Saccharomyces cerevisiae mutant bacterial strain and use thereof in glutathion production by fermentation

A mutant strain, Saccharomyces cerevisiae technology, applied in fermentation, microbial-based methods, enzymes, etc., can solve the problems of limited biomass accumulation, reduced microbial fermentation capacity, and unstable yeast quality, achieving reduction in bacterial contamination, Good pH tolerance, beneficial to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

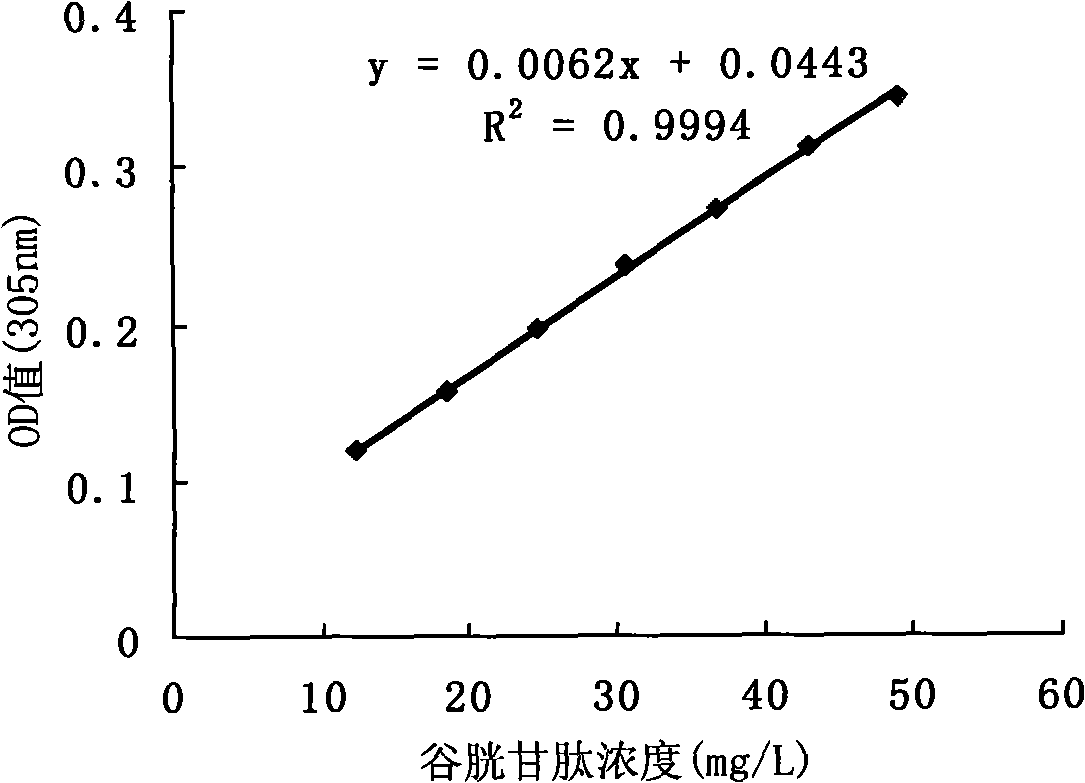

[0024] This example illustrates a method for measuring glutathione (GSH), a fermentation product of Saccharomyces cerevisiae, and uses this method as an evaluation basis for screening high-yielding Saccharomyces cerevisiae mutant strains.

[0025] GSH reacts with alloxan under test conditions to produce the highest absorption peak at 305nm, so this method is also called alloxan 305 method. The sulfhydryl group of cysteine can also react with alloxan, but its absorption peak is at 275nm, which will not interfere with the determination of GSH.

[0026] Draw a standard curve:

[0027] (1) Accurately weigh 0.006g of GSH standard substance, dissolve it with 40% ethanol, and set the volume to 100mL to obtain a GSH standard solution with a concentration of 200 μmol / L;

[0028] (2) Take 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9mL of the above-mentioned GSH standard solution in a test tube, add deionized water to 1.0mL, and prepare the concentration to be 0, 20 , 40, 60, 80, 1...

Embodiment 2

[0032] This example illustrates the mutagenesis screening method for S. cerevisiae Y518.

[0033] 1. Preparation of bacterial cell suspension

[0034] Inoculate and activate the active dry Saccharomyces cerevisiae purchased from Hubei Angel Yeast Co., Ltd., pick a ring of bacteria from the activated slant and inoculate it into 20mL basal medium. Insert 200 mL of basal medium into a 500 mL Erlenmeyer flask at 30°C, shake at 180 rpm, take out 10 mL of culture solution, centrifuge at 6000 rpm for 15 min and wash twice with normal saline, then add 0.1 mol / L phosphate buffer at pH 6.0, Hemocytometer adjusted cell concentration to 106cfu / mL.

