Novel technique for producing sulfur from industrial waste gypsum

A technology of industrial waste gypsum and gypsum production, which is applied in the preparation/purification of sulfur, cement production, etc., can solve the problems of small investment, complicated equipment, waste of resources, etc., achieve significant social and economic benefits, and facilitate environmental protection standards and protection environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

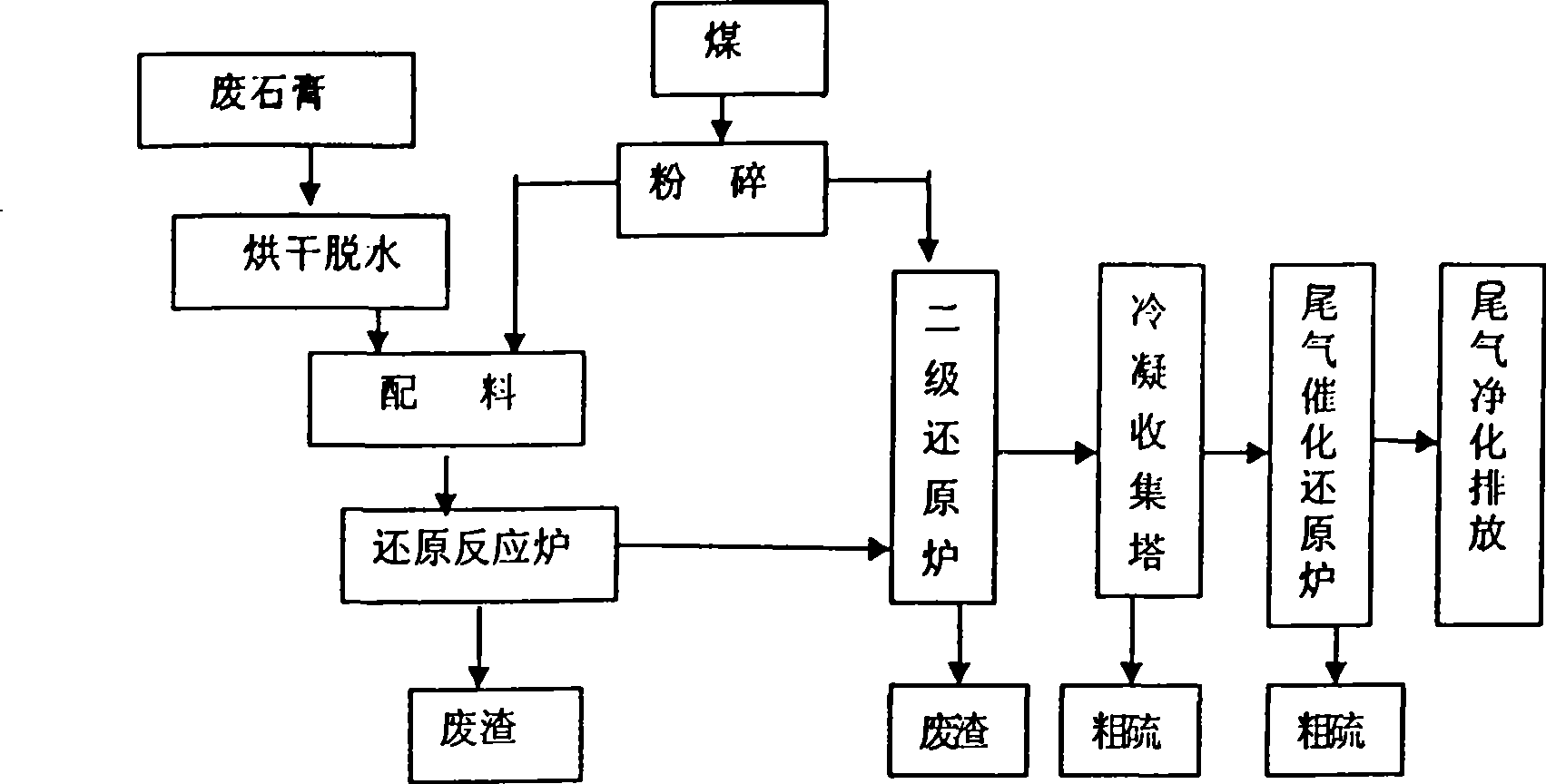

Embodiment 1

[0024] Desulfurization gypsum and high-sulfur coal from a certain place are used as raw materials and fuels. The desulfurization gypsum is a light yellow powder with a moisture content of 12.1% and a dry basis of SO 3 The content is 44.3%, the low calorific value of high-sulfur coal is 4875×4.18KJ / kg, the total sulfur content is 6.3%, and the high-sulfur coal has been pulverized. The total material consumption ratio of desulfurized gypsum and coal is 30:70. The desulfurized gypsum is dried and dehydrated and put into the roasting reduction furnace together with crushed coal. The temperature in the furnace is 900°C, rich in steam S, SO 2 , CO, CO 2 , N 2 The high-temperature gas is sent to the secondary reduction furnace, and the high-sulfur