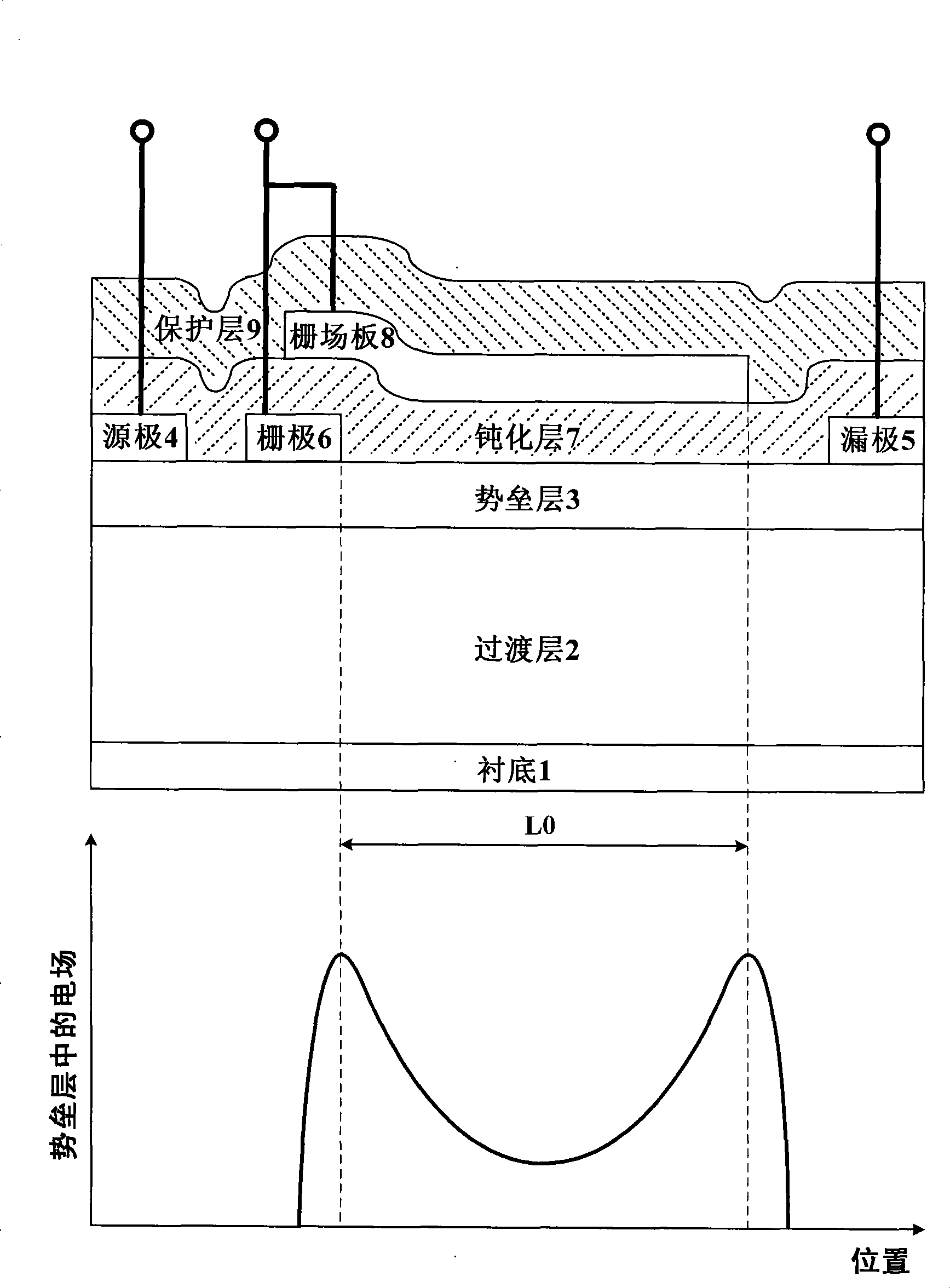

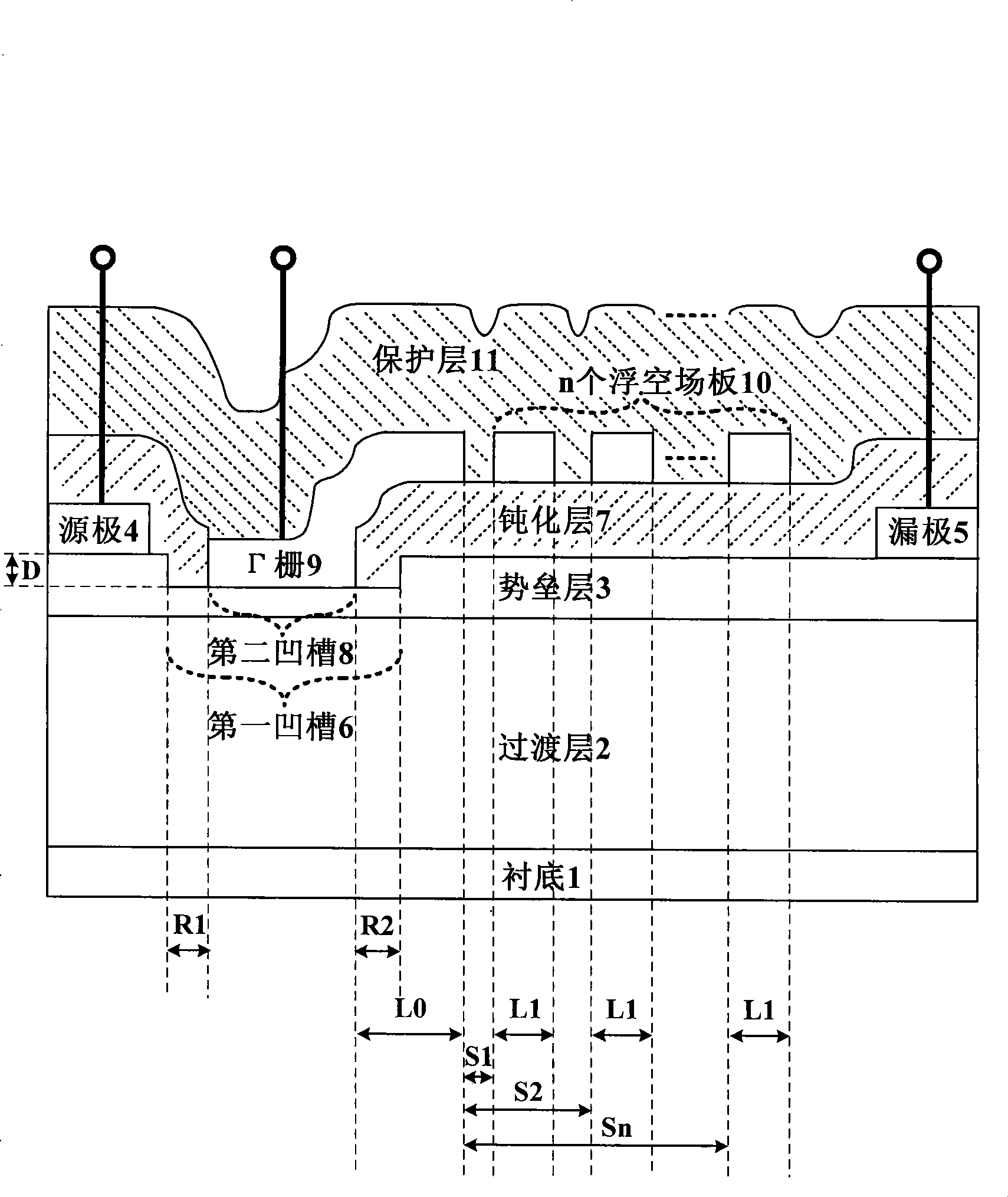

Groove Gamma gate transistor with high electron mobility and preparing method thereof

A high electron mobility, transistor technology, applied in the field of microelectronics, can solve the problems of weakening device input and output isolation, reducing device yield, reducing device stability, etc., to reduce gate leakage current and improve breakdown voltage , the effect of large drain-source voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

