Titanium dioxide nano-pore array thin film and preparation thereof

A nanohole array, titanium dioxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem of not being able to manufacture a large-area ordered hole array titanium dioxide film, and ordering holes cannot be made from it Array titanium dioxide thin film, unable to manufacture ordered hole array titanium dioxide thin film and other problems, to achieve the effect of easy peeling and transfer of substrate, fast and easy heat treatment, and wide adjustable range of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

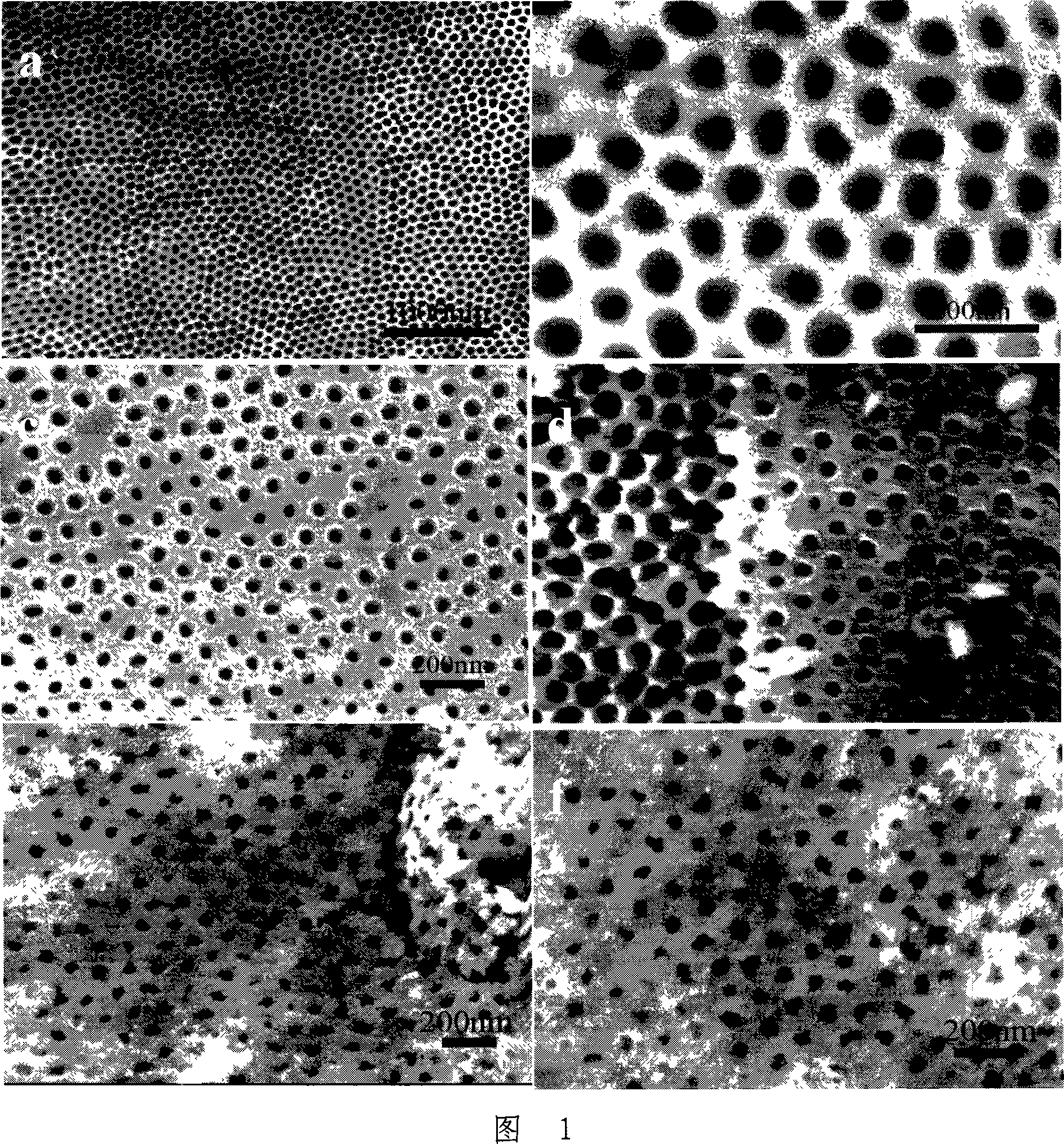

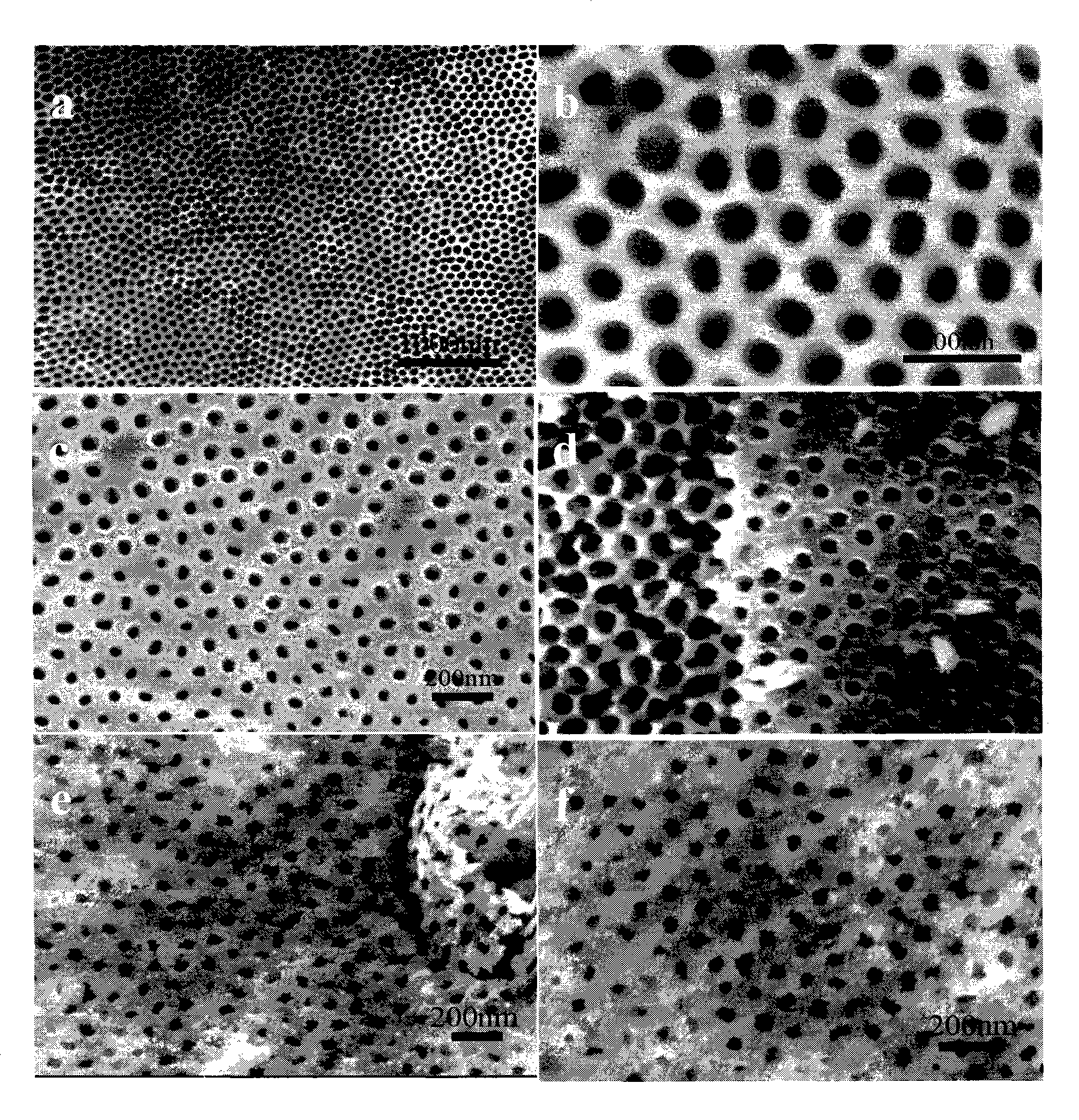

[0015] Embodiment 1: complete preparation successively according to the following steps: the first step, the aluminum flake that purity is 99.9% is 10 in vacuum degree -3Pa, after annealing at 400°C for 7 hours, first place one side of it in an acid solution with a concentration of 0.1M as an anode, anodize it at a DC voltage of 25V and a temperature of 0°C for 7 hours, and then place it at a temperature of 50 Soak in a mixed solution of 4wt% phosphoric acid and 2wt% chromic acid at ℃ for 12h; wherein, the acid solution is oxalic acid solution. Next, the anodized side was anodized for the second time under the same process conditions for 24 hours to obtain a porous alumina template with a pore diameter of 20 nm similar to that shown in Figure 1a and Figure 1b. In the second step, first mix absolute ethanol, glacial acetic acid and tetrabutyl titanate with a concentration of 0.5M according to the volume ratio of 0.8:0.5:0.3 and stir evenly to obtain a mixed solution A, then mix...

Embodiment 2