coal is still used as the reducing agent. The reduction temperature is 1000 ° C. The gas rich in S steam from the secondary reduction furnace is sent to the condensation collection tower, and the tail gas enters the low-temperature cataly...

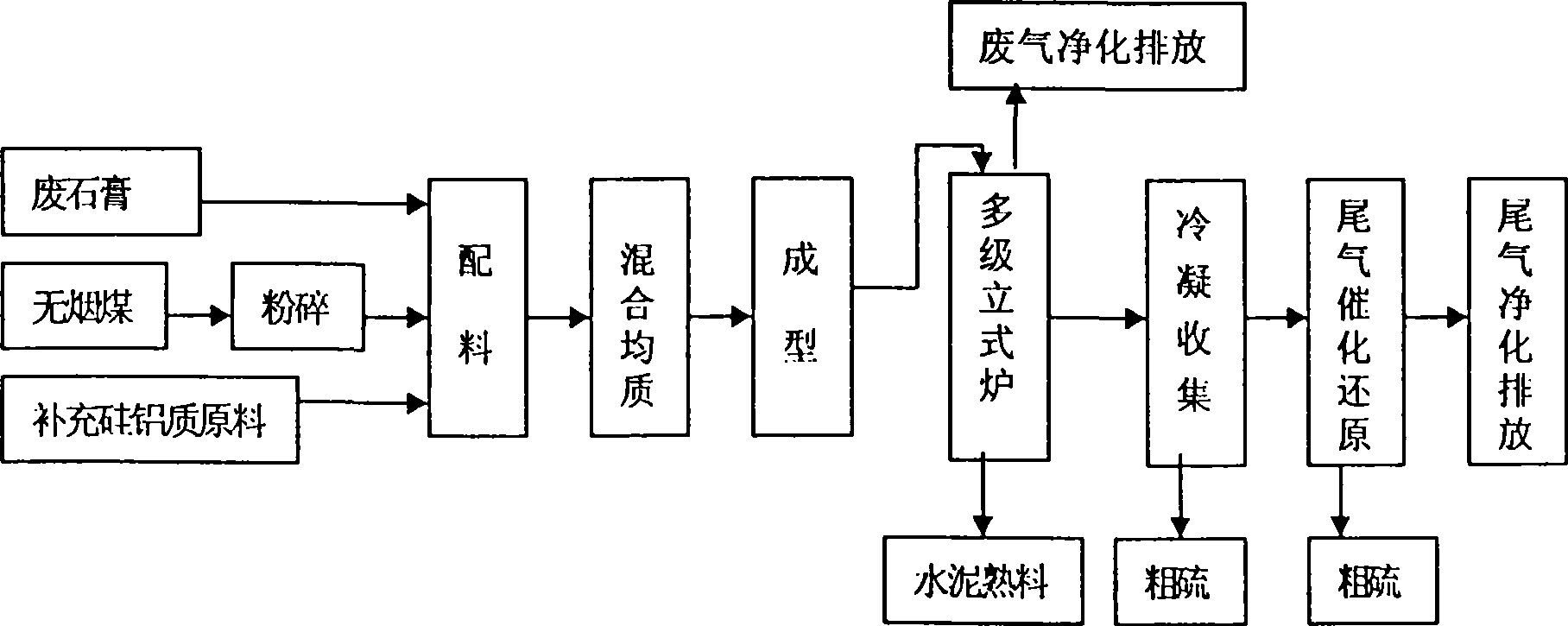

Embodiment 2

[0026] Use the waste gypsum and anthracite produced by titanium dioxide in a certain place, the water content of waste gypsum is 37%, and the dry basis is SO 3 The content is 38.6%, the calorific value of anthracite is 5543×4.18KJ / kg, the total sulfur content is 1.2%, and the sulfur by-product cement clinker is produced by combined vertical furnace reduction treatment. Grind the supplemented silicon-aluminum raw materials and anthracite powder to a dry powder with a fineness of 80um and a sieve residue <14%. Mix the dry powder and wet waste gypsum ingredients evenly, and shape it into a Φ12mm rod. The ash content of the rod is controlled at KH1 .0, N2.2, P1.5; the material ratio of waste gypsum to coal is 80:20. The material rods are continuously added to the vertical furnace from the upper part of the combined vertical furnace. The drying and dehydration of the material rods is solved by a special heating system. The drying and dehydration waste gas is purified and discharged...

