Method for preparing polymer solar battery

A technology of solar cells and polymers, which is applied in the field of polymer solar cells and can solve the problems of low charge collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The operation of the first three steps is the same as the processing method of the prior art, and the fourth step is:

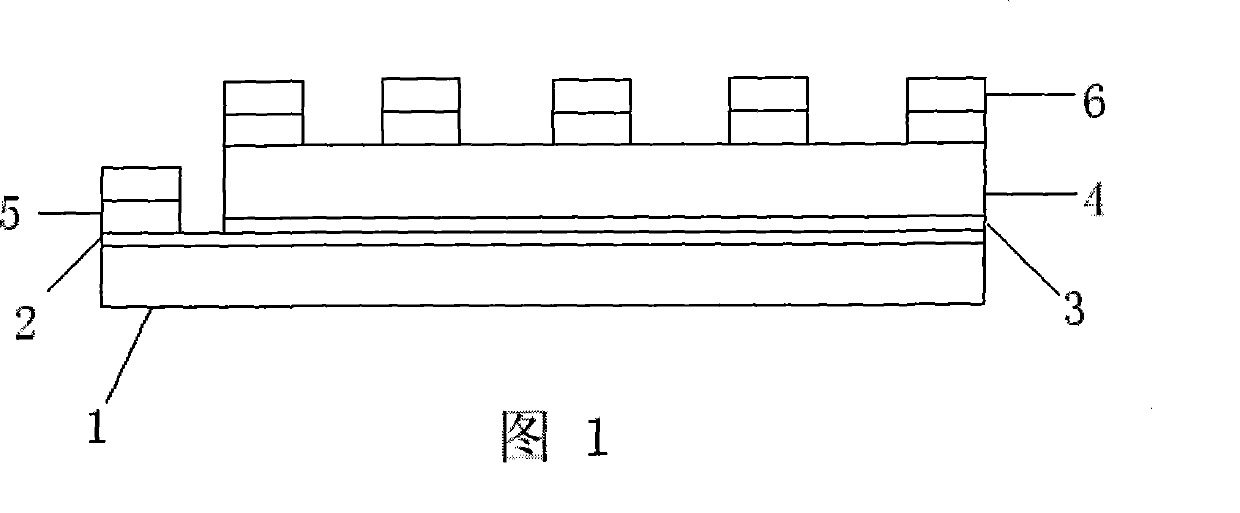

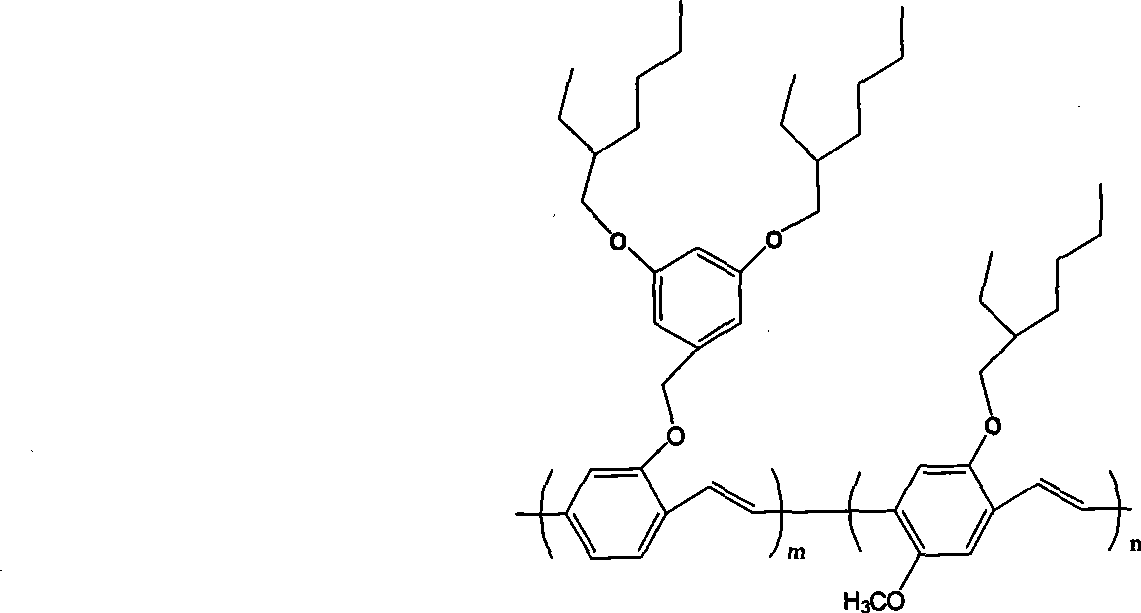

[0025] 4) Put the polymer solar cell device whose active layer has been heated and annealed into a vacuum coating machine for evaporation. When the vacuum degree is higher than 1×10 -4 Start to evaporate LiF at Pa, and control the evaporation rate of LiF by adjusting the heating current on the film thickness monitor. The LiF evaporation rate is 1-2 The thickness is 1.5nm; finally the Al electrode is evaporated, the thickness is 150nm, and the effective area of the battery is 12mm 2 , the device structure is ITO / PEDOT:PSS(30nm) / electron donor polymer BEH-co-MEH-PPV:PCBM=1:3(200nm) / LiF(1.5nm) / Al(150nm) polymer Solar battery.

