Method for constructing genetic engineering bacteria and enhancing stress resistance of 1,3-propanediol producing strain

A technology of genetically engineered bacteria and production strains, applied in the field of constructing genetically engineered bacteria enhancement 1, to achieve the effects of reducing production costs, improving raw material utilization, and reducing fermentation abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] (1) Construction of genetically engineered bacteria

[0048] (i) Wild strain: Klebsiella AC01

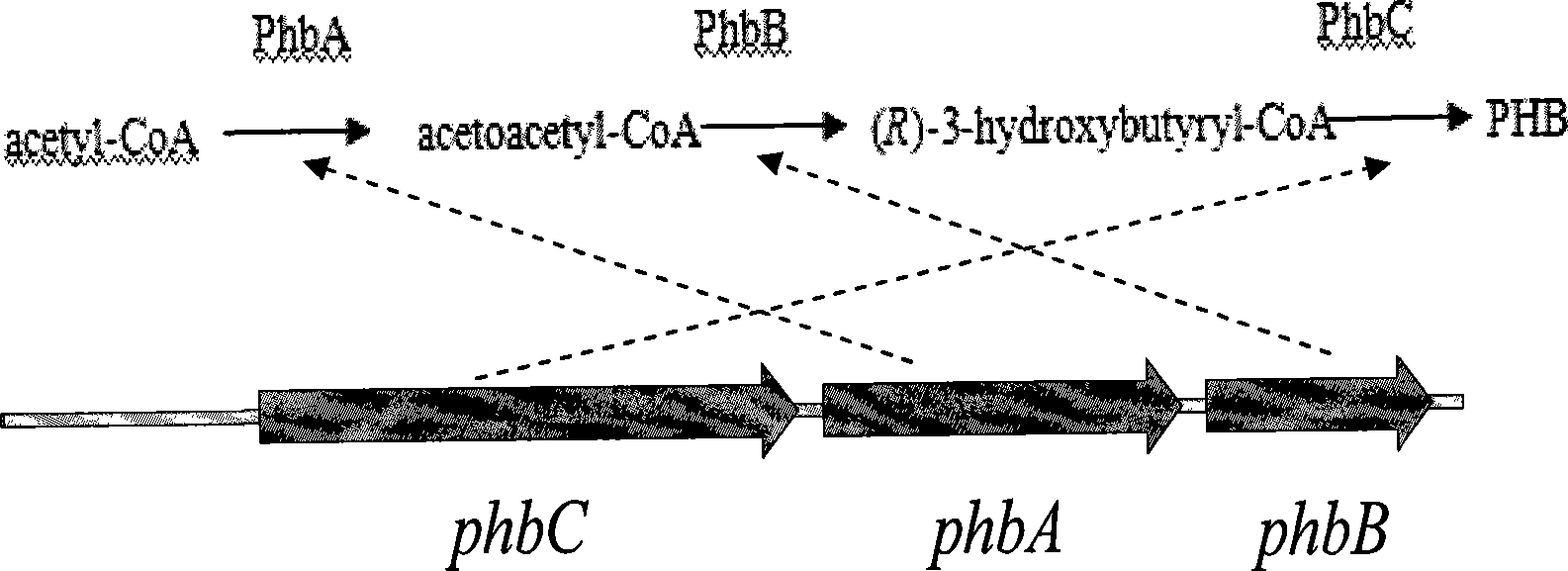

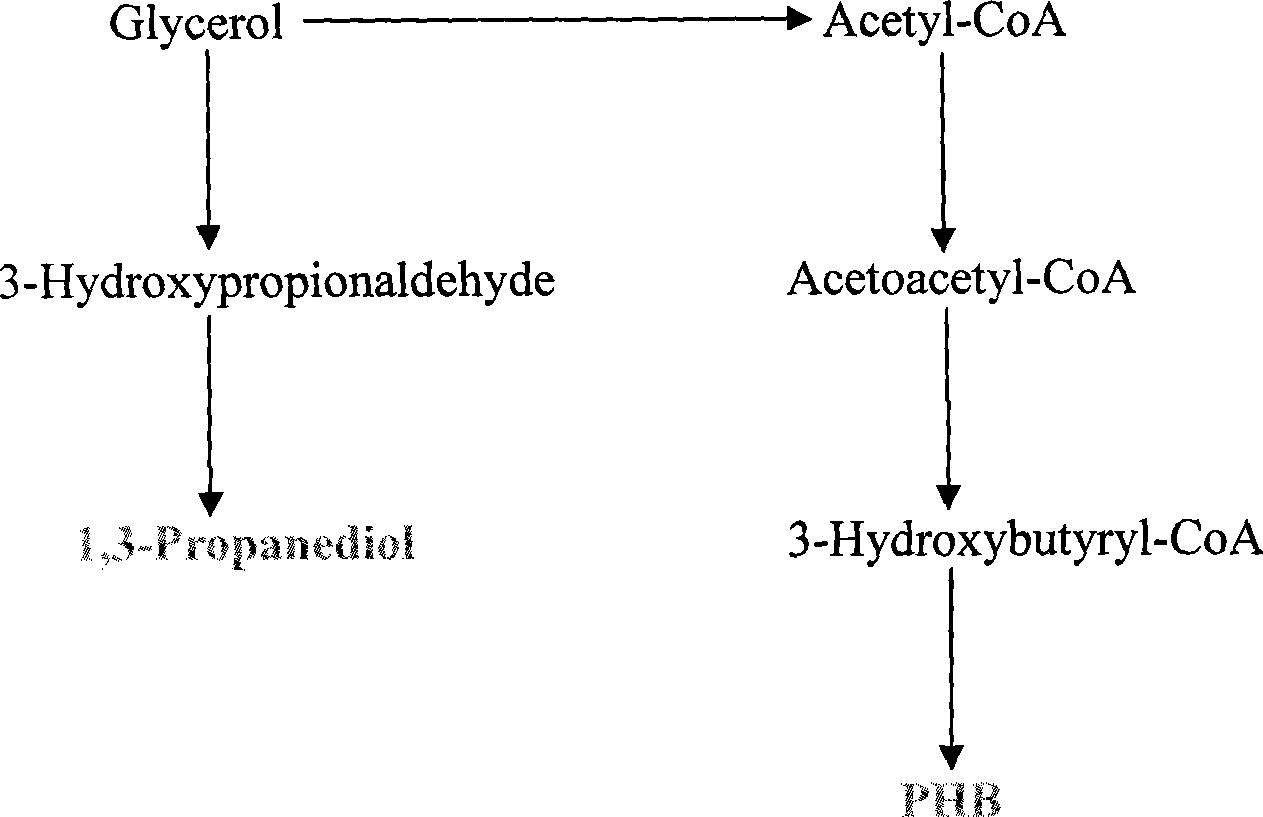

[0049] (ii) Using the plasmid pBHR68 carrying the β-ketoacetyl-CoA thiolase (phbA), NADPH-dependent acetoacetyl-CoA reductase (phbB) and polyhydroxyfatty acid synthase (phbC) genes as a template, by PCR (polymerase chain reaction) method to completely clone its operon (phbCAB). PCR amplification conditions were as follows: pre-denaturation at 96°C for 8 min; denaturation at 96°C for 1 min, annealing at 62.5°C for 1 min, extension at 72°C for 4.5 min, 30 cycles; extension at 72°C for 10 min.

[0050] phbL: 5'-CCCGAATTC(EcoRI)CTGACGGCAGAGAGACAATC-3'

[0051] phbR: 5'-TATGGATCC(BamHI)TGCCGACTGGTTGAACCAG-3'