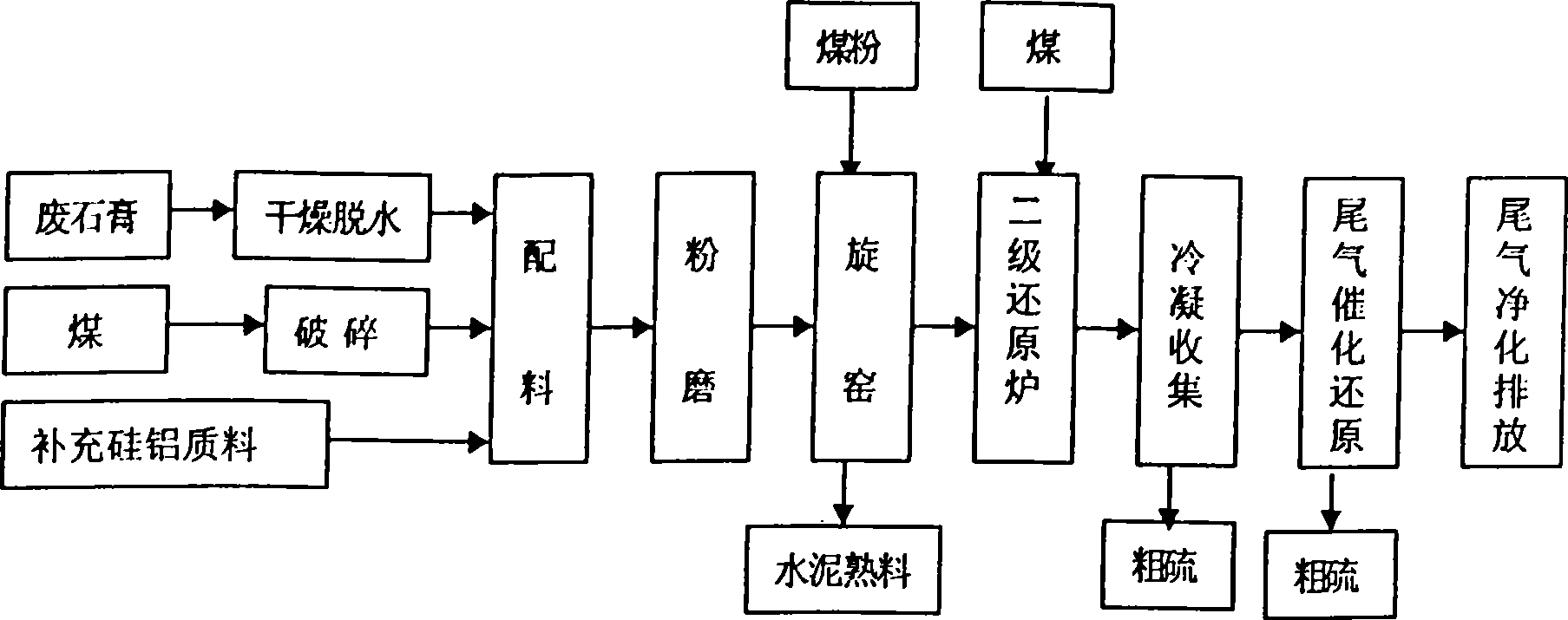

Embodiment 3

[0028] Use a citric acid waste residue—lemon gypsum, gray odorous wet material, moisture content 32.7%, dry basis SO 3 The content is 42.6%, anthracite is used as thermal reducing agent, and the calorific value of coal is 4987×4.18KJ / kg. The combined vertical reduction reaction furnace is used to produce sulfur and produce cement clinker at the same time. Firstly, the crushed coal and supplemented shale and cinder ingredients are ground into dry powder with 80um sieve ≤ 12%, and then the dry powder and wet lemon gypsum ingredients are mixed homogeneously and formed into Φ12mm rods. The material consumption ratio of waste gypsum to coal 55:45, the clinker rate is designed as KH 0.95, h 1.80, P 2.4; material rods are added from the upper part of the combined furnace, heated by a special heat source for drying and dehydration, and the dried and dehydrated material rods enter the middle and lower part for high-temperature reduction reaction The heat source is provided by the coal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com