Pressure forming firework external cylinder and fireworks display marble casing and manufacturing method thereof

A technology of molding and shells, which is applied to the types of weapons, other household appliances, household components, etc., can solve the problems of easy deformation of the bobbin, irregular size, waste of materials, etc., to achieve high production efficiency, fewer processes, and ensure discharge safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

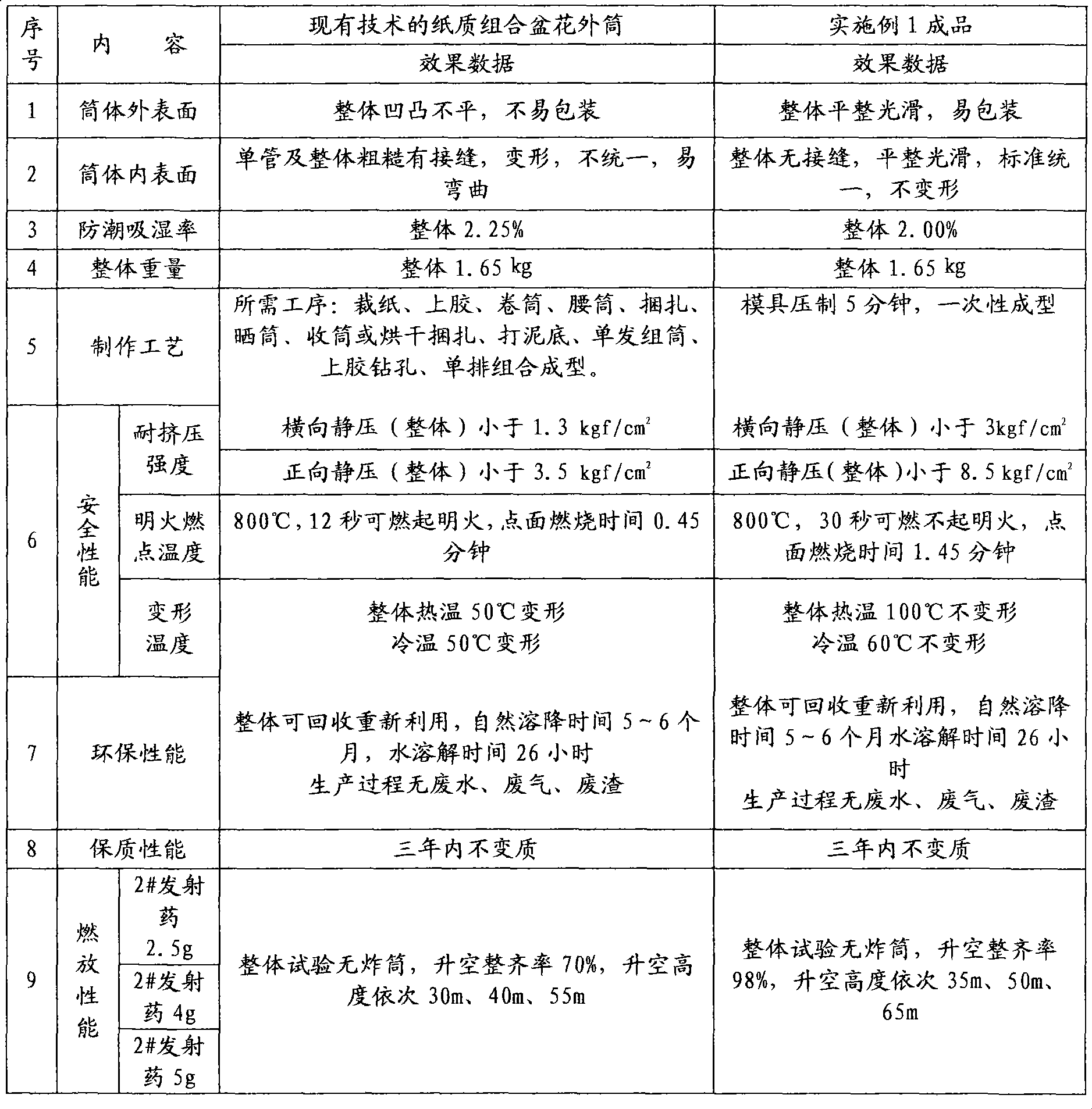

Embodiment 1

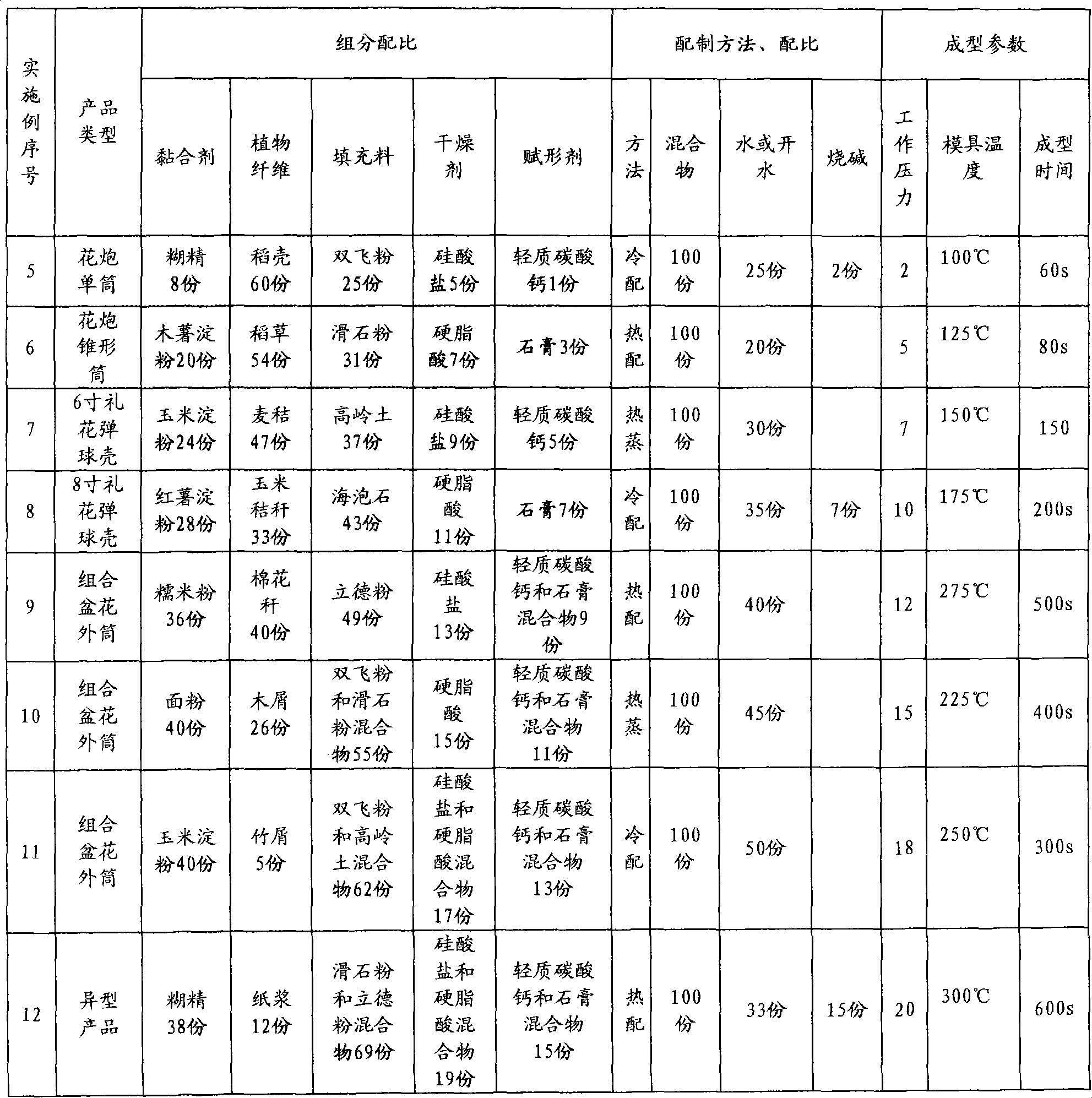

[0023] Embodiment 1, take making 19 rounds / height 17.5cm / inner diameter 0.3cm combination potted flower outer cylinder as example.

[0024] 1. According to the ratio of parts by weight, 12 parts of tapioca starch, 8 parts of wood chips, 10 parts of paper pulp, 55 parts of Shuangfei powder, 1.5 parts of stearic acid, 5 parts of gypsum, and 8.5 parts of light calcium carbonate were weighed for each raw material component, The components are mixed in a general way; boiled water is added according to the weight ratio of 100 parts of the above mixture plus 30 parts of boiled water and stirred evenly.

[0025] 2. Take 2.4kg of the product obtained in the previous step, put it into the mold frame of the potted flower outer cylinder with 19 rounds / height 17.5cm / inner diameter 0.3cm, set the working pressure of the hydraulic press to 10 kgf / cm2, press and shape, and at the same time through electric heating The mold is heated to 200°C to dry and set, and after 5 minutes, the mold is de...

Embodiment 2

[0027] Embodiment 2, taking the thick spherical shell of making R45 millimeter * 4 millimeters as example:

[0028] 1. By weight: 6.5 parts of cornstarch, 6.5 parts of glutinous rice flour, 7.5 parts of rice husk, 6.5 parts of paper pulp, 57.5 parts of Shuangfei powder, 4.5 parts of silicate, 11 parts of light calcium carbonate, and weigh each raw material component , mix each component by general method; add boiled water according to the weight ratio of 100 parts of the above mixture plus 25 parts of water and stir evenly.

[0029] 2. Take 65 grams of the product obtained in the previous step, put it into a 4-inch spherical shell mold frame, use a pressurized cylinder device to set the working pressure at 5 kgf / cm2, and press it into shape, and at the same time heat the mold to 200°C for drying through oil temperature Dry setting, demoulding after 1 minute and 20 seconds to obtain the finished product.

[0030] Compared with the existing paper spherical shell of the same spe...

Embodiment 3

[0032] Embodiment 3, take making special-shaped product " grenade " (grenade profile) and " frog prince " (frog profile) as example:

[0033] 1. parts by weight: 15 parts of flour, 5 parts of straw, 10 parts of paper pulp, 10 parts of sawdust, 48.5 parts of talcum powder, 1.5 parts of stearic acid, 10 parts of light calcium carbonate, each raw material component is weighed, each The components are mixed in a general way; boiled water is added according to the weight ratio of 100 parts of the above mixture plus 45 parts of water and stirred evenly.

[0034] 2. Take the product obtained in the previous step as needed and put it into the mold frame, use the pressurized cylinder equipment to set the working pressure to 20 kgf / cm2 for pressing and molding, and at the same time, heat the mold to 200 °C for 2 minutes. After 20 seconds, the mold is demoulded to obtain the finished product.

[0035] The difficulty in the development of special-shaped products in the fireworks industry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com