Method for improving brightness of attapulgite

A technology of attapulgite and nano-attapulgite, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as high product cost, environmental pollution, and inability to prepare rutile titanium dioxide, and achieve safety High, wide application field, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

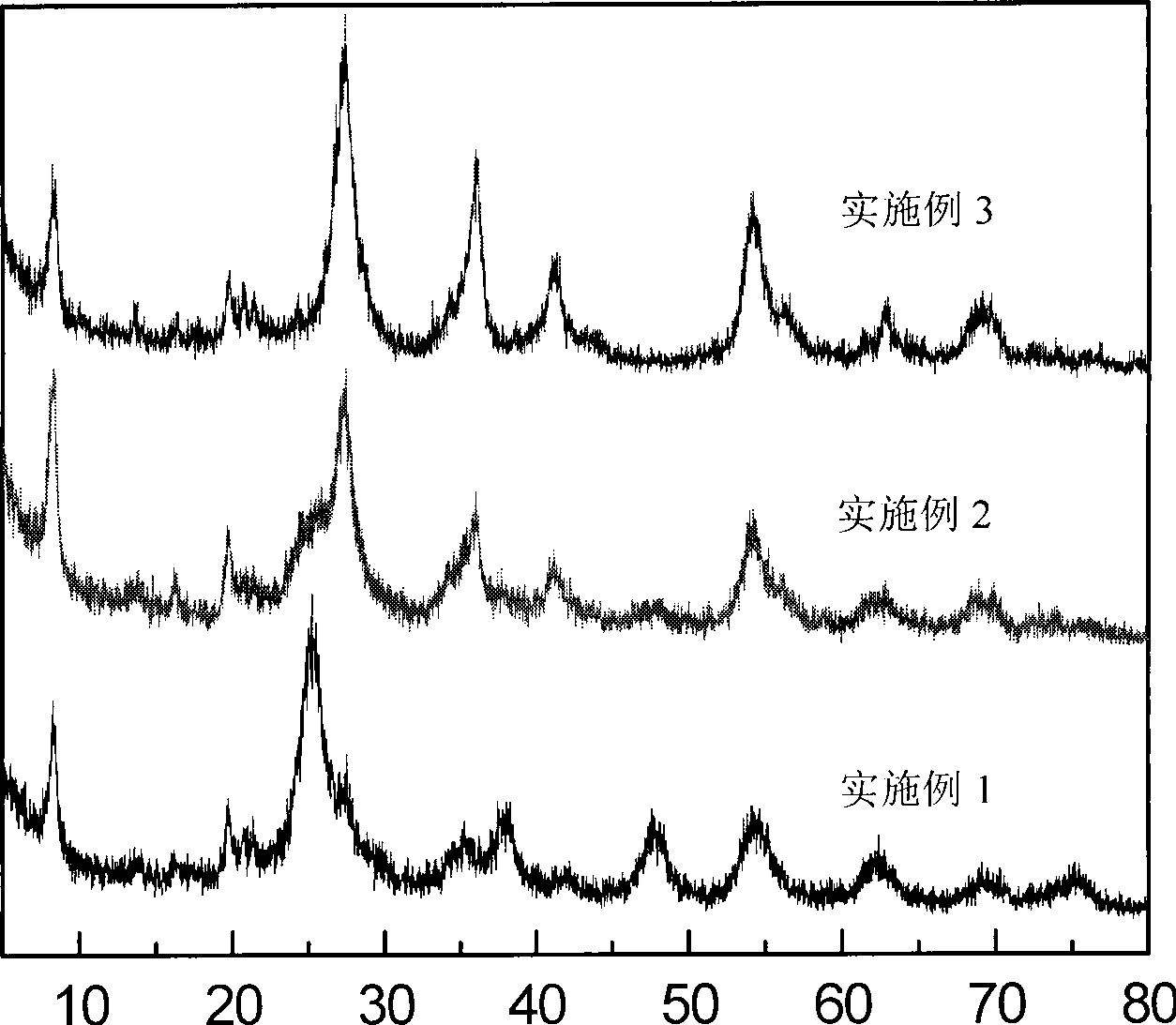

Examples

preparation example Construction

[0019] In the invention, firstly, the attapulgite is dispersed in the water phase to prepare the nano attapulgite aqueous dispersion. Then titanium tetrachloride (TiCl 4 ) as a raw material to prepare nano-titanium dioxide aggregates with high hiding power, and compound the nano-titanium dioxide aggregates with nano-attapulgite. The hydrochloric acid produced by the hydrolysis of titanium tetrachloride in the reaction process is used to dissolve the iron element in the attapulgite, and then sodium oxalate is used to complex and remove iron, so that chemical iron removal and surface chemical compounding have a synergistic effect to jointly improve the unevenness The purpose of stick clay whiteness. The concrete steps of above-mentioned preparation method are as follows:

[0020] 1. For methods of dispersing and purifying attapulgite and preparing nano-attapulgite water dispersion, please refer to US Patents US6130179, US6444601 and Chinese Patents CN1248984C, CN101224892A, CN...

Embodiment 1

[0028] Add attapulgite with a whiteness of 65 to deionized water, add sodium hexametaphosphate accounting for 3% of the mass of attapulgite, and stir at high speed for 2 hours with an ME-100 emulsifier (produced by Sino-US joint venture Nantong Ross Mixing Equipment Co., Ltd.) , Stand still for 5 days (ie 120 hours). Impurities and undispersed attapulgite aggregates at the bottom of the deposition are removed to obtain a nano attapulgite aqueous dispersion with a mass ratio of m (attapulgite):m (water)=1:10. Measure 75mL of 1mol / L NaOH solution into a 2000mL three-necked flask, and slowly add 1mol / L TiCl dropwise while stirring 4 Aqueous solution 75mL, control the reaction temperature at 10°C. TiCl 4 After the aqueous solution was added dropwise, the temperature was raised to 85°C, and 1320g of nano-attapulgite aqueous dispersion was added into a three-necked flask, stirred and kept at 85°C for 2 hours, then suction filtered and washed until the pH of the filtrate = 1.0, and...

Embodiment 2

[0030] Add attapulgite with a whiteness of 65 into deionized water, add sodium pyrophosphate accounting for 2% of the mass of attapulgite, and stir at a high speed for 2 hours with an ME-100 emulsifier (produced by Sino-US joint venture Nantong Ross Mixing Equipment Co., Ltd.), Stand for 5 days (120h). Impurities at the bottom of the deposition and undispersed attapulgite aggregates are removed to obtain a nano attapulgite aqueous dispersion with a mass ratio of m(attapulgite):m(water)=1:10. Measure 150mL of 1.5mol / L ammonia solution into a 2000mL three-necked flask, and slowly add 3mol / L TiCl dropwise while stirring 4 Aqueous solution 75mL, control the reaction temperature at 30°C. TiCl 4 After the aqueous solution was added dropwise, the temperature was raised to 80°C, and 1320g of nano-attapulgite aqueous dispersion was added into a three-necked flask, stirred and kept at 80°C for 2 hours, then suction filtered and washed until the pH of the filtrate = 1.0, and the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com