White potato shaped silicon dioxide colloidal sol and method of producing the same

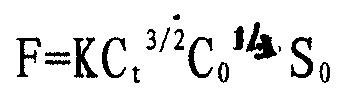

A silicon dioxide and potato technology, applied in the direction of chemical instruments and methods, other chemical processes, polishing compositions containing abrasives, etc., can solve problems such as small friction coefficient, scratches on workpieces, and affect polishing efficiency, and achieve friction The effect of large coefficient, less scratches and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of potato-shaped silica sol, carry out according to the following steps:

[0031] 1. Preparation of starting sol

[0032] (1). Containing SiO 2 In the active silicic acid solution of 1-6% by weight and pH=2-4, add water-soluble calcium salt, magnesium salt or their mixture aqueous solution, calcium salt, magnesium salt or their mixture and the SiO 2 The weight ratio reaches 1200-8000PPm for mixing;

[0033] (2). Add an alkali metal hydroxide or a water-soluble solution of an organic base to the aqueous solution prepared above and mix to make SiO 2 / M 2 The molar ratio of 0 is 20-200, PH=7.5-9.5, wherein M represents a metal atom or an organic base molecule;

[0034] (3). Heating the above solution at a temperature of 60°C-150°C and a heating and stirring time of 0.5-4 hours to make a receiver sol for particle growth;

[0035] (4). The above-mentioned sol is exchanged with a mixed bed of cations and anions to further remove anions and ca...

Embodiment 1

[0048] Commercially available sodium silicate (SiO 2 / M 2 O) molar ratio is 3.24, SiO 2 The content is 29.2% and pure water is added to make SiO 2 Concentration is 3.8% (weight ratio) sodium silicate aqueous solution, above-mentioned dilute sodium silicate aqueous solution is equipped with 500kg treated and regenerated cation exchange resin 001 * 7Styrene-DVB through 800 * 2000cm, obtains SiO 2 Concentration is 3.52% (weight ratio) acidic active silica gel solution; Put into 300kg above-mentioned acidic active silicic acid in the 500 liters of stainless steel retorts that condenser, agitator are housed, add 800g 10% CaCl under stirring at room temperature 2 Aqueous solution, after stirring for 1 hour, add 10% NaOH aqueous solution dropwise, adjust the pH to about 7.5-8.5, heat to 100°C and stir for 2 hours. The alkaline sol prepared above is cooled and passed through a strong alkaline anion and Mixed bed of strongly acidic cation exchange resin. Obtain an alkaline sol with a ...

Embodiment 2

[0050] Prepare acidic active silica gel solution with embodiment 1;

