Method for producing reducing pollutant in water with ultraviolet light photocatalysis degradation

A technology for the production of hydrogen and pollutants, applied in chemical instruments and methods, light water/sewage treatment, hydrogen, etc., can solve the problems of easy explosion and low yield, and achieve the effects of no need for heat dissipation, low energy consumption, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

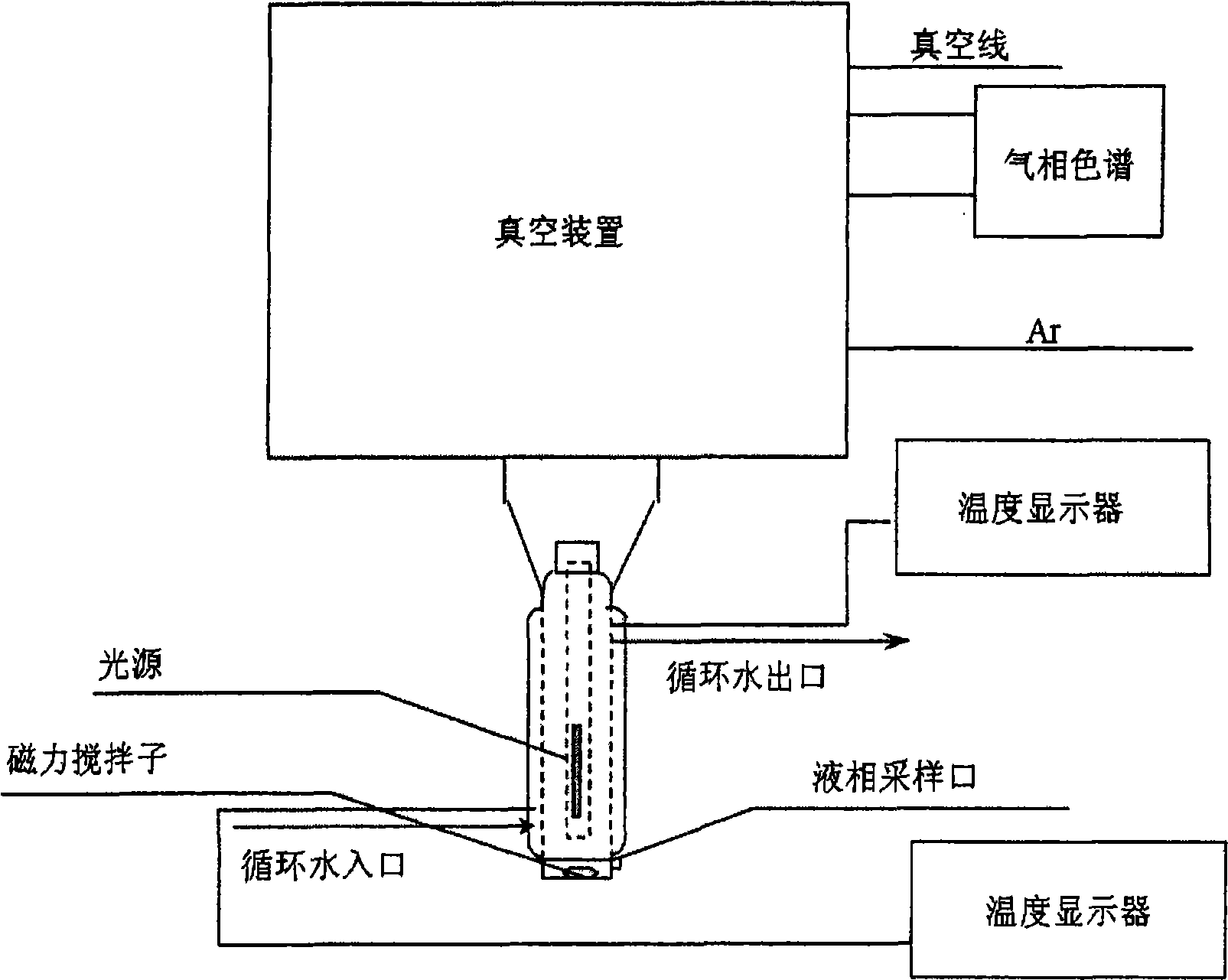

Method used

Image

Examples

Embodiment 1

[0029] Photocatalyst Pt / TiO 2 Preparation method of photodeposition: add hexahydrate chloroplatinic acid aqueous solution to DegussaP25 TiO 2 In the suspension of powder and water (the addition amount of catalyzer is not strictly limited in the present invention), under nitrogen atmosphere and magnetic stirring, 250W high-pressure mercury lamp top irradiates 10h, and reactor constant temperature is 25 ± 3 ℃, after reaction finishes, use 5 No. sand core funnel and vacuum pressure filtration, and then wash the photocatalyst with deionized water until the conductivity of the filtrate after suction filtration is less than 10 μs cm -1 . After vacuum-drying at 120°C for 10 hours, it was ground through a 300-mesh sieve.