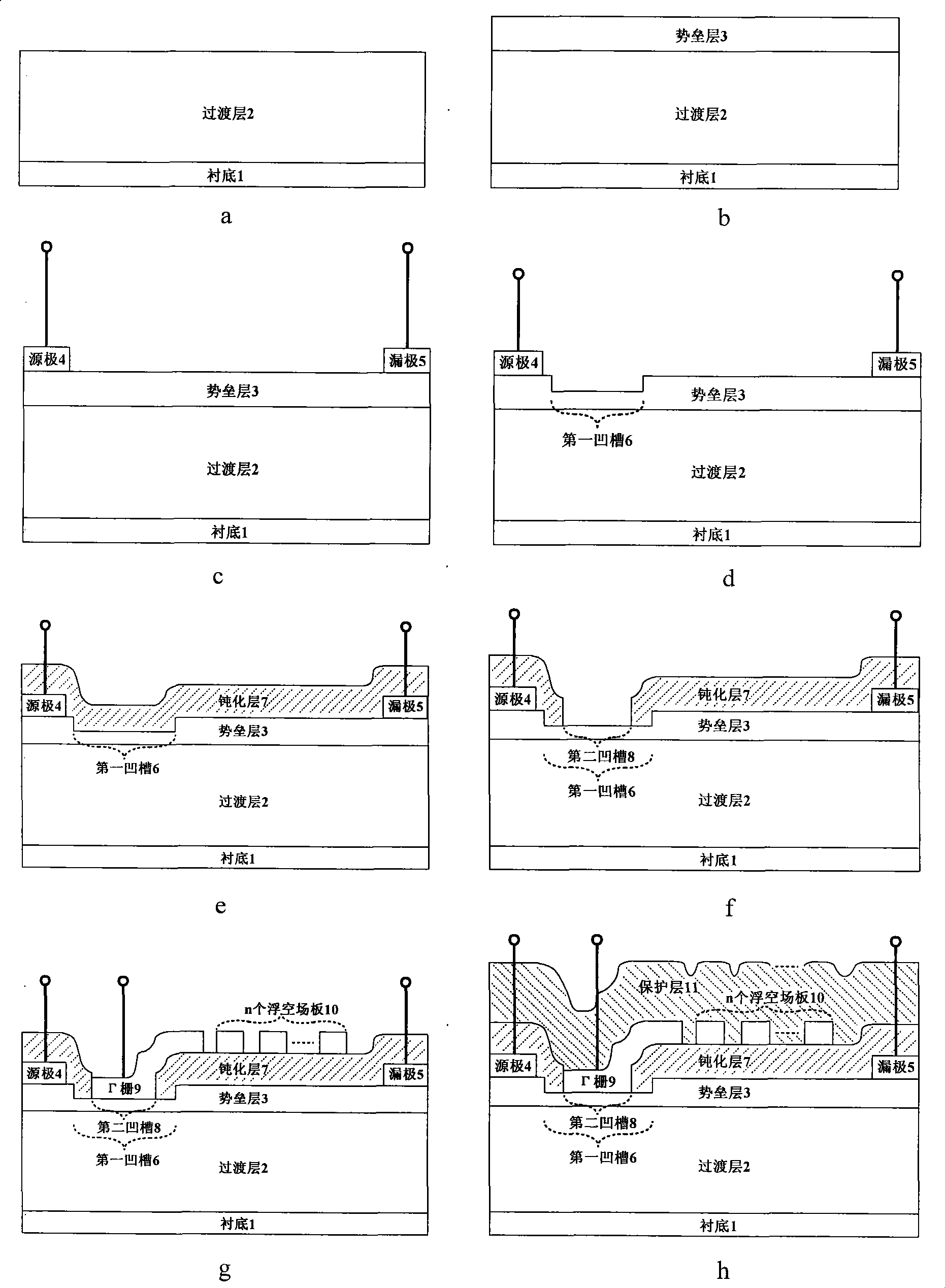

[0053] The production substrate is sapphire, and the passivation layer is SiO 2 , the protective layer is SiO 2 , the Γ gate and each floating field plate is a grooved Γ gate high electron mobility transistor composed of Mo / Au metal, and the process is:

[0054] 1. Using metal organic chemical vapor deposition technology to epitaxially undoped transition layer 2 with a thickness of 1 μm on the sapphire substrate 1, the transition layer is composed of AlN material with a thickness of 45 nm and GaN material with a thickness of 0.955 μm from bottom to top constitute. The process conditions used for the epitaxial lower layer AlN material are: temperature 610°C, pressure 186 Torr, hydrogen gas flow rate 5000 sccm, ammonia gas flow rate 5000 sccm, aluminum source flow rate 45 μmol / min; the process conditions for the epitaxial upper layer GaN material are: the temperature is 1080°C, pressure 186 Torr, hydrogen gas flow rate 5000 sccm, ammonia gas flow rate 5000 sccm, gallium source...

Embodiment 2

[0063] The substrate is made of silicon carbide, the passivation layer is SiN, the protective layer is SiN, the Γ gate and each floating field plate are Ni / Au metal combination grooved Γ gate high electron mobility transistors, and the process is:

[0064] 1. An undoped transition layer 2 with a thickness of 1.7 μm is epitaxially formed on a silicon carbide substrate 1 by metal-organic chemical vapor deposition technology. Made of GaN material. The process conditions used for the epitaxial lower layer AlN material are: temperature 1050°C, pressure 190 Torr, hydrogen gas flow rate 5100 sccm, ammonia gas flow rate 5100 sccm, aluminum source flow rate 18 μmol / min; the process conditions for the epitaxial upper layer GaN material are: temperature 1050°C, pressure 190 Torr, hydrogen gas flow rate 5100 sccm, ammonia gas flow rate 5100 sccm, gallium source flow rate 190 μmol / min.

[0065] 2. Deposit an undoped barrier layer 3 with a thickness of 29nm on the GaN transition layer 2 by...

Embodiment 3

[0073] The production substrate is silicon, the passivation layer is SiN, and the protective layer is Al 2 o 3 , the Γ gate and each floating field plate are Pt / Au metal combined groove Γ gate high electron mobility transistors, and the process is:

[0074] 1. Using metal organic chemical vapor deposition technology to epitaxially undoped transition layer 2 with a thickness of 5 μm on the silicon substrate 1, the transition layer is composed of AlN material with a thickness of 140 nm and GaN material with a thickness of 4.86 μm from bottom to top constitute. The process conditions used for the epitaxial lower layer AlN material are: temperature 890 °C, pressure 193 Torr, hydrogen gas flow rate 5200 sccm, ammonia gas flow rate 5200 sccm, aluminum source flow rate 45 μmol / min; the process conditions used for the epitaxial upper layer GaN material are: temperature 1080°C, pressure 193 Torr, hydrogen flow rate 5200 sccm, ammonia gas flow rate 5200 sccm, gallium source flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com