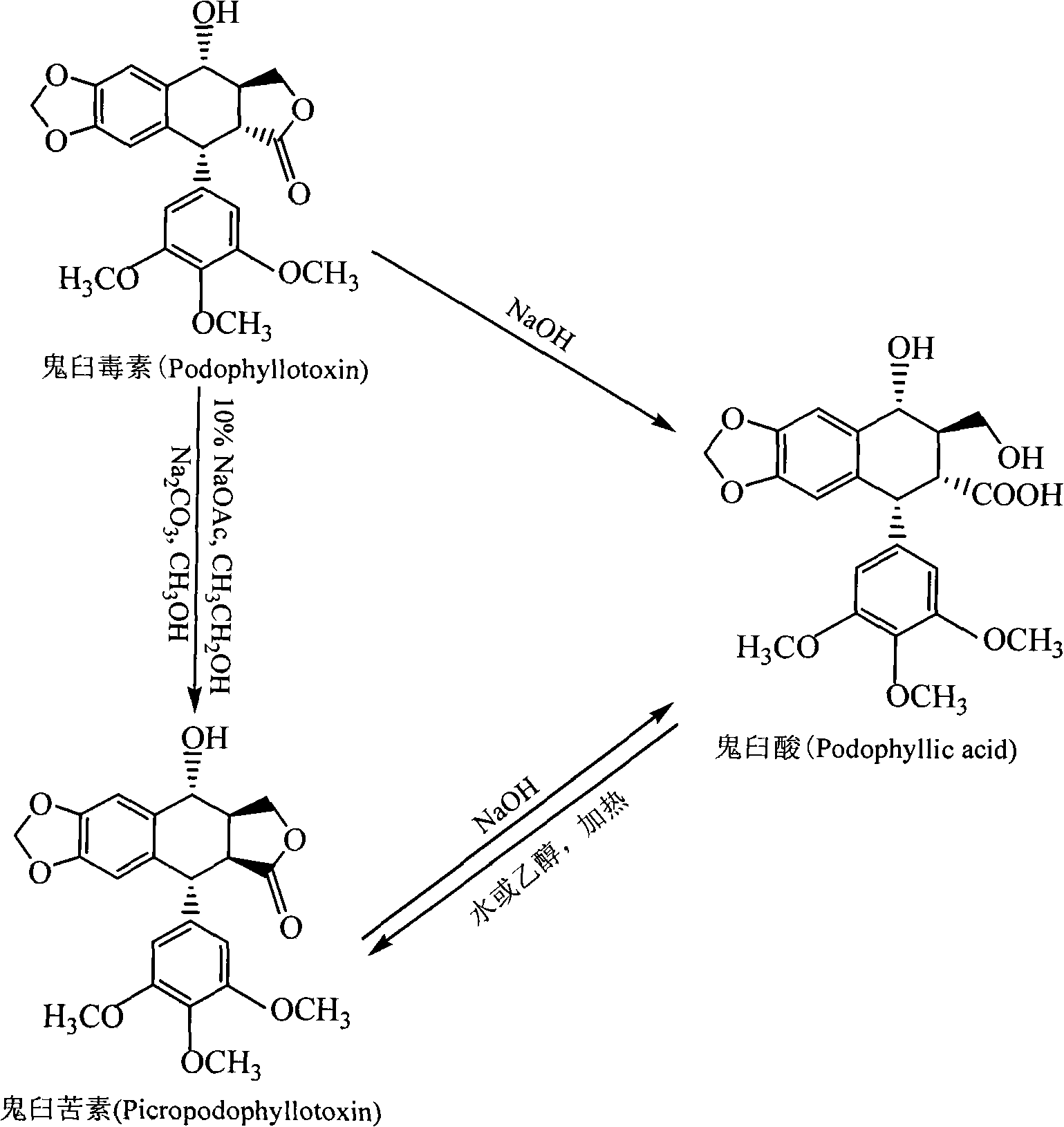

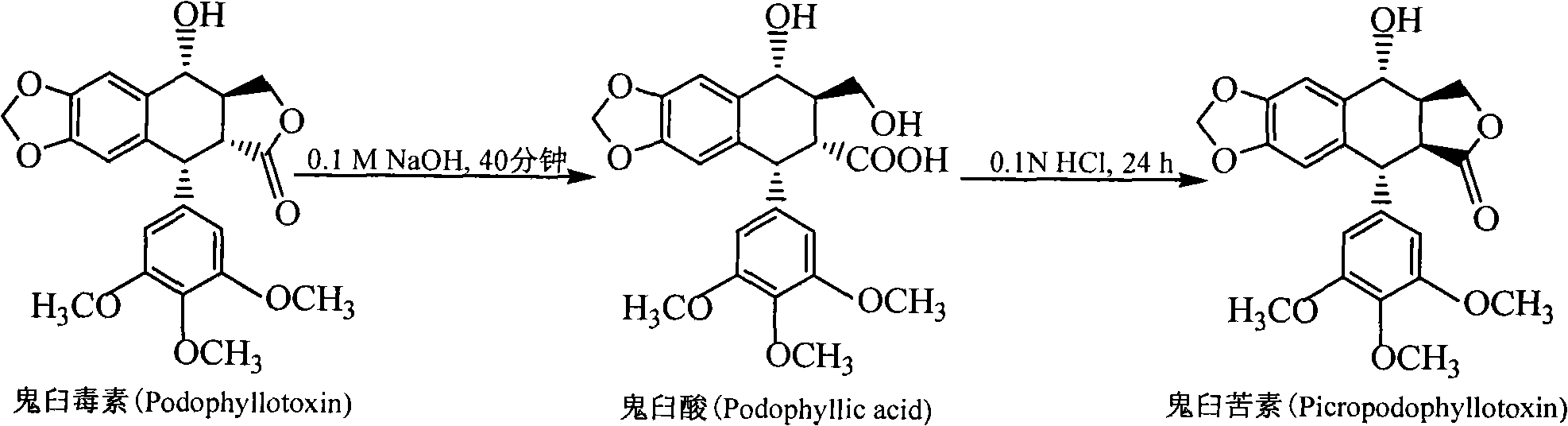

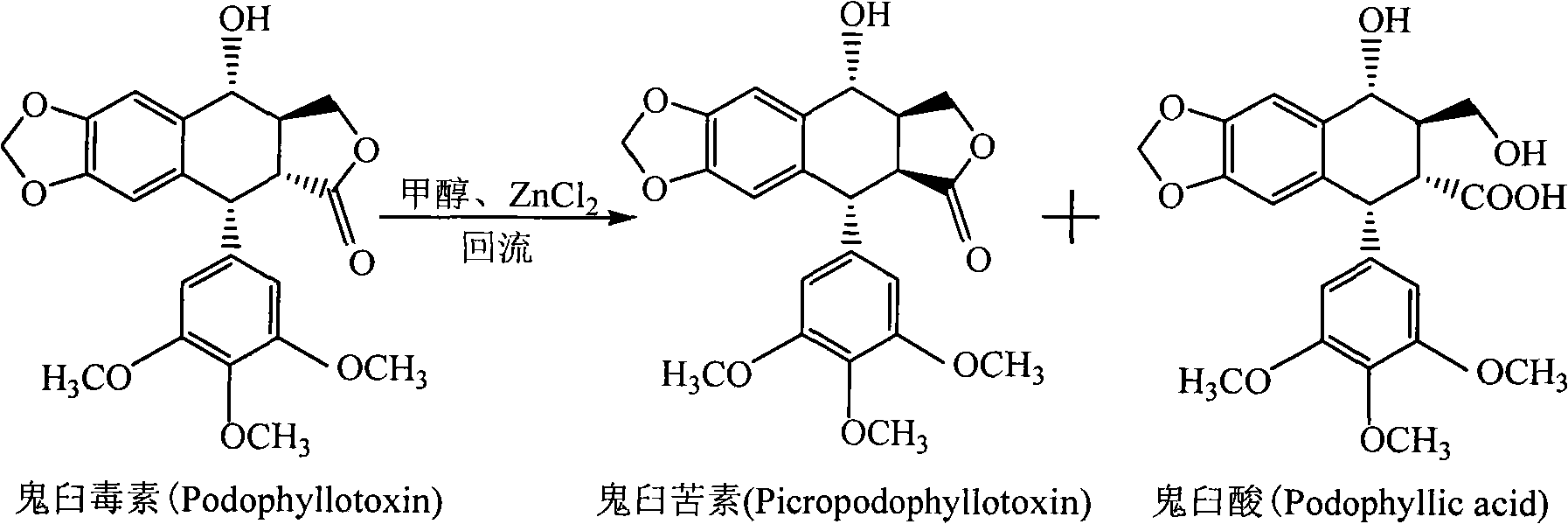

Method for converting podophyllinic acid lactone into podophyllic acid and picropodophyllin