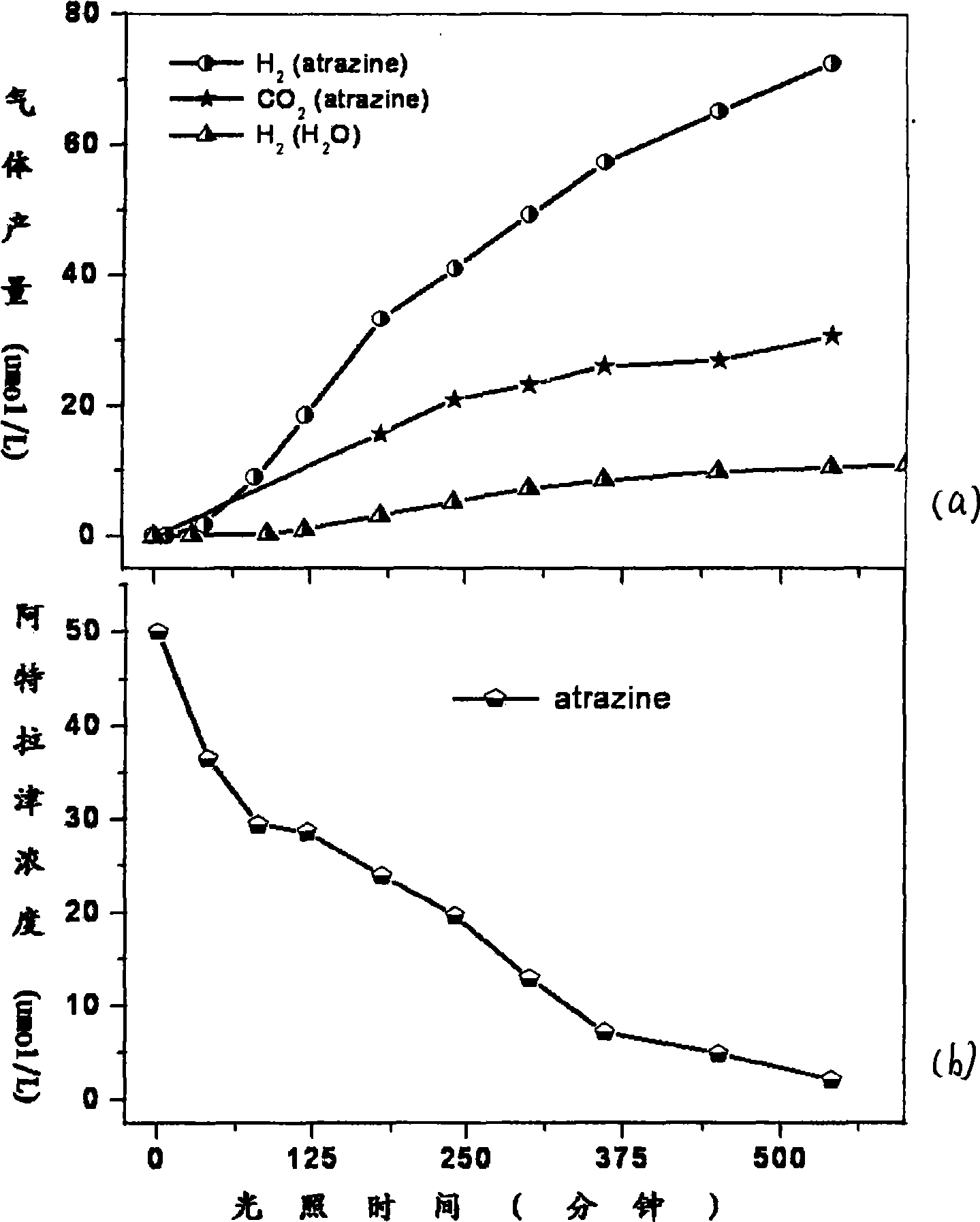

[0030] In this embodiment, the reduced water body pollutant atrazine (atrazine) is taken as an example for illustration. Atrazine is a selective herbicide used in large quantities, resulting in serious residues and polluting groundwater sources. Atrazine is also...

