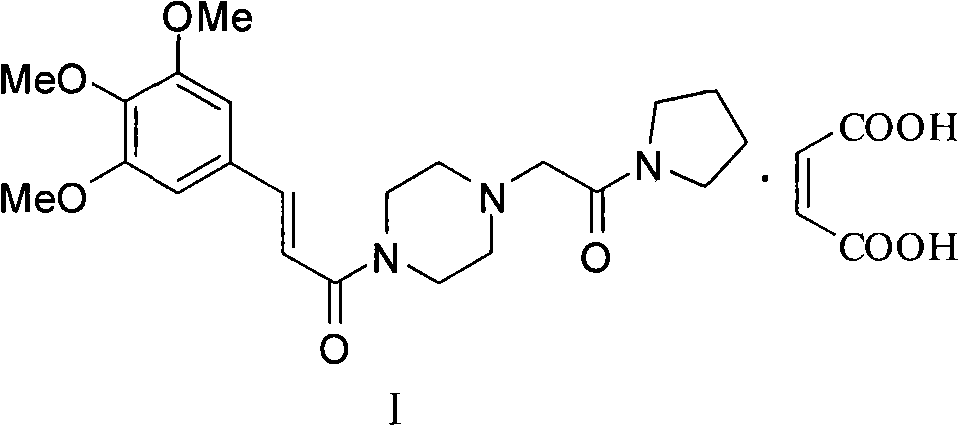

Improved preparation method for cinepazide maleate

A technology of cinepazide maleate and piperazine is applied in a preparation field of cinepazide maleate to achieve the effects of high product yield, low energy consumption and equipment requirements, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

