Preparation method of polypropylene fiber for absorbing mercury ions in waste water

A polypropylene fiber and mercury ion technology, applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of lack of organic mercury ion adsorption materials, non-recyclable utilization, low economic benefits, etc. Achieve the effect of low cost, convenient source and good mercury adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

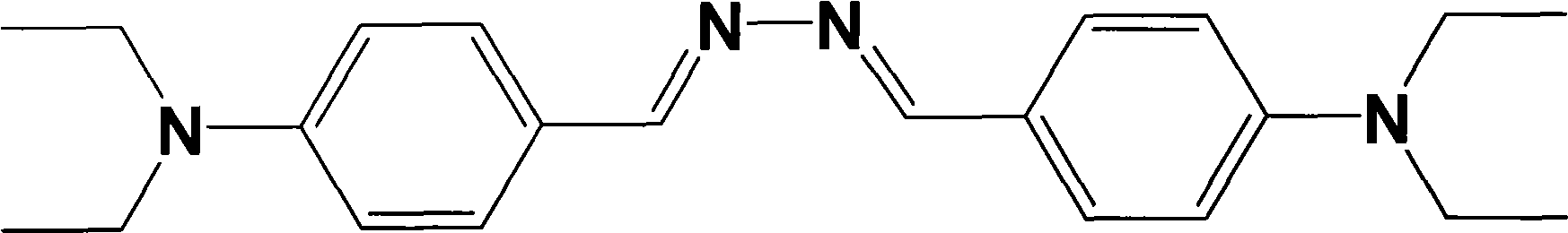

[0062] (1) Synthesis of organic mercury ion adsorption compound 1 (n 1 =0,n 2 =1)

[0063] Weigh 1.5 grams (8.4 millimoles) of 4-diethylaminobenzaldehyde and dissolve it in 50 milliliters of absolute ethanol, heat it in a water bath to 80 degrees Celsius, slowly add 0.17 grams (4.2 millimoles) of 85t% hydrazine hydrate dropwise, and condense Reflux for 1.5h, a yellow precipitate was obtained. After recrystallization, it was filtered and dried to obtain the target compound 1 as a yellow solid with a mass of 1.01 g (yield 57.4%).

[0064] Mass spectrum (EI): m / z350

[0065] Melting point: 193 degrees Celsius

[0066] H NMR 1 H-NMR (300MHz, CDCl 3 , 25 degrees Celsius, TMS): δ=8.54 (s, 2H), 7.67 (d, 4H), 6.67 (d, 4H), 3.42 (m, 8H), 1.19 (m, 12H). Elemental Analysis C 22 h 30 N 4 (35.025) Calculated: C, 75.43; H, 8.57; N, 16.00. Measured values: C, 75.73; H, 8.77; N, 15.54.

[0067] (2) Synthesis of organic mercury ion adsorption compound 2 (n 1 = 1, n 2 =1, R=-Ph) ...

Embodiment 2

[0073] Preparation of Luminescent Polypropylene Fiber

[0074] Raw materials: 200 grams of polypropylene, 2 grams of organic mercury ion adsorption compound

[0075] Preparation method: After mixing the above raw materials evenly, melt blending with a multifilament 400 melt spinning machine, extrusion and spinning. The spinning speed is 400 meters per minute, the spinning temperature is 270 degrees Celsius, and the post-drawing ratio is 2.8 times.

[0076] Results: The specifications of the luminescent fiber drawing yarn are 67 dtex per 18 holes, the strength is 3.89 centinewtons per dtex, enough fibers can make the content of mercury ions in water less than 10 -6 moles per liter.

Embodiment 3

[0078] Preparation of Luminescent Polypropylene Fiber

[0079] Raw materials: 200 grams of polypropylene, 4 grams of organic mercury ion adsorption compound

[0080] Preparation method: After mixing the above raw materials evenly, melt blending with a multifilament 400 melt spinning machine, extrusion and spinning. The spinning speed is 600 meters per minute, the spinning temperature is 290 degrees Celsius, and the post-drawing ratio is 2.8 times.

[0081] Results: The specification of the luminescent fiber drawing yarn is 62 dtex per 18 holes, the strength is 3.51 centinewtons per dtex, enough fibers can make the content of mercury ions in water less than 10 -6 moles per liter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com