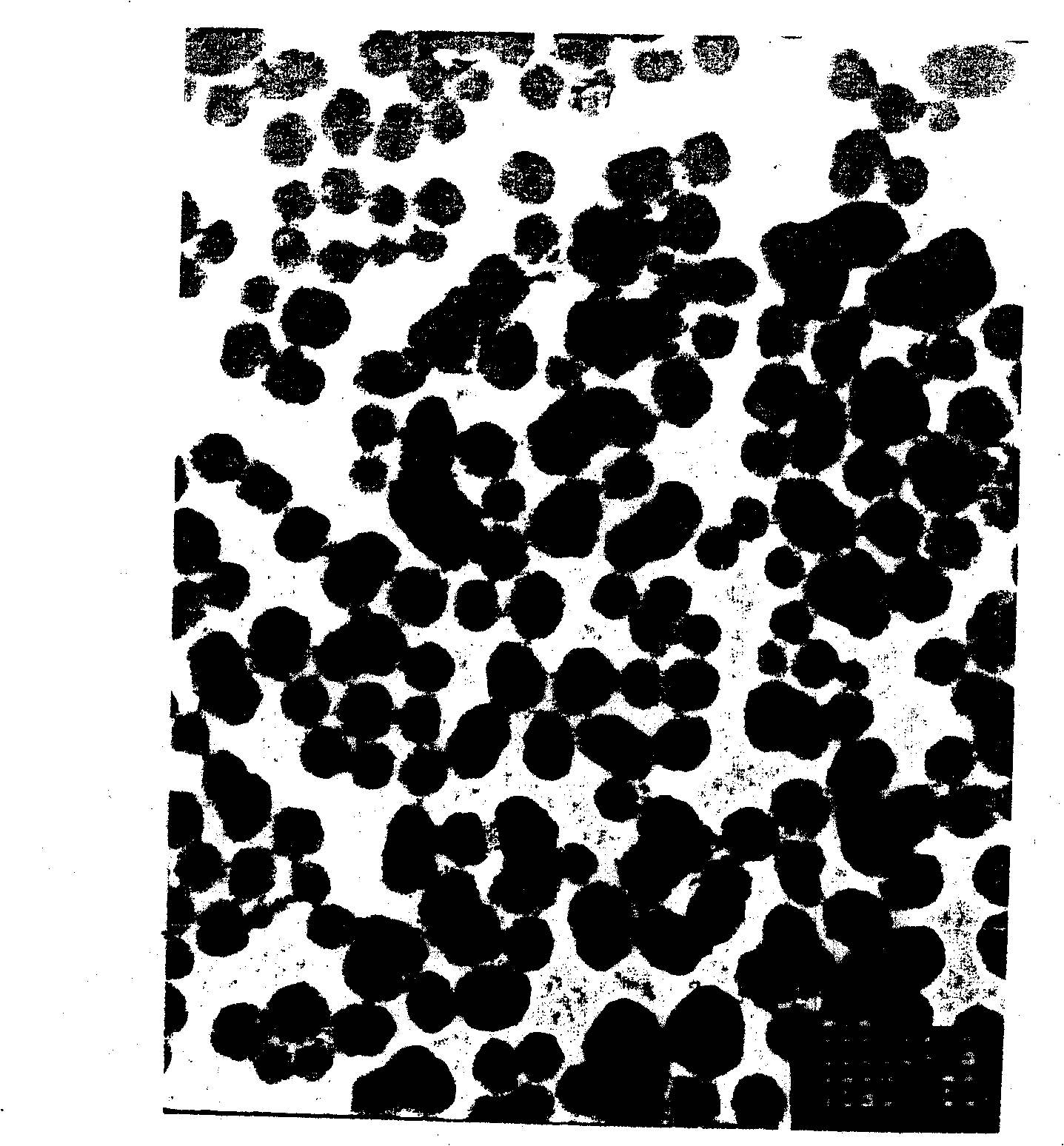

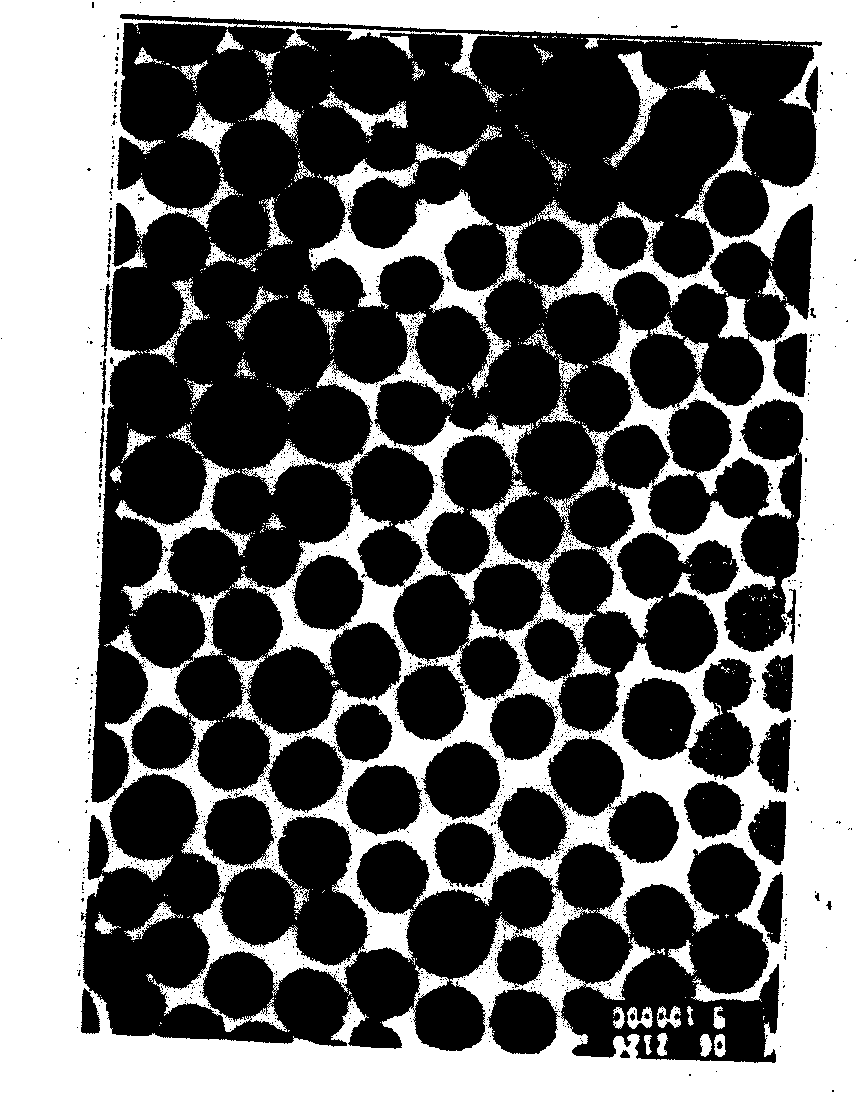

[0051] In a 500-liter stainless steel pressure reaction tank with stirring, put 300kg of the above-mentioned acidic active glue solution, add 800g of 10% CaCl under stirring at room temperature 2 Aqueous solution, after stirring for half an hour. Add dropwise 10% NaoH aqueous solution to adjust PH=7.5-8.5, heat at 120°C, and stir for 4 hours. After cooling, take it out and transfer to In the distillation tank, heat at 100°C, under vigorous stirring. Add acidic active sol dropwise, the dropping rate is 90 liters / hour, the speed of distilling water is 90 liters / hour, distilling water to keep the liquid level unchanged, after 26 hours, Get SiO 2 Alkaline silica sol with a content of 32%, pH=9.5, and a viscosity of 6.5C.P. Observation of SiO by transmission electron microscope 2 The particles are potato-shaped, with a particle size of 40-70nm.

[0052] comparative experiment

[0053] Pressure Test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com