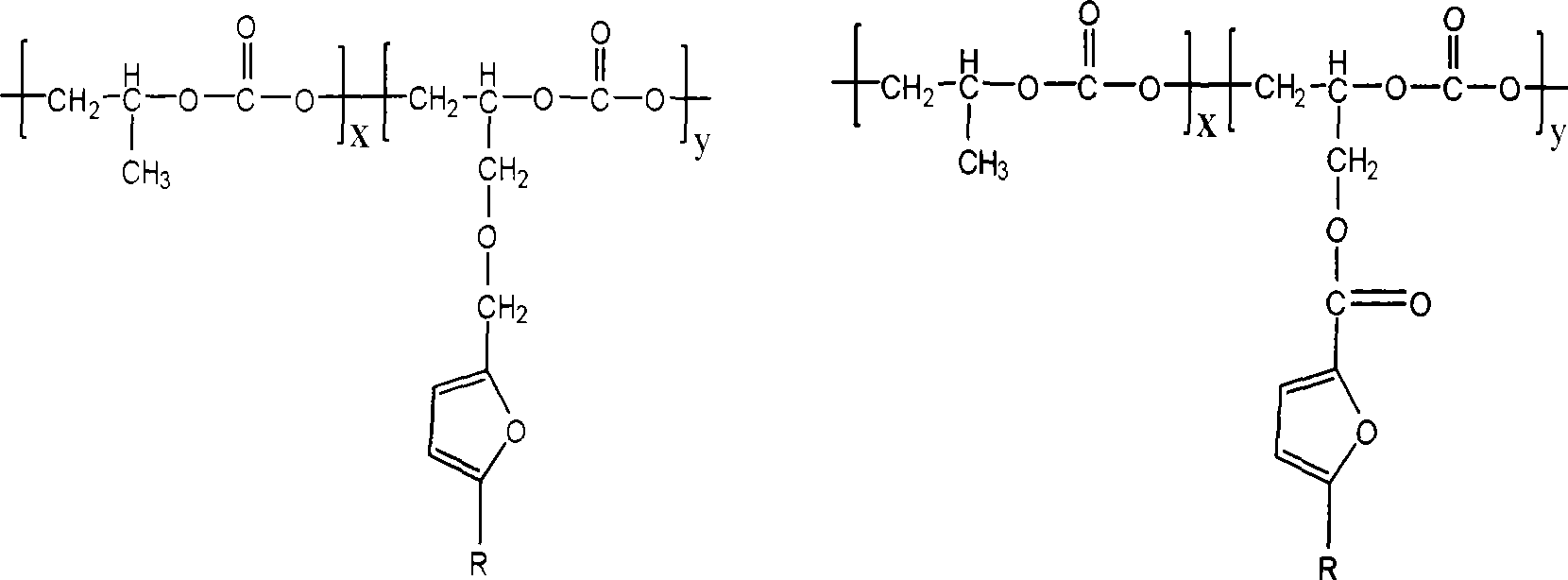

Furan glycidyl ether or ester-epoxypropane-CO2 copolymer and preparation thereof

A technology of glycidyl ether and glycidyl ester, which is applied in the field of furan glycidyl ether or ester-propylene oxide-carbon dioxide terpolymer and its preparation, can solve the problem of poor blending compatibility, affecting processing performance and application range , pollute the environment, end-capping agents and other issues, to achieve the effect of favorable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0033] at a purity of 99.99% N 2 Add 0.0004885mol Y (CCl 3 COO) 3 , 20ml1, 3-dioxolane and 0.004885mol glycerol, to be Y (CCl 3 COO) 3 After all dissolved, slowly add 0.00977mol ZnEt dropwise to the preparation bottle 2 , ZnEt 2 It is advisable to control the reaction temperature at 35-45°C for the dropping speed. ZnEt 2 After the dropwise addition, after no gas is released, place the preparation bottle in a constant temperature bath for aging. The aging conditions are: the temperature of the constant temperature bath is 60°C; the frequency of mechanical oscillation is 150 times / min; the amplitude is 40mm; A total of 2 hours was carried out to obtain a white suspension liquid which was a rare earth three-way catalyst.

preparation Embodiment 2

[0035] The synthesis of furyl methyl glycidyl ether, in the there-necked flask equipped with electric stirrer, thermometer and constant pressure dropping funnel, add 7.6mol epichlorohydrin, 800mL sodium hydroxide solution (50%w / w), and 0.076mol tetra-tert-butylammonium bisulfate, and then 3.8mol of purified furanmethanol was dropped into the above-mentioned three-necked flask at a rate of 6mL / min under a constant pressure dropping funnel under strong stirring at 400rpm, and the temperature of the control system did not exceed 20°C , After reacting for 4 hours, the reaction solution was washed with distilled water until neutral, and the obtained organic phase was dried for 24 hours with 60 g of anhydrous magnesium sulfate, and the dried organic phase was filtered to remove anhydrous magnesium sulfate. The obtained organic phase was distilled off under reduced pressure (2.0KPa) to remove unreacted epichlorohydrin to obtain a crude product of furyl methyl glycidyl ether. The crud...

preparation Embodiment 3

[0037] Synthesis of Glycidyl Tetrahydrofurancarboxylate

[0038] 1) Synthesis of sodium tetrahydrofuran formate, 1.0 mol of sodium hydroxide and 50 ml of distilled water were added into a three-necked flask, then 1.1 mol of tetrahydrofuran formic acid and 80 mL of ethanol (99.5% in purity) were mixed with 6 mL of tetrahydrofuran formic acid through a constant pressure dropping funnel under vigorous stirring at 450 rpm. Drop it into the above-mentioned three-necked flask at a rate of 1 / min, control the temperature of the system at 25°C, and react for 4 hours, distill off ethanol and water under reduced pressure (2.0KPa), wash with acetone three times, each time with 100mL of acetone, at 70°C Dry in vacuo to constant weight. Sodium tetrahydrofuran formate was obtained.

[0039] 2) Synthesis of glycidyl tetrahydrofuran formate, 1.0mol sodium tetrahydrofuran formate, 5.0mol epichlorohydrin, 0.015mol tetra-tert-butylammonium bisulfate are added in a three-necked flask equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com