Uses of color value optimizing factor special for pressing candy

A technology for optimizing factors and color values, applied in applications, food preparation, food science, etc., can solve the problems of extensive internal management, no advantages, high cost, etc., and achieve the effects of reducing the risk of clogging, avoiding the formation of pseudocrystals, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

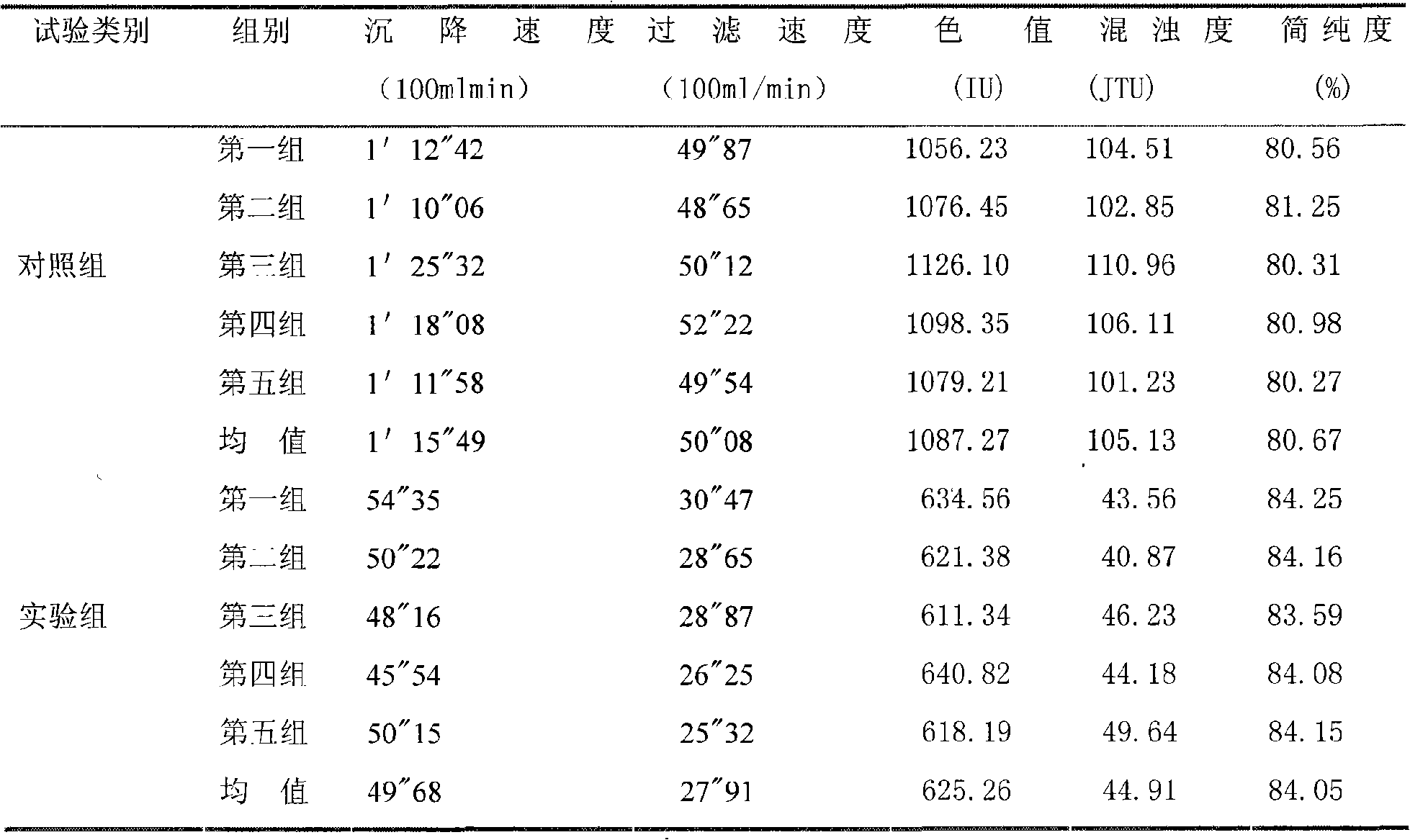

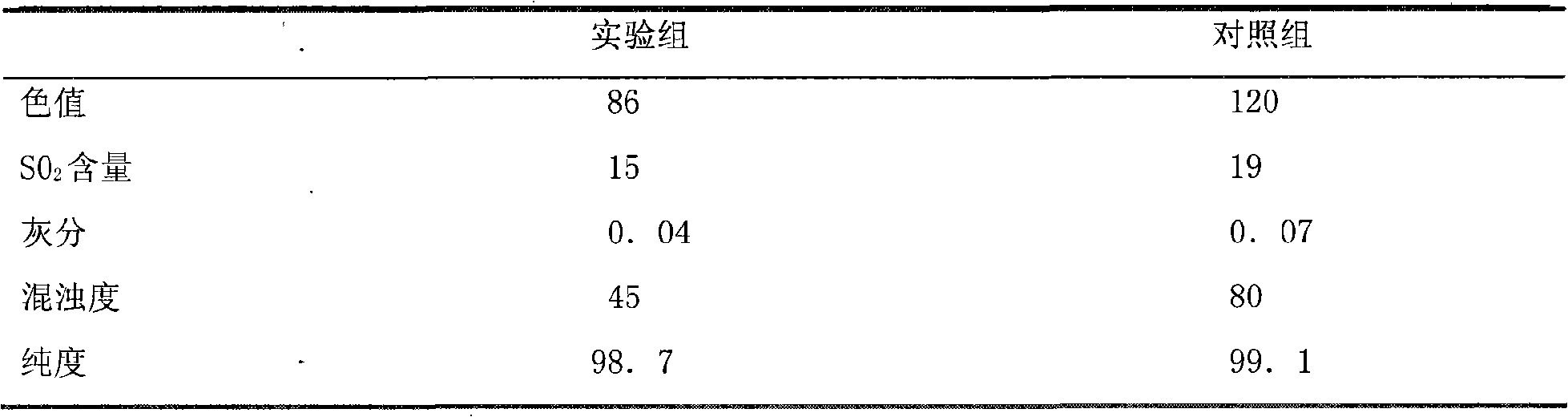

Examples

Embodiment 1

[0042] Embodiment 1: the specific formula of the present invention is as follows, and content is the composition of weight percent: dextranase 35%, pectinase 12%, xylanase 9%, laccase 10%, amylase 8%, reducing sugar oxidation Enzymes 3%, Antioxidants 2%, Purified Water 21%. The preparation method is as follows: the raw material enzymes are subjected to pretreatment respectively, filtered by a microfiltration membrane, then mixed in an automatic mixer in proportion, filtered through a fine filtration membrane, and quantitatively filled to become a product.

Embodiment 2

[0043] Embodiment 2: the specific formula of the present invention is as follows, and content is the composition of weight percent: dextranase 20%, pectinase 21%, xylanase 15%, laccase 10%, amylase 8%, reducing sugar oxidation Enzyme 3%, Antioxidant 3%, Purified Water 20%. The preparation method is the same as Example 1.

Embodiment 3

[0044] Embodiment 3: the specific formula of the present invention is as follows, and content is the composition of weight percent: dextranase 20%, pectinase 20%, xylanase 10%, laccase 10%, amylase 15%, reducing sugar oxidation Enzymes 3%, Antioxidants 2%, Purified Water 20%. The preparation method is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com