Method for preparing lithium iron phosphate/nanometer carbon composite anode material

A composite positive electrode material, lithium iron phosphate technology, applied in the direction of electrode manufacturing, battery electrodes, electrical components, etc., can solve the problems of carbon nanotube agglomeration increasing the amount of raw materials, difficulty in fully dispersing carbon nanotubes, and reducing the capacity of composite materials, etc. , to improve the reversible discharge capacity, prevent agglomeration, and improve the ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

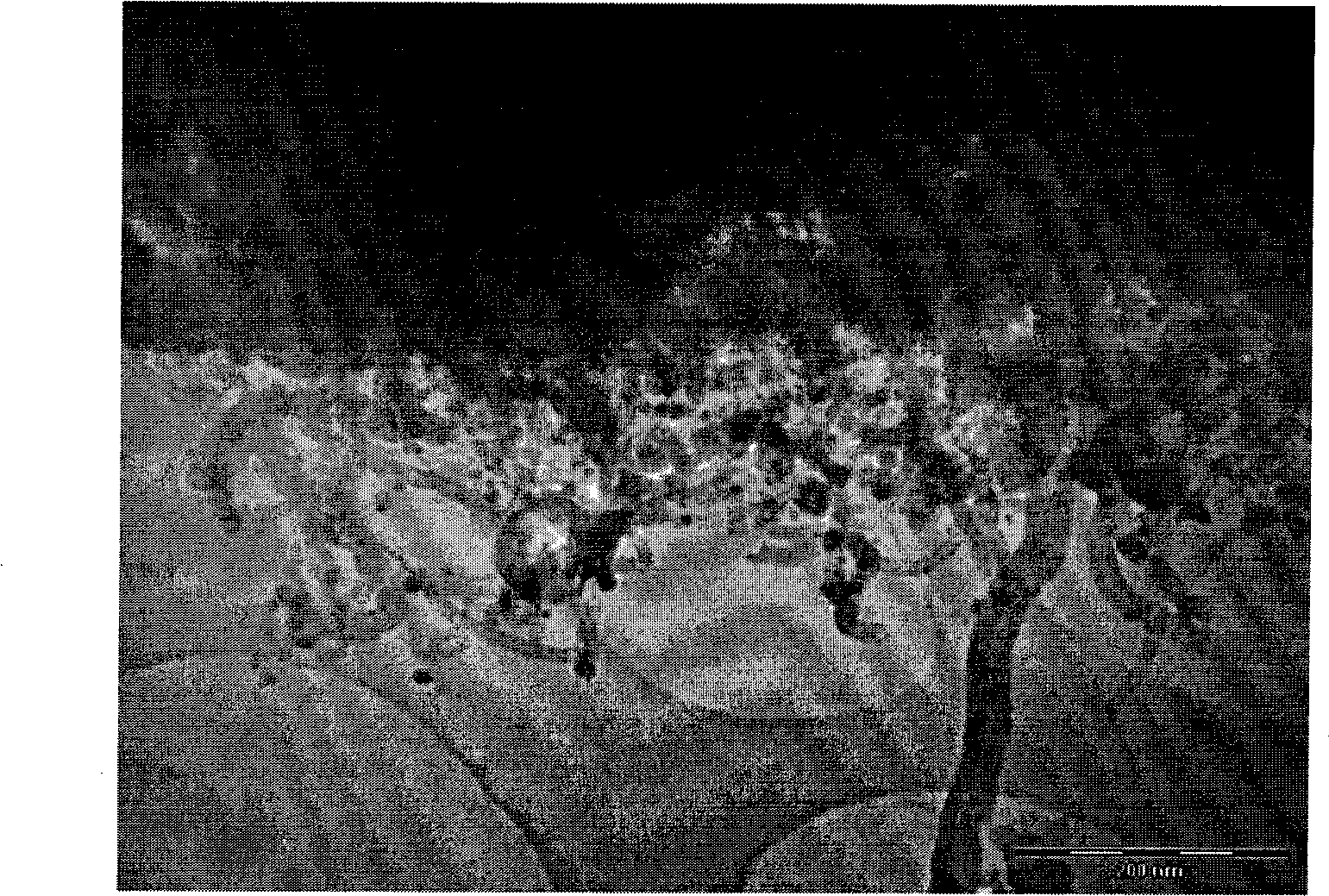

[0039]Weigh 3 grams of nickel powder, 37 grams of lithium carbonate, 173 grams of ferrous oxalate, and 116 grams of ammonium dihydrogen phosphate, and use absolute ethanol as a dispersant to ball mill in a ball mill for 6 hours; the mixed precursor is vacuum dried at 50°C 12 Hours; the precursor is put into the tube furnace, vacuumed, and then high-purity nitrogen (N 2 Purity ≥99.999%), the nitrogen flow rate is 100sccm, and the temperature is increased to 750°C at a rate of 20°C / min; when the temperature rises to 750°C, the LPG is introduced and the nitrogen is turned off at the same time. The LPG flow is 100sccm. The carbon nanotubes were grown at the above temperature at a constant temperature for 60 minutes; the nitrogen flow was restored while the carbon source gas was turned off, and the nickel-doped lithium iron phosphate was prepared at a constant temperature of 750°C for 24 hours. Then, it is naturally cooled to room temperature under the protection of nitrogen atmosphere...