[0016] Embodiment 2: finish preparation successively according to the following steps: the first step, the aluminum flake that purity is 99.9% is 10 in vacuum degree -3 Pa, after annealing at 450°C for 6 hours, first place one side of it in an acid solution with a concentration of 0.2M as an anode, anodize it at a DC voltage of 60V and a temperature of 2°C for 6 hours, and then place it at a temperature of 55 Soak in a mixed solution of 5wt% phosphoric acid and 1.8wt% chromic acid at ℃ for 11 hours; wherein, the acid solution is oxalic acid solution. Next, the anodized side was anodized for the second time under the same process conditions for 23 hours to obtain a porous alumina template with a pore diameter of 50 nm similar to that shown in Fig. 1a and Fig. 1b. In the second step, first mix absolute ethanol, glacial acetic acid and tetrabutyl titanate with a concentration of 0.55M according to the volume ratio of 0.9:0.4:0.4 and stir evenly to obtain a mixed solution A, then ...

Embodiment 3

[0017] Embodiment 3: complete preparation successively according to the following steps: the first step, the aluminum flake that purity is 99.99% is 10 in vacuum degree -4 Pa, after annealing at a temperature of 500°C for 6 hours, first place one side of it in an acid solution with a concentration of 0.3M as an anode, anodize it at a DC voltage of 95V and a temperature of 3°C for 6 hours, and then place it at a temperature of 60 Soak in a mixed solution of 6wt% phosphoric acid and 1.5wt% chromic acid at ℃ for 10h; wherein, the acid solution is oxalic acid solution. Next, the anodized side was again anodized for a second time under the same process conditions for 21 hours to obtain a porous alumina template with a pore diameter of 80 nm as shown in Figure 1a and Figure 1b. In the second step, first mix absolute ethanol, glacial acetic acid and tetrabutyl titanate with a concentration of 0.6M according to the volume ratio of 1:0.3:0.5 and stir evenly to obtain a mixed solution A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com