A technology of podophyllotoxin and picropodophyllin, applied in biochemical equipment and methods, methods based on microorganisms, organic chemistry, etc., can solve the problems of easy pollution of the environment and low product yield, and achieve environmental friendliness and high product yield. The effect of high rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Culture of Pseudomonas aeruginosa:

[0057] Slope culture: medium: glucose 2%, beef extract 0.3%, peptone 0.5%, sodium chloride 0.5%, agar 2%, pH value 7, sterilized at 115 degrees Celsius for 30 minutes, cooled after sterilization, and made Inclined surface, inoculated with Pseudomonas aeruginosa strains, cultured at 37 degrees Celsius for 4 hours;

[0058] Liquid seed culture: culture medium: yeast powder 0.5%, peptone 0.5%, sodium chloride 0.5%, sucrose 1%, pH value 7, liquid volume 50 ml / 250 ml shake flask, sterilized at 115 degrees Celsius for 30 minutes, sterilized Cool after the bacteria, inoculate the slant bacteria, 37 degrees Celsius, 200 rpm for 3 hours, as a liquid seed;

[0059] Fermentation culture: medium: yeast powder 0.5%, peptone 0.5%, sodium chloride 0.5%, sucrose 1%, pH value 7, liquid volume 50 ml / 250 ml shake flask, sterilized at 115 degrees Celsius for 30 minutes, sterilized After cooling, inoculate liquid seeds with an inoculum size of 10%, ...

Embodiment 2

[0066] 1. Cultivation of Bacillus:

[0067] Slope culture: culture medium: 0.3% beef extract, 0.5% yeast extract, 0.5% peptone, 1.5% agar, pH value is 7, sterilized at 115 degrees Celsius for 30 minutes, cooled after sterilization, made into a slope, and inoculated with Bacillus Bacteria, cultivated at 28 degrees Celsius for 12 hours;

[0068] Liquid seed culture: culture medium: beef extract 0.3%, yeast extract 0.5%, peptone 0.5%, pH value 7, liquid volume 50 ml / 250 ml shake flask, sterilized at 115 degrees Celsius for 30 minutes, cooled and inoculated after sterilization Incline strains, cultivated at 28 degrees Celsius and 180 rpm for 10 hours, as liquid seeds;

[0069] Fermentation culture: medium: beef extract 0.3%, yeast extract 0.5%, peptone 0.5%, pH value 7, liquid volume 50 ml / 250 ml shake flask, sterilized at 115 degrees Celsius for 30 minutes, cooled after sterilization, and inoculated liquid Seeds, 10% inoculum, cultivated for 10 hours at 28 degrees Celsius and 180...

Embodiment 3

[0075] 1. Cultivation of Rhodococcus erythropolis:

[0076] Slope culture: culture medium: beef extract 0.3%, peptone 1.0%, sodium chloride 0.5%, agar 1.5%, pH value 7, sterilized at 115 degrees Celsius for 30 minutes, cooled after sterilization, made into a slope, inoculated with red Rhodococcus strains, cultivated at 30 degrees Celsius for 12 hours;

[0077] Liquid seed culture: medium: beef extract 0.3%, peptone 1.0%, sodium chloride 0.5%, pH value 7, liquid volume 50 ml / 250 ml shake flask, sterilized at 115 degrees Celsius for 30 minutes, cooled after sterilization, Inoculate the slant bacteria, culture at 30 degrees Celsius and 180 rpm for 10 hours, as liquid seeds;

[0078] Fermentation culture: culture medium: beef extract 0.3%, peptone 1.0%, sodium chloride 0.5%, pH value 7, liquid volume 50 ml / 250 ml shake flask, sterilized at 115 degrees Celsius for 30 minutes, cooled and inoculated after sterilization Liquid seeds, 10% inoculum size, 30 degrees Celsius, 180 rpm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com