Solid phase method for synchronizing Argatroban

A technology of argatroban and solid-phase method, applied in the field of solid-phase synthesis of argatroban, which can solve the problem of low yield in liquid phase reaction, increased post-reaction treatment work, and difficult purification and separation of intermediates and target products And other problems, to achieve considerable economic and practical value, low cost, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

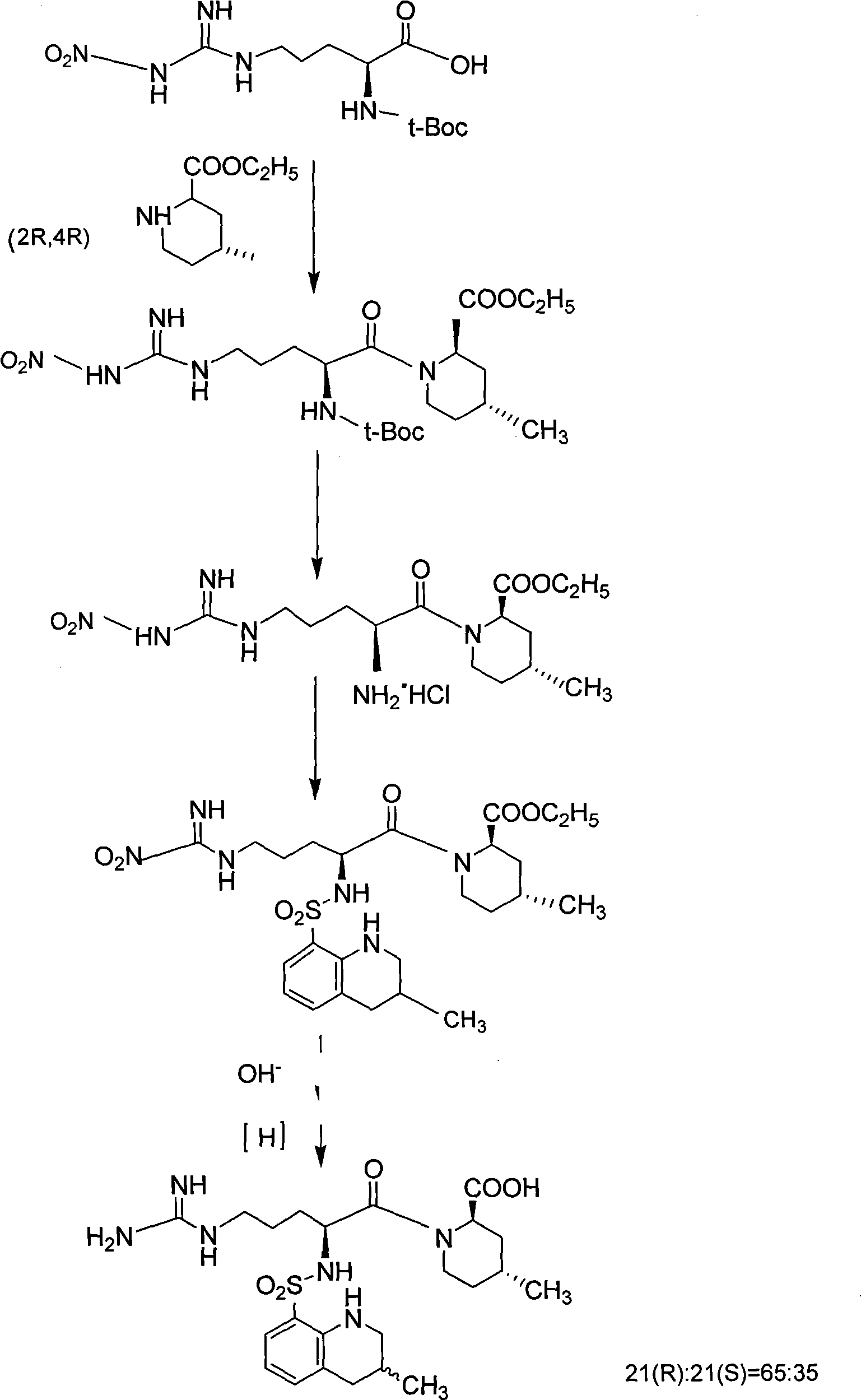

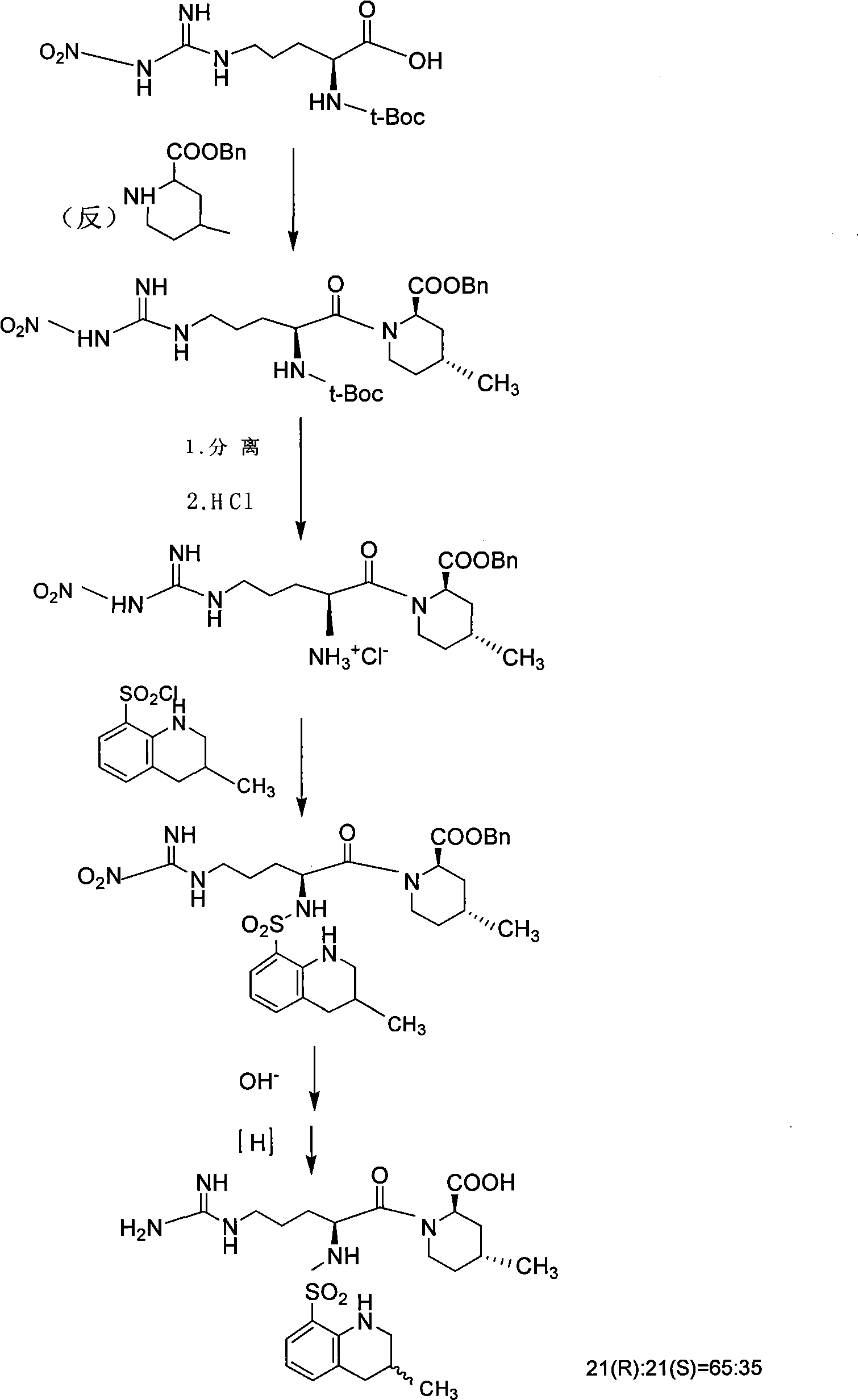

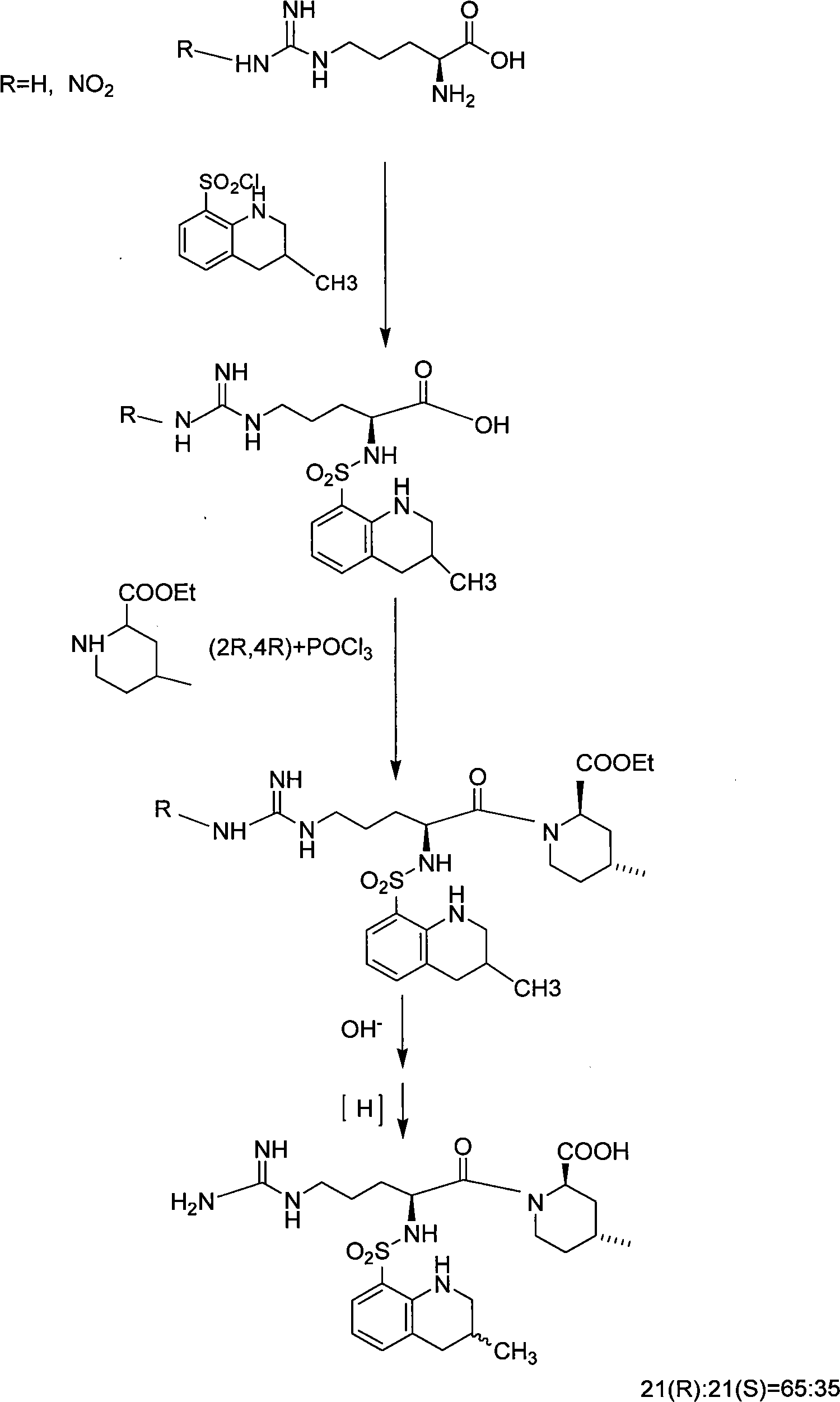

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Preparation of (2R, 4R)-N-Fmoc-4-methyl-2-piperidinecarboxylic acid-chloro resin or hydroxyl resin

[0042] Add 200.0 g of chlorine resin or hydroxyl resin (substitution degree: 0.5 mmol / g) into a 1000 ml round bottom flask, add DMF 600 