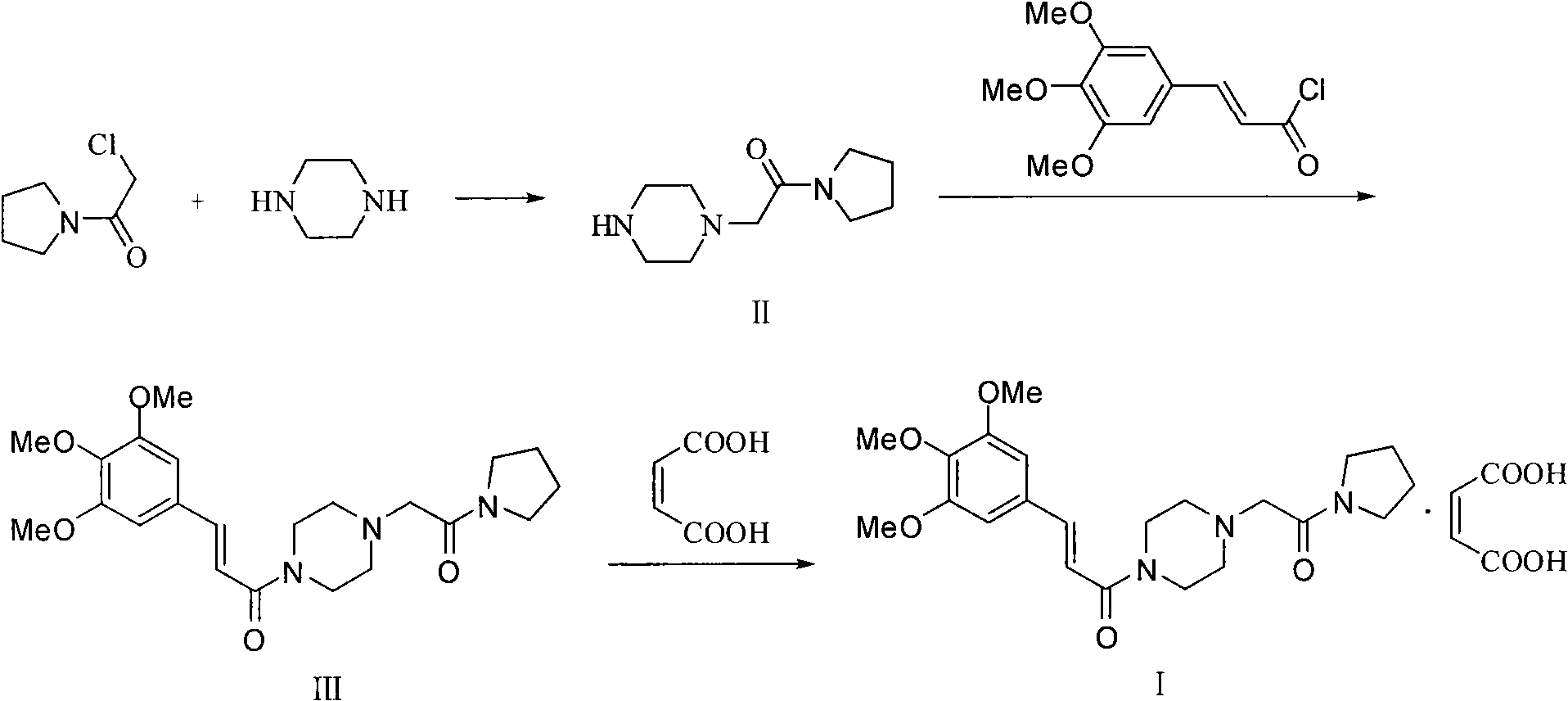

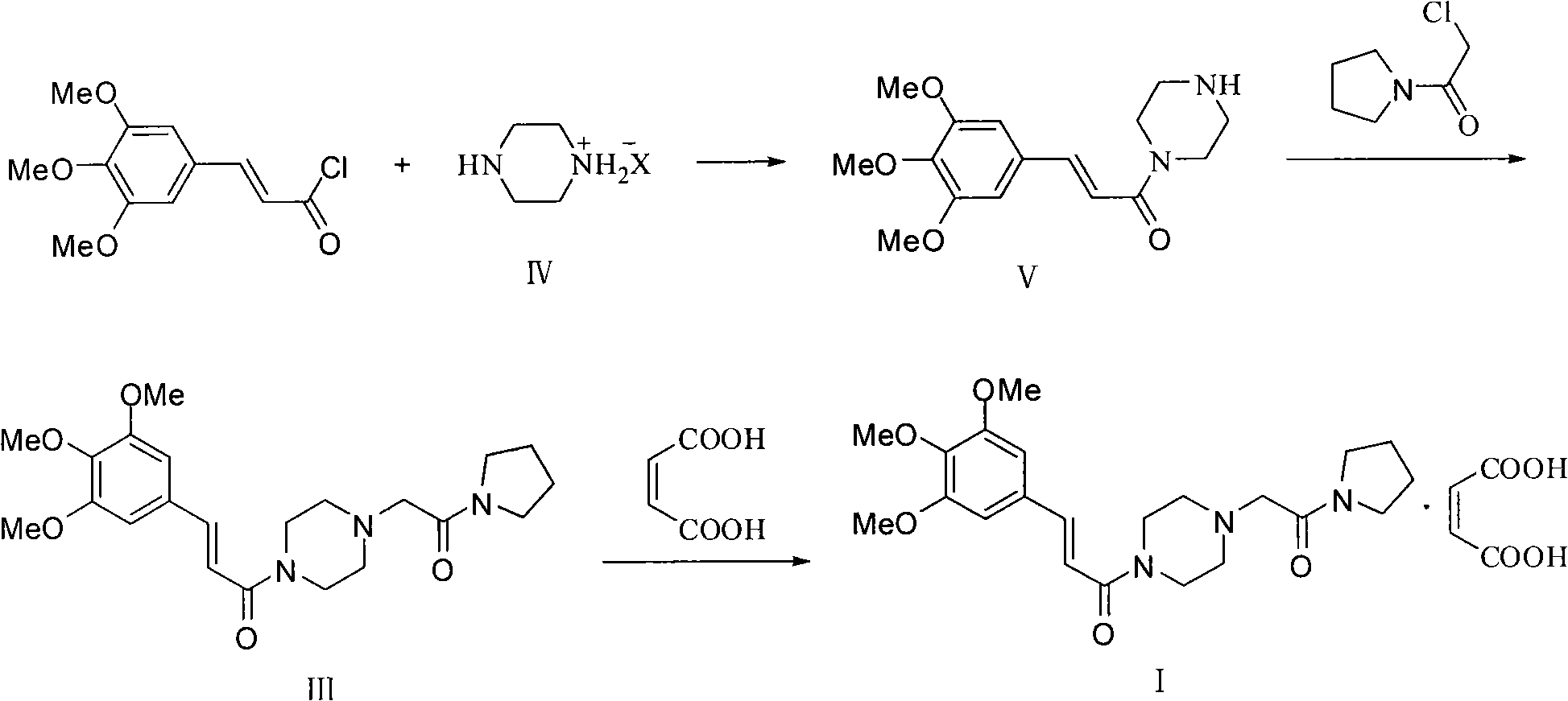

[0056] 1) Preparation of 1-[(1-tetrahydropyrrolecarbonyl)methyl]piperazine

[0057] Reaction formula:

[0058]

[0059] At room temperature, add 11.7g (0.136mol) of anhydrous piperazine and 6.3g (0.045mol) of anhydrous potassium carbonate into 100ml of absolute ethanol and stir evenly. Then slowly add a solution of 6.6g (0.045mol) chloroacetylpyrrolidine and 30ml of absolute ethanol dropwise; keep warm for 3 to 4 hours (GC or TLC to follow the reaction process: methanol is the developer, iodine, chloroacetylpyrrolidine R f = 0.7, 1-piperazine acetylpyrrolidine R f =0.4), remove the solid residue by suction filtration, use 20ml acetone to stir at room temperature after 10min ice-water bath cooling after the obtained filtrate spins to dryness, remove the white powder (being piperazine, recycling) by suction filtration, after the filtrate spins to dryness Vacuum drying gave 8.4 g of a yellowish white solid with a yield of 95.6% and a GC purity of ≥99%.

[0060] 1 H-NMR (DM...

Embodiment 2

[0077] 1) Preparation of 1-[(1-tetrahydropyrrolecarbonyl)methyl]piperazine

[0078] Reaction formula:

[0079]

[0080] At room temperature, add 15.6g (0.181mol) of anhydrous piperazine into 100ml of absolute ethanol and stir evenly. Then slowly add a solution of 6.6g (0.045mol) chloroacetylpyrrolidine and 30ml of absolute ethanol dropwise; keep warm for 3 to 4 hours (GC or TLC to follow the reaction process: methanol is the developer, iodine, chloroacetylpyrrolidine R f = 