A recovery method of tin in tin-stripping waste liquid

A recovery method and technology for waste liquid, applied in the direction of improving process efficiency, can solve problems such as long reaction time, harsh reaction conditions, high temperature and high pressure, etc., and achieve good environmental and social benefits, low production equipment requirements, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

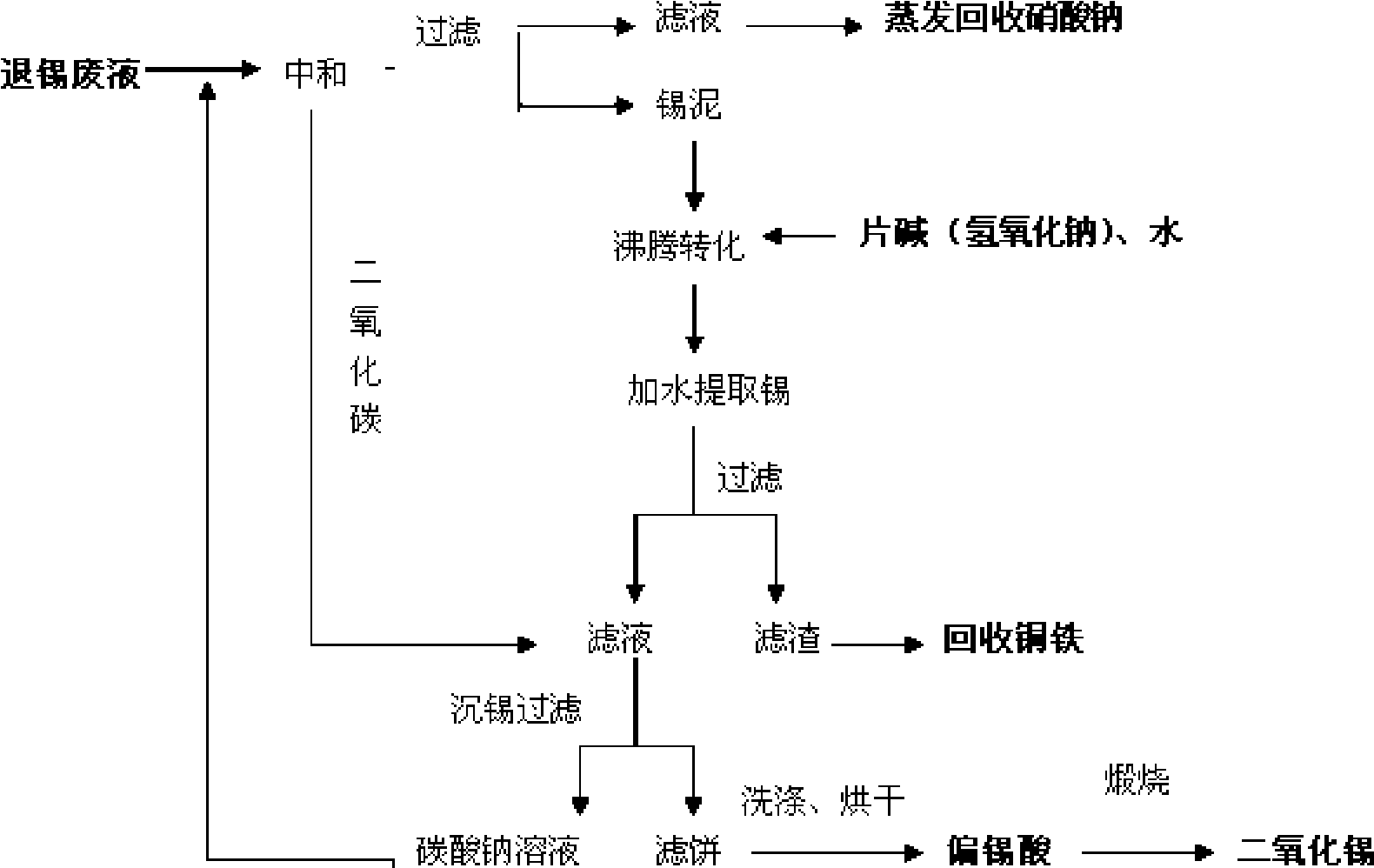

Method used

Image

Examples

Embodiment 1

[0042] Take 1L of tin stripping waste liquid from manufacturer 1, neutralize it with saturated sodium carbonate solution to pH 3.5, filter, transfer the filter cake to a 2L polytetrafluoroethylene beaker, add water and 166.8 grams of sodium hydroxide, tin and sodium hydroxide The molar ratio is 1:4, the amount of water added is such that the weight ratio of water to the dried filter cake is 2 to 4, boiled for 1 hour, transferred to a 5L beaker, and 2L of water is added (the amount of water added is such that sodium stannate can be fully dissolved), mechanically stirred for 60 minutes, filtered, the filtrate was poured into a plastic reactor, and carbon dioxide was introduced to stir the reaction so that the tin precipitation was complete, filtered, washed, and the filter cake was dried to obtain 170.3g metastannic acid powder, tin The recovery rate was 96%. To judge that the tin precipitation is complete, you can take the filtrate after filtration and continue to pass carbon d...

Embodiment 2

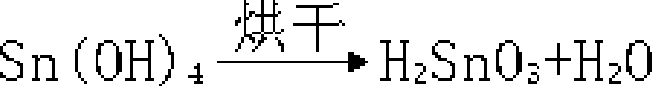

