Flame-retardant acrylic fibre and preparation thereof

A flame retardant acrylic fiber and solution technology, applied in the field of flame retardant acrylic fiber, can solve the problems of difficult mass production, high operation level, inconvenient use, etc., and achieve the effects of easy industrial production, good flame retardant effect and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

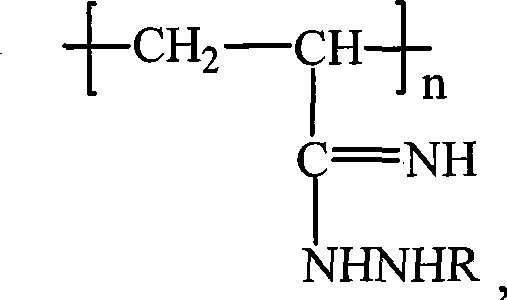

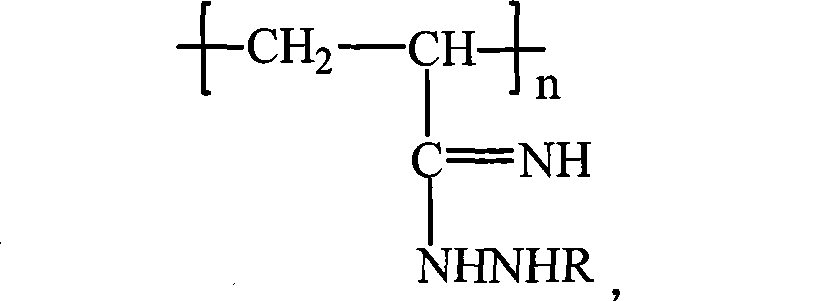

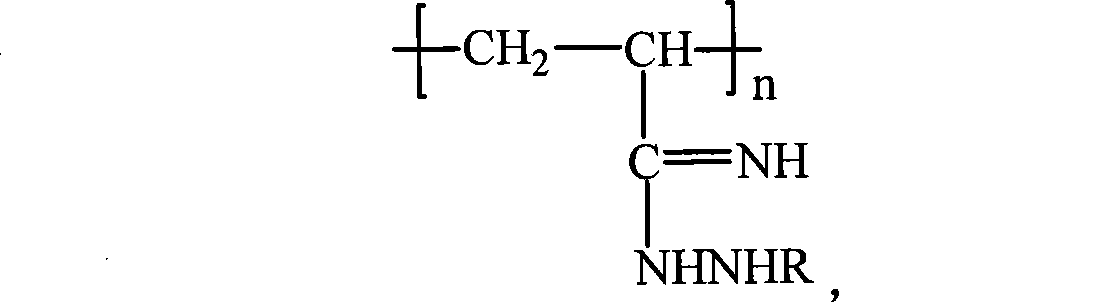

Image

Examples

preparation example Construction

[0020] The preparation method of the hydrazine compound is not complicated. For example, the preparation of thiophosphoryl trihydrazide is to add phosphorus trichloride and hydrazine hydrate in a three-necked flask at a molar ratio of 1:3, and simultaneously add Triethylamine with the same mole of sulfur as phosphorus, magnetically stirred, controlled temperature at 0-5°C, stopped the reaction after 4 hours of reaction, filtered to remove triethylamine hydrochloride, and obtained thiophosphoryl trihydrazine flame retardant, yield 82-76%; Another example, to prepare acryloyl hydrazide, is to add acryloyl chloride and hydrazine hydrate into a three-necked flask with a molar ratio of 1:1, and at the same time add triethylamine with the same mole as acryloyl chloride, and magnetically stir. The temperature was controlled at 0° C., the reaction was stopped after 4 hours of reaction, and the triethylamine hydrochloride was removed by filtration to obtain the acrylohydrazide flame ret...

Embodiment 1

[0027] Preparation of flame retardant acrylic fibers.

[0028] First prepare thiophosphoryl trihydrazide: add phosphorous trichloride and hydrazine hydrate into a three-necked flask at a molar ratio of 1:3, and at the same time add triethylamine with the same mole as phosphorous trichloride, stir magnetically, and control The temperature was 0° C., the reaction was stopped after 4 hours of reaction, and the triethylamine hydrochloride was removed by filtration to obtain a thiophosphoryl trihydrazide flame retardant with a yield of 82%.

[0029] Then, the conventional acrylic fiber with a denier of 3.5dtex, a breaking strength of 3.3cN / dtex, a breaking elongation of 25%, and an LOI value of 18.2% was used as a raw material to prepare a flame-retardant acrylic fiber.

[0030] Add acrylic fiber and thiophosphoryl trihydrazide solution into a 250mL three-necked flask equipped with a mechanical stirrer at a mass ratio of 1:20, heat the thiophosphoryl trihydrazide solution to 100°C,...

Embodiment 2

[0037] Preparation of flame retardant acrylic fibers.

[0038]The reaction time of the acrylic fiber and thiophosphoryl trihydrazide in this embodiment is 40 minutes, the heating temperature of the thiophosphoryl trihydrazide solution is 95° C., and the mass ratio of the acrylic fiber to the phosphorotrihydrazide solution is 1:25. All the other preparation processes are the same as in Example 1.

[0039] After testing, the denier of the acrylic fiber is 3.5 dtex, the breaking strength is 3.0 cN / dtex, the breaking elongation is 22%, and the LOI value is 30.5%. Compared with Comparative Example 1, the flame-retardant acrylic fiber of this example does not contain halogen elements, and the LOI value is increased by 5.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com