Polymer body heterojunction solar cell and preparation thereof

A bulk heterojunction and solar cell technology, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve problems such as bandgap widening and matching degree reduction, and achieve improved performance, low production cost, and high production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

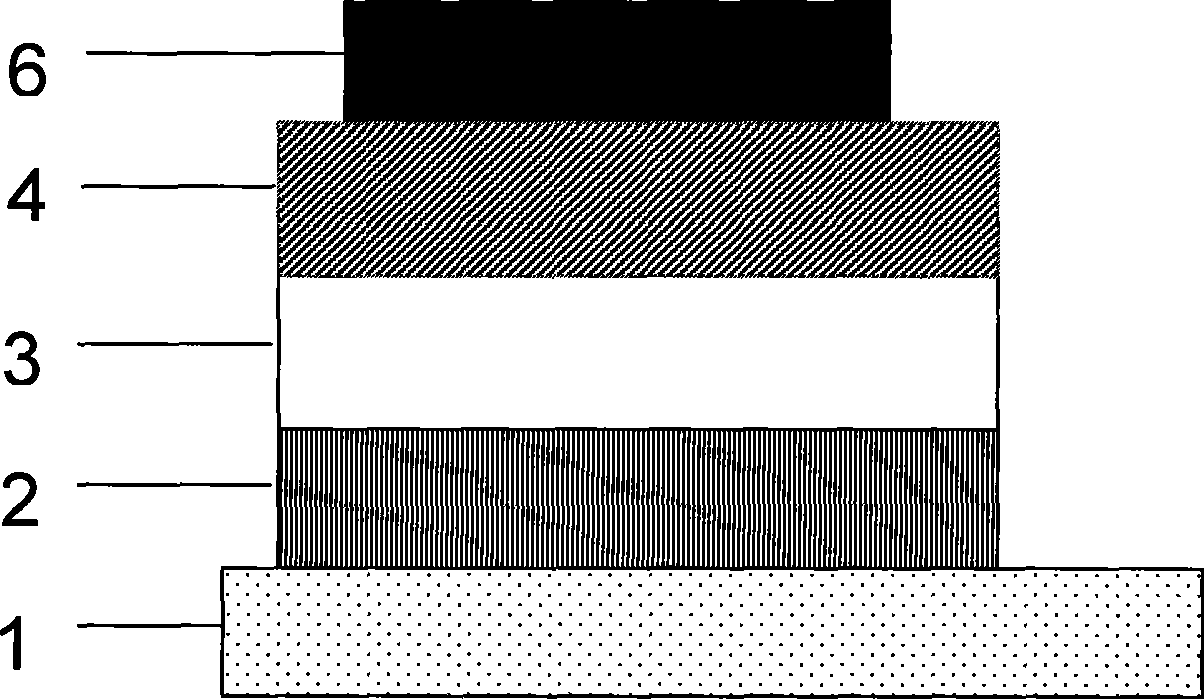

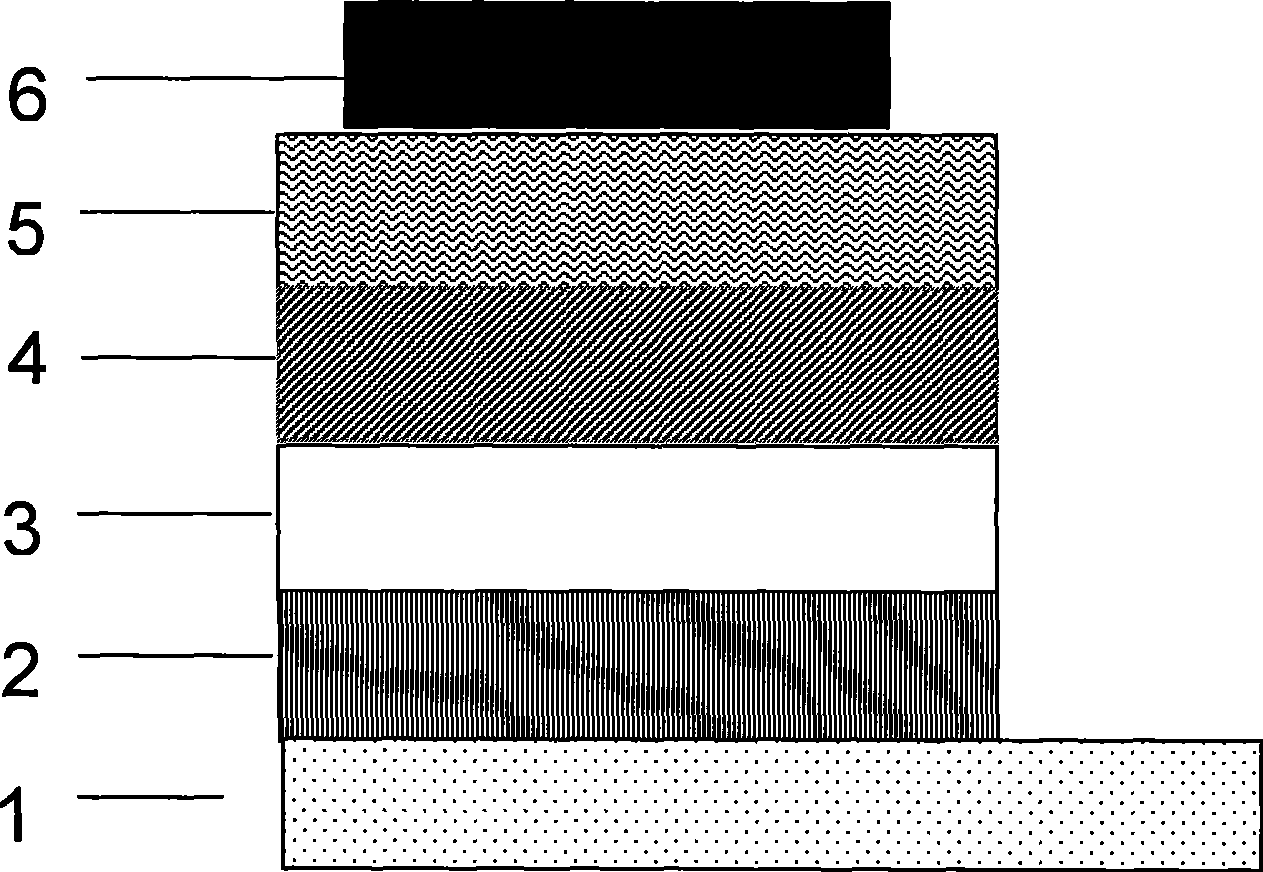

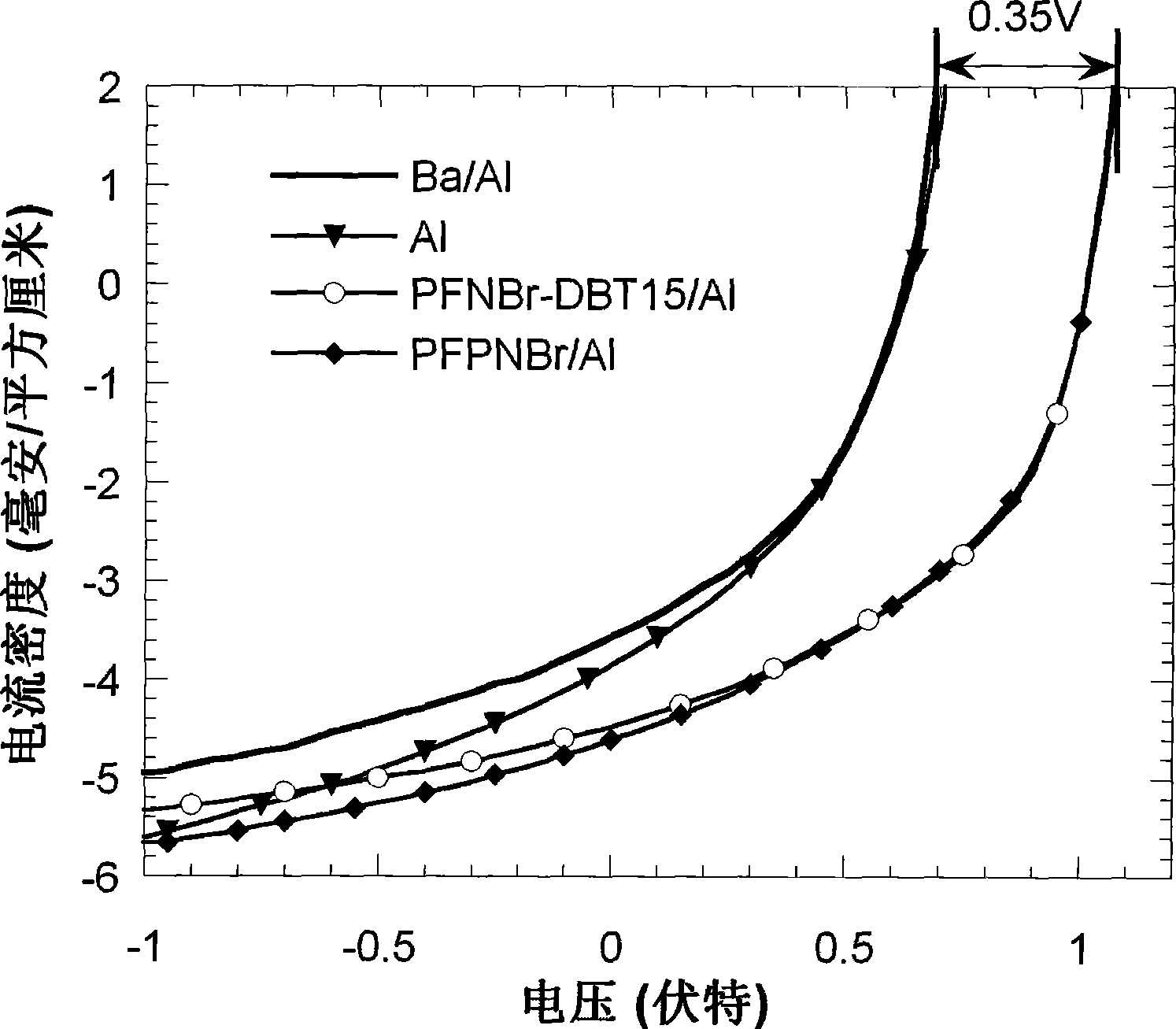

[0057] select figure 2 The structure of the polymer bulk heterojunction solar cell device shown is poly[2,7-(9,9-dioctyl)fluorene-9,9-(bis(3'-(N,N-dimethyl )-N-ethylammonium)propyl)fluorene dibromide-4,7-dithiophen-2-yl-2,1,3-benzothiadiazole] (PFNBr-DBT15) as the cathode interface layer, fluorene and 4,7-dithiophen-2-yl-2,1,3-benzothiadiazole copolymer poly[2,7-(9,9-dioctyl)fluorene-copolymerization-4,7-dithiophene —2-base-2,1,3-benzothiadiazole] (PFO-DBT35) is used as polymer