Embodiment 2

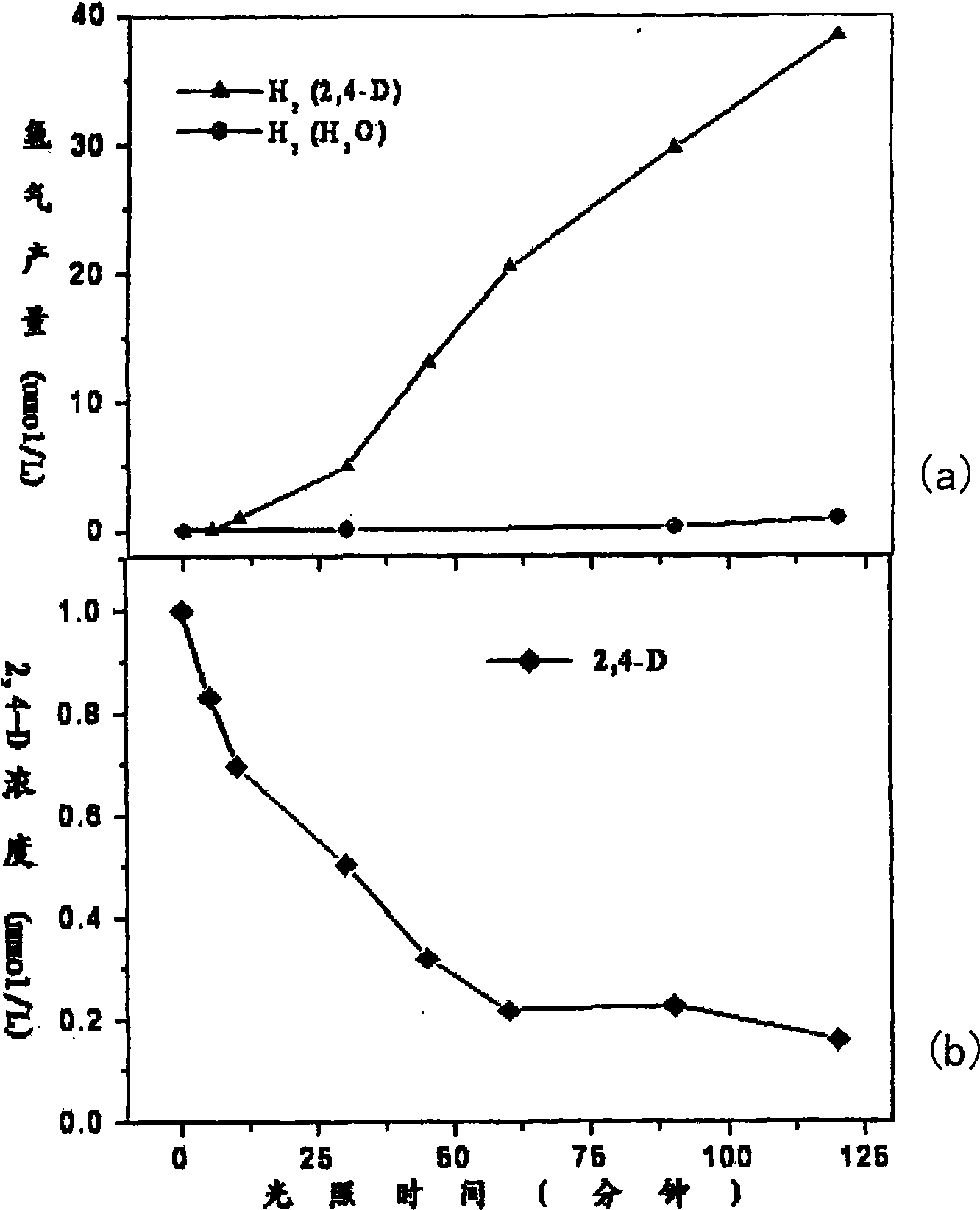

[0033] The difference from Example 1 is that the reducing pollutant uses 2,4-dichlorophenoxyacetic acid (2,4-D) (concentration is 1.0 mmol / l). 2,4-D is the world's first herbicide, the second most selective herbicide in the world, and the world's first broadleaf weed herbicide. It, like atrazine, pollutes water bodies through agricultural and horticultural use. Although 2,4-D has low acute toxicity, it is a potential endocrine disruptor, and its main biodegradation product is 2,4-dichlorophenol, and skin contact with molten 2,4-dichlorophenol can Rapid lethality. Elimination of 2,4-D therefore also has important environmental implications.

[0034] With the operation of embodiment 1, the result is as image 3 a, b shown. 2,4-D was 84% degraded by liquid chromatography analysis after 2 hours of light irradiation. At this time, 38.4 μmol of hydrogen gas was produced. The photolysis of water under the same conditions produces 0.925 μmol of hydrogen. Therefore, 2,4-D, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com