Embodiment 2

[0027] The operation of the first three steps is the same as the processing method of the prior art, and the fourth step is:

[0028] 4) Put the polymer solar cell device whose active layer has been heated and annealed into a vacuum coating machine for evaporation. When the vacuum degree is higher than 1×10 -4 Start to evaporate LiF at Pa, and control the evaporation rate of LiF by adjusting the heating current on the film thickness monitor. The LiF evaporation rate is 1-2 The thickness is 1.2nm; finally the Al electrode is evaporated, the thickness is 150nm, and the effective area of the battery is 12mm 2 , the device structure is ITO / PEDOT:PSS(30nm) / electron donor polymer BEH-co-MEH-PPV:PCBM=1:3(200nm) / LiF(1.2nm) / Al(150nm) polymer Solar battery.

Embodiment 3

[0030] The operation of the first three steps is the same as the processing method of the prior art, and the fourth step is:

[0031] 4) Put the polymer solar cell device whose active layer has been heated and annealed into a vacuum coating machine for evaporation. When the vacuum degree is higher than 1×10 -4 Start to evaporate LiF at Pa, and control the evaporation rate of LiF by adjusting the heating current on the film thickness monitor. The LiF evaporation rate is 1-2 The thickness is 1nm; finally the Al electrode is evaporated, the thickness is 150nm, and the effective area of the battery is 12mm 2 , the device structure is ITO / PEDOT:PSS(30nm) / electron donor polymer BEH-co-MEH-PPV:PCBM=1:3(200nm) / LiF(1.0nm) / Al(150nm) polymer Solar battery.

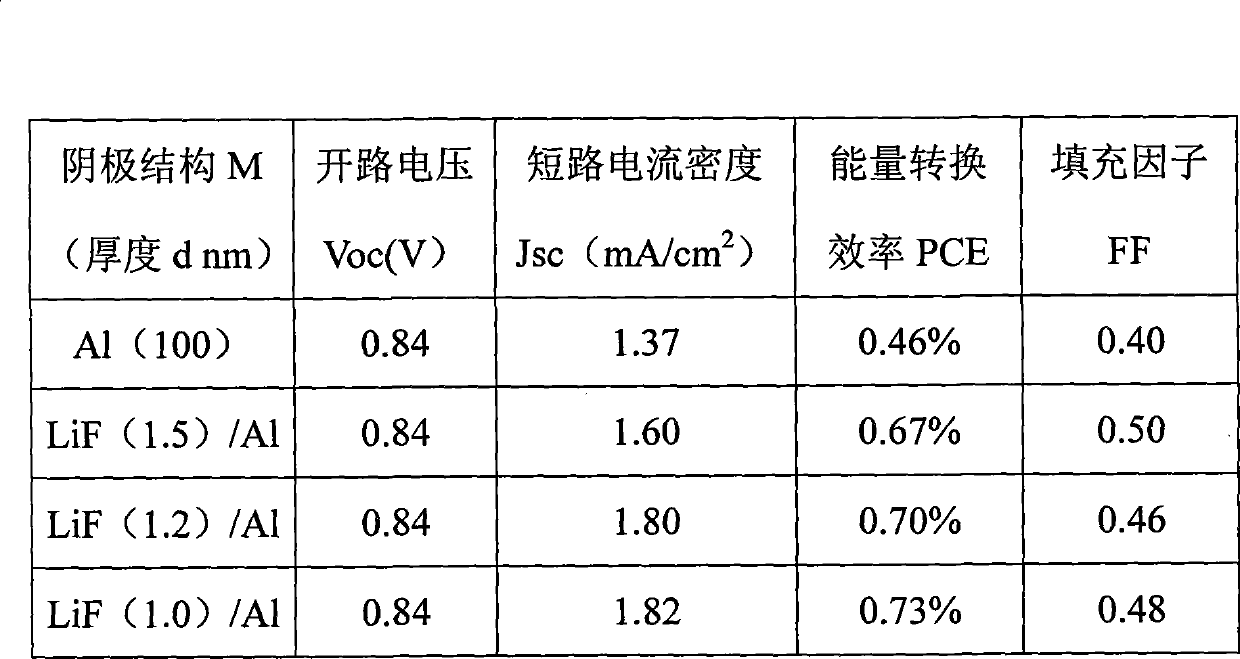

[0032] With halogen lamp as light source, at 100mW / cm 2 Under the light intensity, the performance of the polymer thin film solar cell prepared by the method of the present invention was tested, including open circuit voltage, sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com