electron donor material, PCBM is electron acceptor material, and whether there is a cathode interface layer has a great influence on the polymer bulk heterojunction solar energy. The impact on the performance of the battery device is shown in Table 2.

[0058] It can be seen from this that the polymer bulk heterojunction solar cell with PFNBr-DBT15 as the interface layer, compared with conventional devices, its open circuit voltage is greatly increased from 0.60-0.75 volts to 0.90-1.00 volts (such as...

Embodiment 2

[0062] Repeat Example 1, select poly[9,9-dioctylfluorene-9,9-bis(N,N-dimethylaminopropyl) fluorene-4,7-dithiophene-2-yl-2,1 , 3-benzothiadiazole] (PFN-DBT15) as the cathode interface layer, other conditions remain unchanged. The experimental results are summarized in Table 3.

[0063] table 3

[0064]

[0065] As can be seen from Table 3, poly[9,9-dioctylfluorene-9,9-bis(N,N-dimethylaminopropyl)fluorene-4,7-dithiophen-2-yl-2, 1,3-Benzothiadiazole (PFN-DBT15) is used as the cathode interface layer of polymer bulk heterojunction solar cells. Compared with conventional devices, the open circuit voltage is greatly increased from 0.60-0.75 volts to 0.85 volts.

Embodiment 3

[0067] Repeat Example 1, select poly[2,5-dioctyloxy-1,4-phenylene-2,5-(bis(3'-(N,N-dimethyl)-N-ethylammonium ) Propyl-1,4-phenylene] dibromide (PPPNBr) is used as the cathode interface layer, and other conditions are constant. The experimental results are summarized in Table 4.

[0068] Table 4

[0069]

[0070]

[0071] As can be seen from Table 4, poly[2,5-dioctyloxy-1,4-phenylene-2,5-(bis(3'-(N,N-dimethyl)-N-ethyl Ammonium) propyl-1,4-phenylene] dibromide (PPPNBr) as the cathode interface layer of polymer bulk heterojunction solar cells, compared with conventional devices, its open circuit voltage is greatly improved from 0.60-0.75 volts to 0.90-1.00 volts (as image 3 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com