[0052] (iii) After purifying the PCR product β-ketoacetyl-CoA thiolase, NADPH-dependent acetoacetyl-CoA reductase and polyhydroxy fatty acid synthase gene fragments, they were connected to the cloning vector pMD18-T-vector and transformed into a competent state In E. col...

example 2

[0140] (1) Construction of genetically engineered bacteria

[0141] (i) Wild strain: Klebsiella HR521

[0142] (ii) with embodiment one

[0143] (iii) with embodiment one

[0144] (iv) with embodiment one

[0145] (v) with embodiment one

[0146] (vi) Extract the recombinant expression vector pDK-CAB from the positive clone, and transform it into the competent cells of wild-type Klebsiella HR521 by electroporation, identify and isolate the positive clone, which is the target strain HR521 -PHB.

[0147] (2) fermentation

[0148] (i) Strain: the constructed target strain HR521-PHB

[0149] (ii) culture medium: with embodiment one

[0150] (iii) Fermentation method: the constructed genetically engineered bacterium was cultivated on a solid medium for 24 hours, the bacterial classification was inserted into a seed medium containing 30g / L glycerol (250ml Erlenmeyer flask, 100ml liquid volume), and the culture temperature was 37 ℃, shaker speed 150rpm, aerobic culture for 18h....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com