Embodiment 2

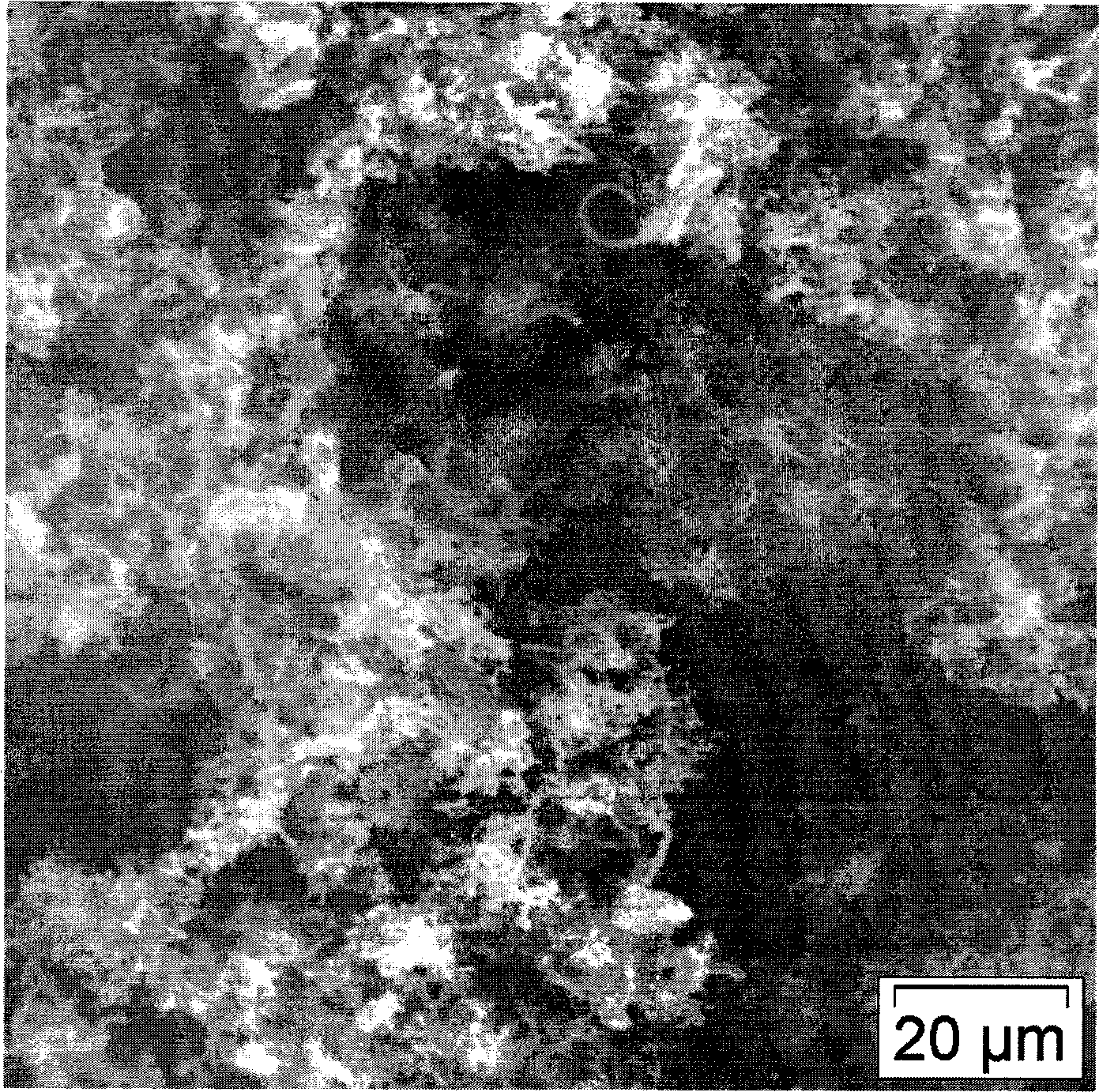

[0042] The liquefied petroleum gas in Example 1 was replaced with ethylene, and the main components of the prepared composite material were nickel-doped lithium iron phosphate and carbon nanotubes, the mass percentage of nickel-doped lithium iron phosphate was 92%, and the mass percentage of carbon nanotubes was 8%. The mixing, heating, constant temperature, electrode production, battery assembly and test conditions are the same as those in Example 1. The discharge capacity is 145mAh·g at 1C rate -1 , Reaching 95% of 0.2C discharge rate. See figure 2 As can be seen from the electron microscope photos, a large number of carbon nanotubes grow around the lithium iron phosphate, and there is no agglomeration of carbon nanotubes. It shows that the lithium iron phosphate / carbon nanotube composite cathode material can be successfully prepared under this condition, and the prepared carbon nanotubes are uniformly dispersed around the lithium iron phosphate particles, forming a lithium iro...

