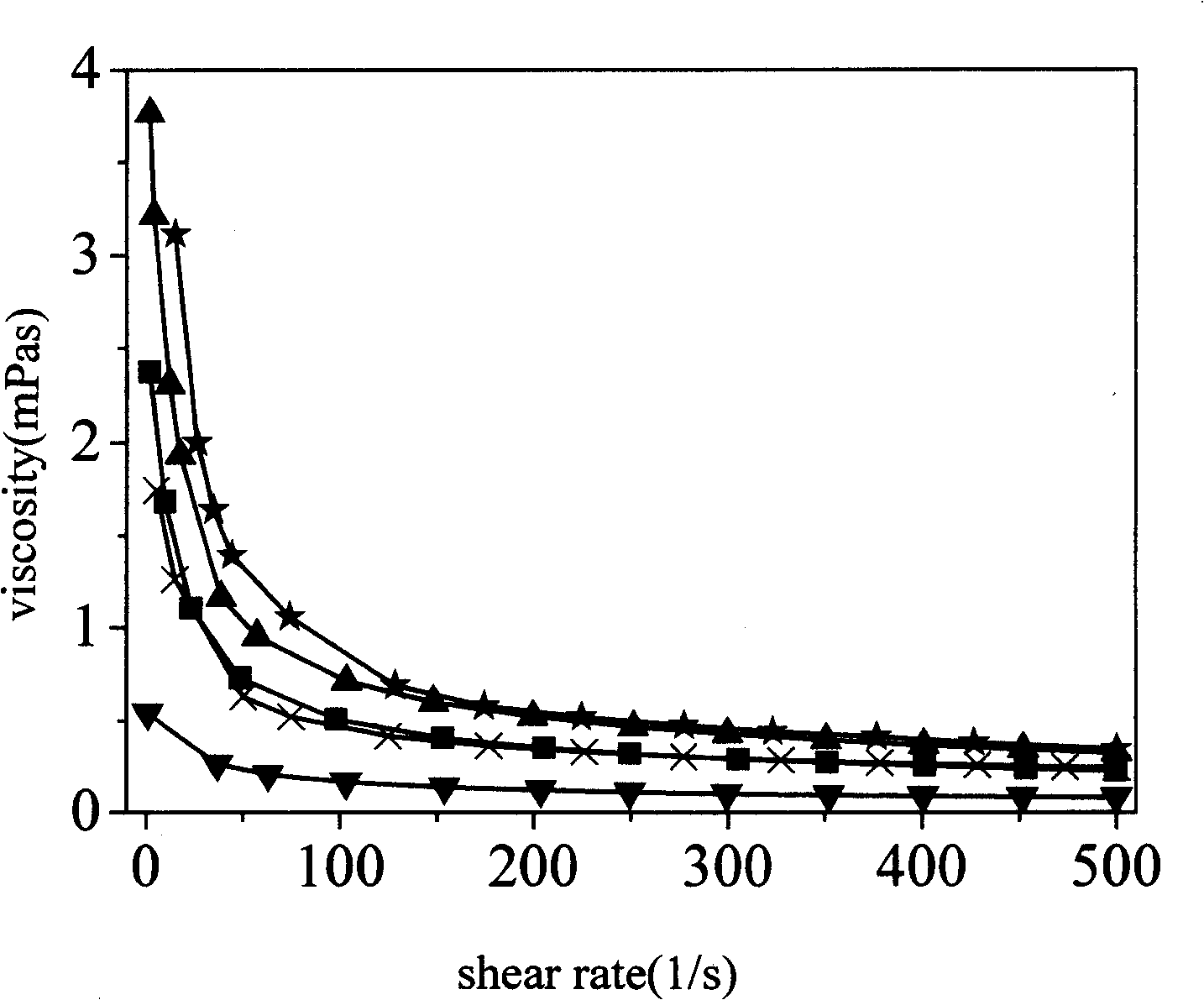

[0086] Wetting and dispersing test of this dispersant:

[0087] 1. Dispersion of carbon black

[0088] Carbon black: 2 grams

[0089] Dispersant: 0.2 g

[0090] Secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com