ml, and stir vigorously. In an ice-water bath, 36g (2R, 4R)-N-Fmoc-4-methyl-2-piperidinecarboxylic acid and equal molar ratios of DIC, HOBt, and DIPEA were added to the above round-bottomed flask filled with resin to react for 2 hours. After the reaction is completed, filter, wash 3 times with DMF and 3 times with DCM, then shrink with methanol for 30 minutes to obtain (2R, 4R)-N-Fmoc-4-methyl-2-piperidinecarboxylic acid-chloro resin or hydroxyl resin, and detect The degree of substitution is 0.48mmol / g, and the yield is 96%.

Embodiment 2

[0043] Embodiment 2: Preparation of (2R, 4R)-4-methyl-2-piperidinecarboxylic acid-chloro resin or hydroxyl resin

[0044]Add (2R,4R)-N-Fmoc-4-methyl-2-piperidinecarboxylic acid and chlorine resin prepared above into a 1000ml round bottom flask, add 600ml of 20% DBLK and stir vigorously for 30min. After the reaction was completed, filter, wash with DMF for 3 times, and DCM for 3 times, and set aside for use.

Embodiment 3

[0045] Embodiment 3: Preparation of Fmoc-Arg (X)-(2R, 4R)-4-methyl-2-piperidinecarboxylic acid-chloro resin or hydroxyl resin

[0046] Put the (2R,4R)-4-methyl-2-piperidinecarboxylic acid-chloro resin or hydroxyl resin to be used into a 1000ml round bottom flask, add 700ml tetrahydrofuran and stir vigorously. In an ice-water bath, 65g of Fmoc-Arg(X)-OH and equal molar ratios of DIC, HOBt, and DIPEA were added to the above round-bottomed flask filled with resin and reacted for 2 hours. After the reaction is completed, filter, wash 3 times with DMF, wash 3 times with DCM, and shrink with methanol for 30 minutes to obtain Fmoc-Arg(X)-(2R,4R)-4-methyl-2-piperidinecarboxylic acid-chloro resin or hydroxyl Resin, the detected substitution degree is 0.45mmol / g, and the yield is 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com