0.7, 1-piperazine acetylpyrrolidine R f=0.4); after the reaction solution was evaporating to dryness, stir it with 20ml acetone at room temperature for 10min and then cool it in an ice-water bath, remove the white powder (being piperazine, recycle) by suction filtration, and vacuum-dry the filtrate to obtain a yellowish white color after evaporating to dryness. The solid is 8.8g, the yield is 100%, and the GC purity is 90.3%.

[0081] 1 H-NMR (DMSO-d 6 ): δ1.747 (m, 2H, pyrrolidine-CH 2 -), δ1.829 (...

Embodiment 3

[0098] 1) Preparation of 1-[(1-tetrahydropyrrolecarbonyl)methyl]piperazine

[0099] Reaction formula:

[0100]

[0101] At room temperature, 11.7g (0.136mol) of anhydrous piperazine and 6.3g (0.045mol) of anhydrous potassium carbonate were added to 100ml of absolute ethanol and stirred evenly. Then slowly add a solution of 6.6g (0.045mol) chloroacetylpyrrolidine and 30ml of absolute ethanol dropwise; keep warm for 3 to 4 hours (GC or TLC to follow the reaction process: methanol is the developer, iodine, chloroacetylpyrrolidine R f = 0.7, 1-piperazine acetylpyrrolidine R f =0.4), remove the solid residue by suction filtration, use 20ml acetone to stir at room temperature after 10min ice-water bath cooling after the obtained filtrate spins to dryness, remove the white powder (being piperazine, recycling) by suction filtration, after the filtrate spins to dryness Vacuum drying gave 8.4 g of a yellowish white solid with a yield of 95.6% and a GC purity of ≤99%.

[0102] 1 H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com