Method for preparing hydroxylapatite/chitosan composite coating by pulse electrochemical deposition

A hydroxyapatite and composite coating technology is applied in the field of surface modification of medical biological materials, which can solve the problems of single constant current or constant voltage mode, uneven distribution of chitosan, and can not solve the problem of uneven coating. , to achieve the effect of uniform distribution, tight bonding and no agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Take the titanium plate as the working electrode.

[0020] (2) obtain the chitosan homogeneous solution that concentration is 1% with 2% acetic acid dissolving, get its 10ml;

[0021] (3) Get analytically pure calcium nitrate tetrahydrate 0.1416g, diammonium hydrogen phosphate 0.0792g, dissolve with ethanol and distilled water respectively, mix with (2), be configured into 200ml of calcium-phosphorus solution of pH=6.0 (adjusted with ammonia water), and The beaker is placed on a magnetic stirrer to stir, and finally a uniform electrolyte is obtained;

[0022] (4) With the uniform electrolyte in (3), the saturated calomel electrode is used as the reference electrode, the platinum sheet is used as the counter electrode, and the biomedical metal to be coated is used as the working electrode. deposition. The relevant parameters are: pulse high potential: -1.2V, pulse low potential: -2.0V, pulse width: 100s, deposition time: 25min.

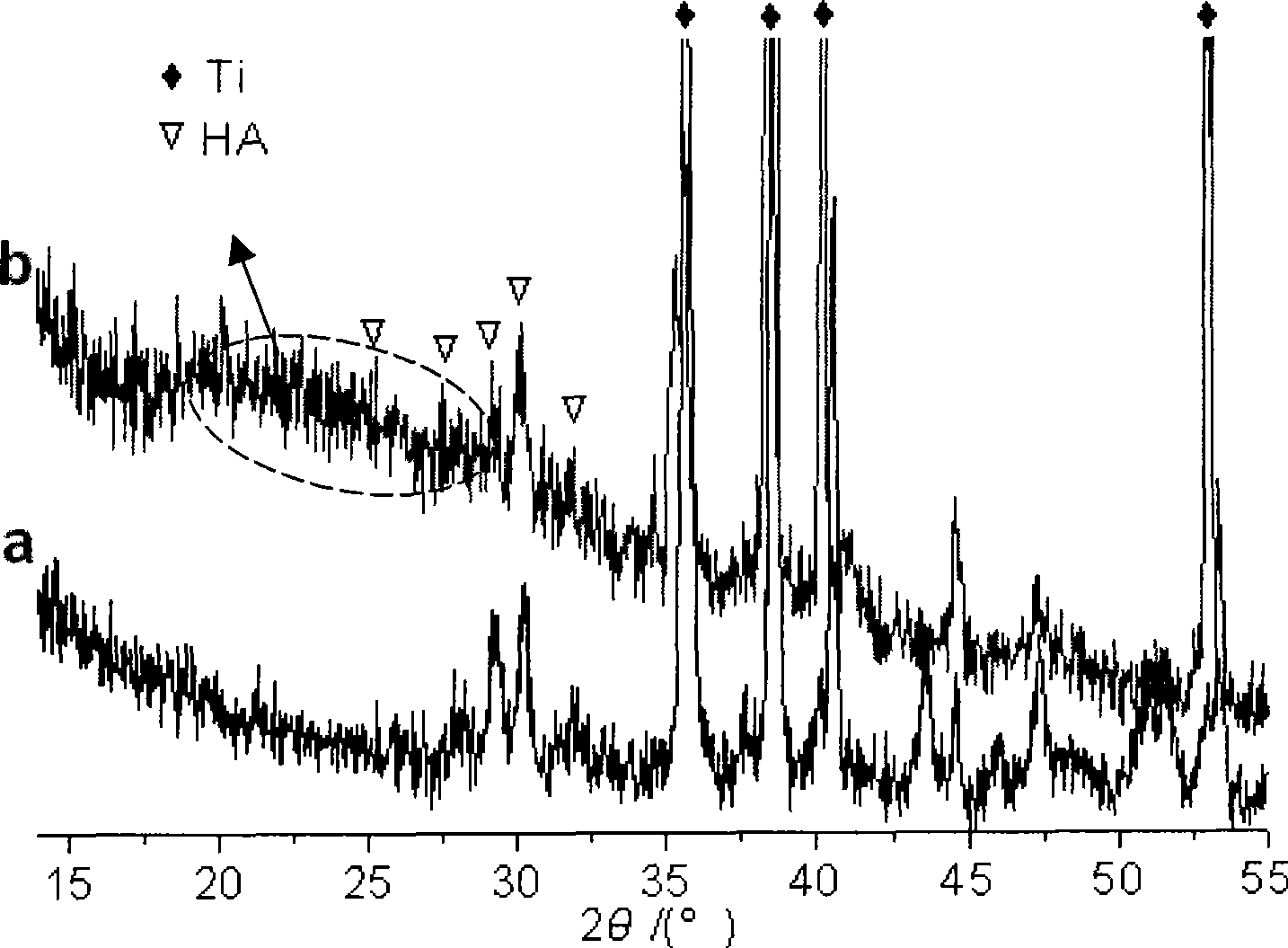

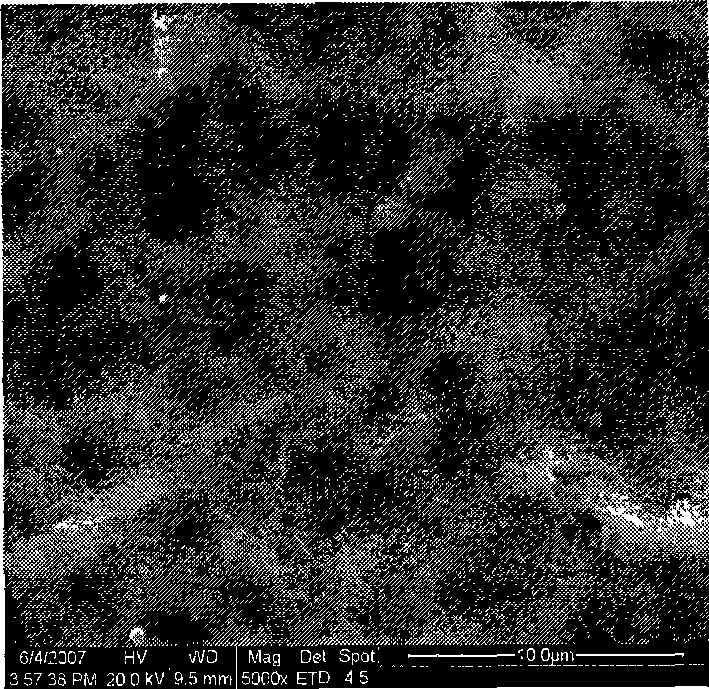

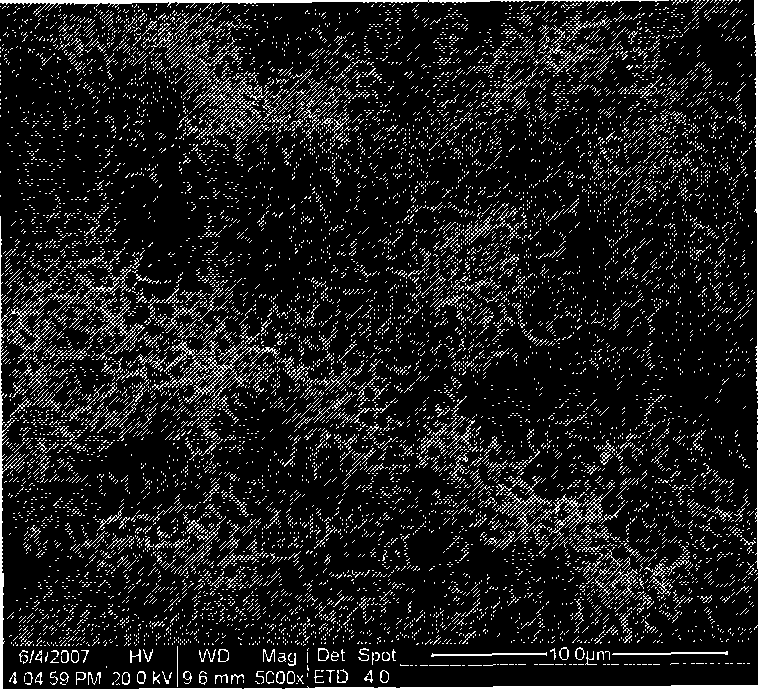

[0023] The XRD collection of illus...

Embodiment 2

[0027] The diammonium hydrogen phosphate of embodiment 1 is changed into the Na of equimolar concentration 2 HPO 4 , for electrochemical deposition, other conditions remain unchanged.

Embodiment 3

[0029] The diammonium hydrogen phosphate of embodiment 1 is changed into the K of equimolar concentration 2 HPO 4 , for electrochemical deposition, other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com