[0046]Take 1L of tin stripping waste liquid from manufacturer 1, neutralize the sodium carbonate solution obtained by filtering after carbon dioxide tin precipitation in Example 1 until the pH is 6-6.5, filter, transfer the filter cake into a 2L polytetrafluoroethylene beaker, add water and 290 gram of sodium hydroxide, the molar ratio of tin to sodium hydroxide is 1:7, the amount of water added is such that the weight ratio of water to the dried filter cake is 2 to 4, boil for 2 hours, transfer to a 5L beaker, add water 2L, mechanically stirred for 30 minutes, filtered, poured the filtrate into a plastic reactor, introduced carbon dioxide and stirred until tin precipitation was complete, filtered, washed, and dried to obtain metastannic acid powder. Calcined at 950° C. for 1 hour to obtain 153 g of white tin dioxide powder, the recovery rate of tin was 97.0%.

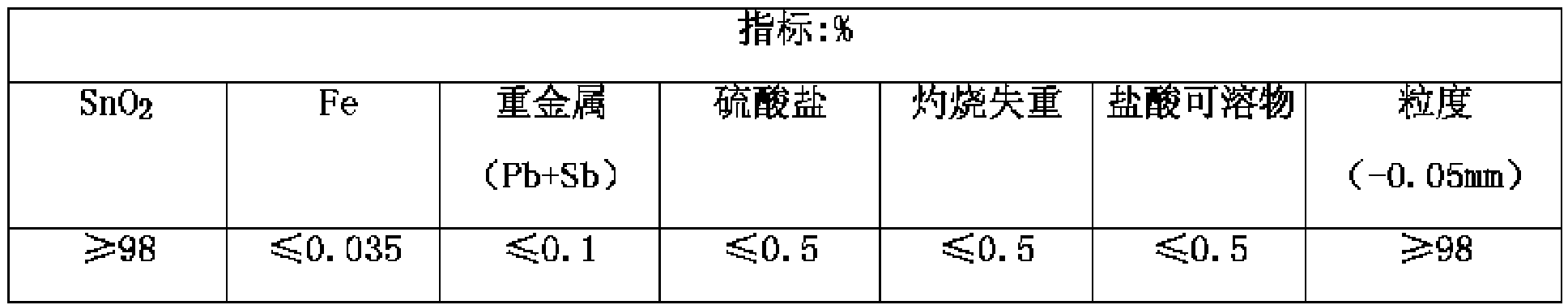

[0047] The chemical analysis result of the tin dioxide product that embodiment two makes is as follows table (%):

...

Embodiment 3

[0050] Take 1L of tin stripping waste liquid from manufacturer 3, use Example 2 to neutralize the obtained filtrate after carbon dioxide tin precipitation to pH 9, filter, transfer the filter cake to a 2L polytetrafluoroethylene beaker, add water and 157.3 grams of sodium hydroxide , the molar ratio of tin to sodium hydroxide is 1:9, the amount of water added is to make the weight ratio of water to dry filter cake 2 to 4, boil for 2 hours, transfer to a 5L beaker, add 900ml of water, and mechanically stir for 30 Minutes, filter, pour the filtrate into a plastic reactor, pass through carbon dioxide to stir the reaction until the tin precipitation is complete, filter, wash, dry the filter cake and calcinate at 600°C for 3 hours to obtain 64.2g of white tin dioxide Powder, the recovery rate of tin is 96.2%.

[0051] The chemical analysis result of the tin dioxide product that embodiment three makes is as follows table (%):

[0052] Tin oxide Loss on ignition Hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com