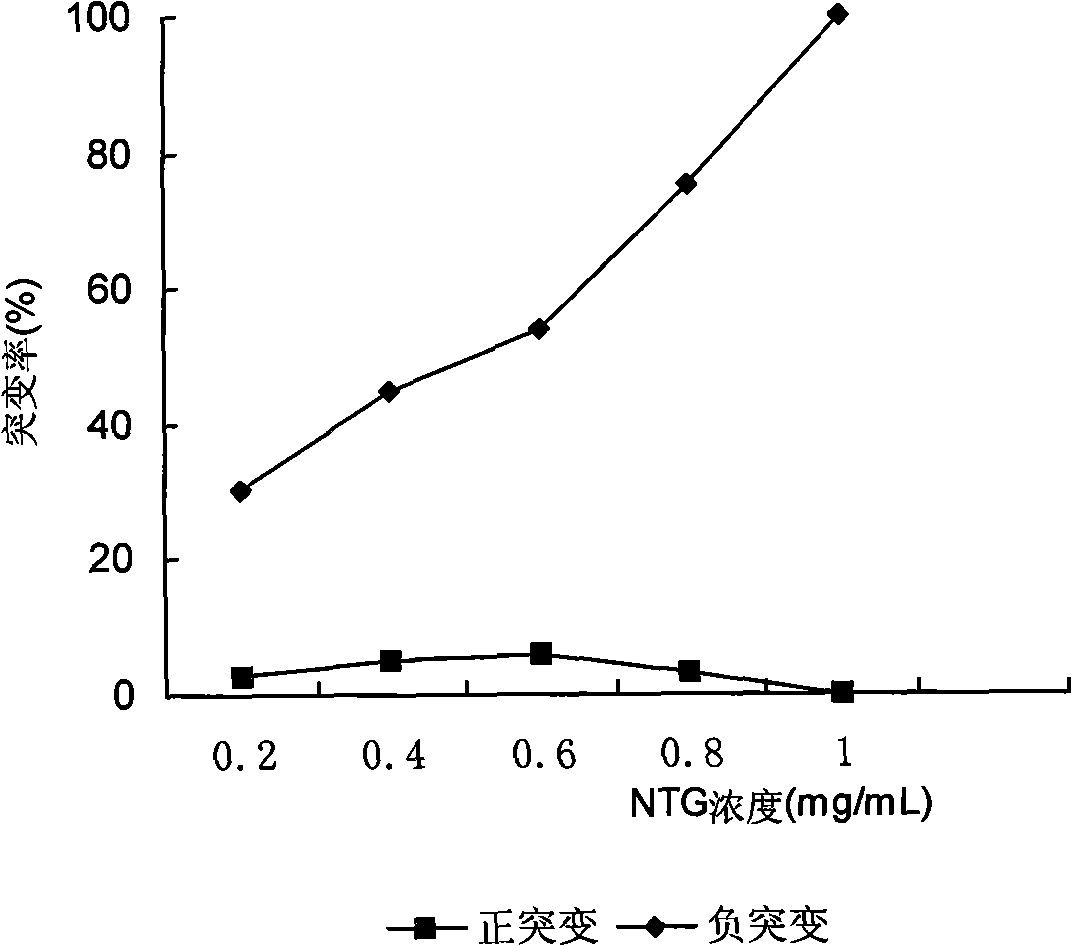

[0035] 2. Nitrosoguanidine (NTG) mutagenesis and determination of optimal mutagen concentration

[0036] Mix the bacterial suspension with 10 mg / mL NTG according to a certain ratio, so that the final concentrations of NTG are 0, 0.2, 0.4, 0.6, 0.8, 1.0 mg / mL, treat at 30 ° C for 30 min, add 2% Na 2 S 2 o 3 After the reaction was terminat...

Embodiment 3

[0063] This example illustrates the isolation and cloning procedure of the γ-glutamylcysteine synthetase gene and the glutathione synthetase gene in Saccharomyces cerevisiae Y518.

[0064] Wherein, the extraction of genomic DNA of Saccharomyces cerevisiae Y518 strain adopts phenol-chloroform extraction method.

[0065] 1. Isolation and cloning of γ-glutamylcysteine synthetase gene:

[0066] Get the genomic DNA of Saccharomyces cerevisiae Y518 strain as a template, and use the following nucleotide sequences as primers to amplify the γ-glutamylcysteine synthetase gene:

[0067] Primer 1: 5'-ATGGGACTCTTAGCTTTGG-3'

[0068] Primer 2: 5'-TTAACATTTGCTTTCTATTGAAG-3'

[0069]PCR reaction conditions: 95°C for 5min, one cycle; 95°C for 30s, 60°C for 30s, 72°C for 2min, 35 cycles; finally 72°C for 10min.

[0070] The PCR product was recovered and ligated with the pMD18-T vector (purchased from TAKARA Company) to obtain the recombinant plasmid vector pMD18-T-gsh1. The recombinan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com