Embodiment 3

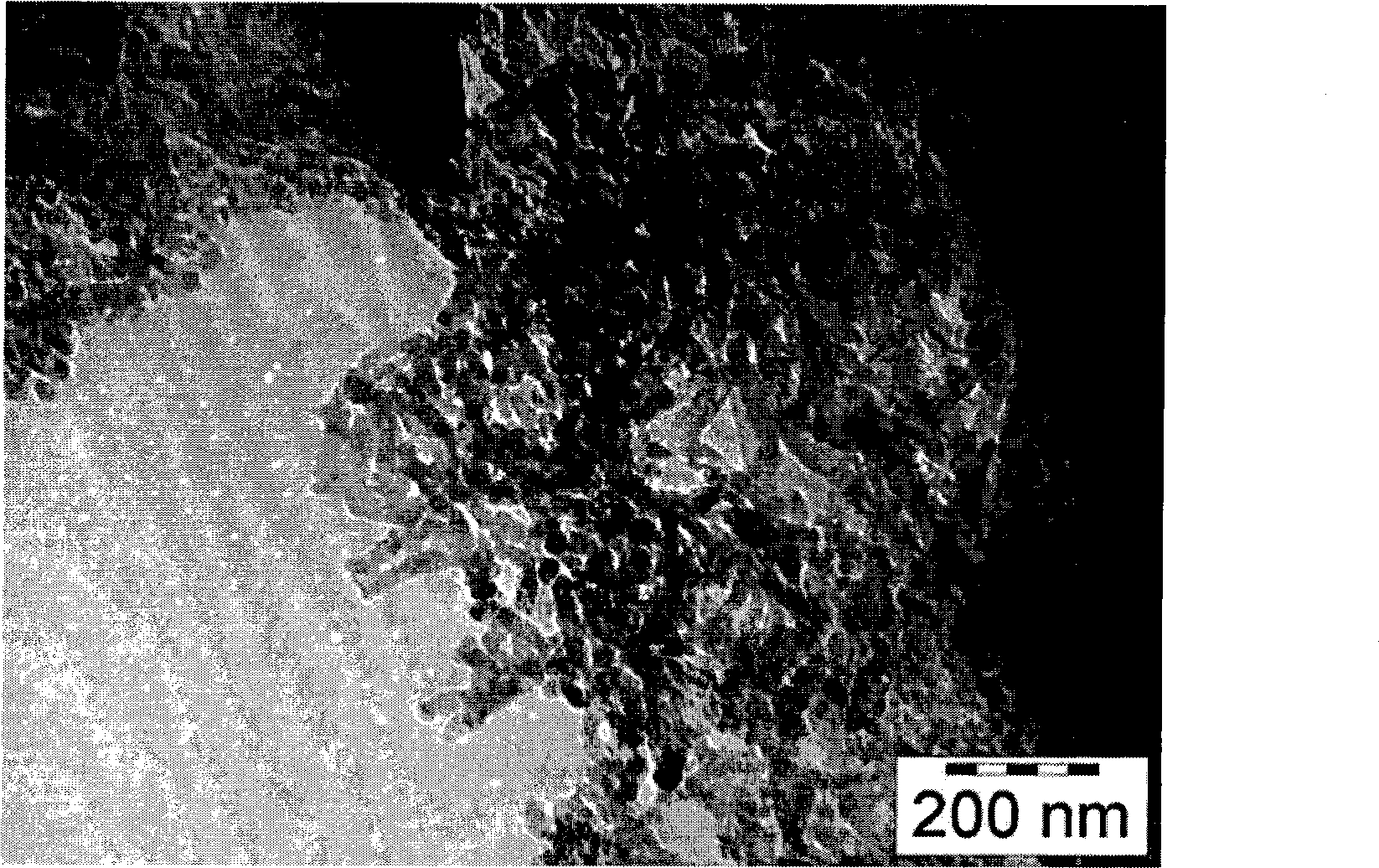

[0044] The liquefied petroleum gas in Example 1 was replaced with methane, and the protective atmosphere nitrogen was replaced with argon. The main components of the prepared composite material are nickel-doped lithium iron phosphate and carbon nanotubes, the mass percentage of nickel-doped lithium iron phosphate is 97%, and the mass percentage of carbon nanotubes is 3%. The mixing, heating, constant temperature, electrode production, battery assembly and test conditions are the same as those in Example 1. The discharge capacity is 130mAh·g at 1C rate -1 , Reaching 92% of 0.2C discharge rate. See image 3 As can be seen from the electron microscope photos, a large number of carbon fibers grow around the lithium iron phosphate, and there is no agglomeration of carbon fibers. It shows that the lithium iron phosphate / carbon fiber composite cathode material can be successfully prepared under this condition, and the prepared carbon fibers are evenly dispersed around the lithium iron ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com