Method for extracting genistein from plant nepeta japonica maxim

A technology of genistein and sophora japonicus, applied in separation methods, chemical instruments and methods, solid solvent extraction, etc., can solve the problems of low column efficiency, irregular product shape, low chromatographic efficiency, etc., and achieve the usage of solvent The effect of reduction, small amount of solvent used, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific method of this embodiment is performed according to the following steps:

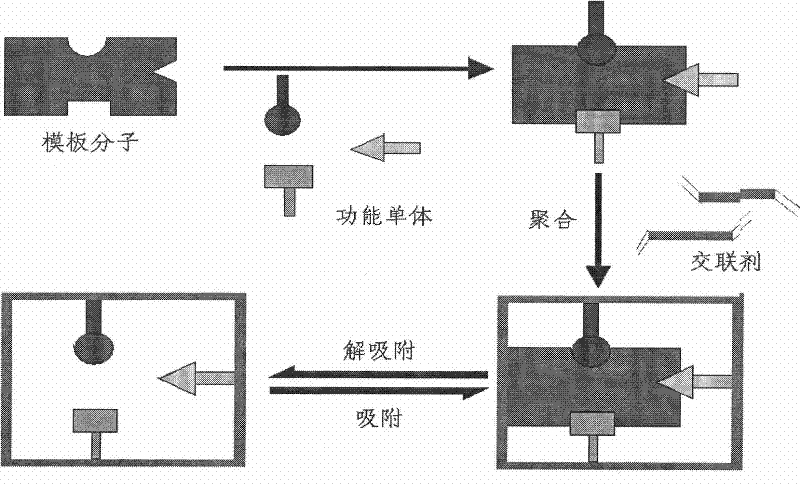

[0038] (1) Preparation of genistein molecularly imprinted polymer:

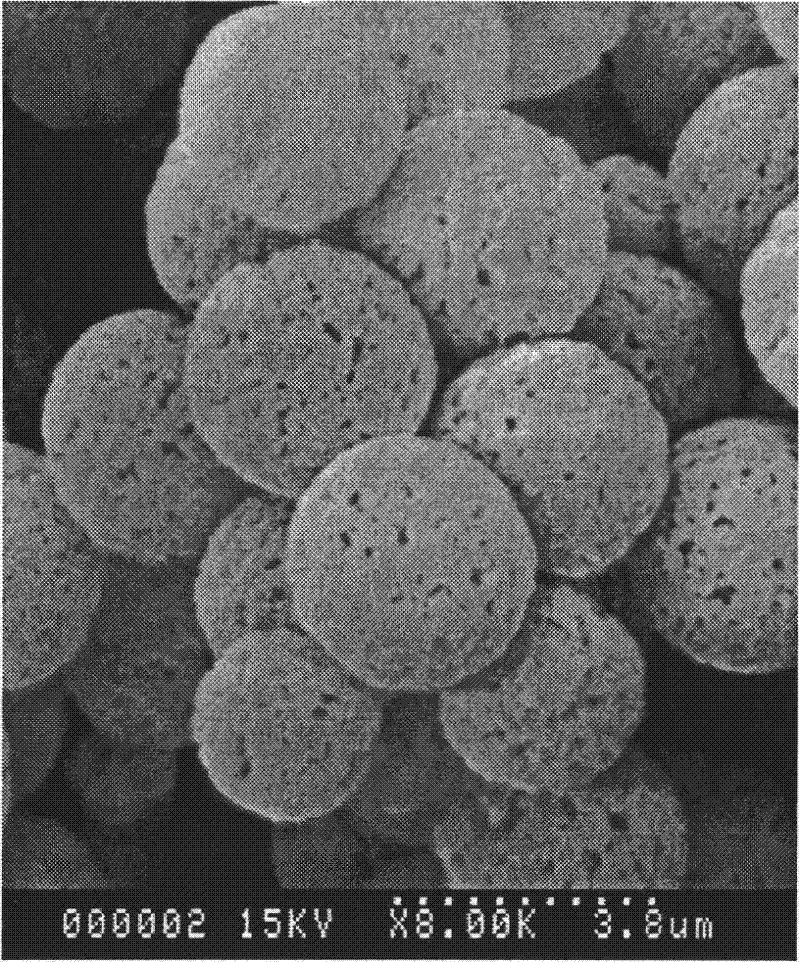

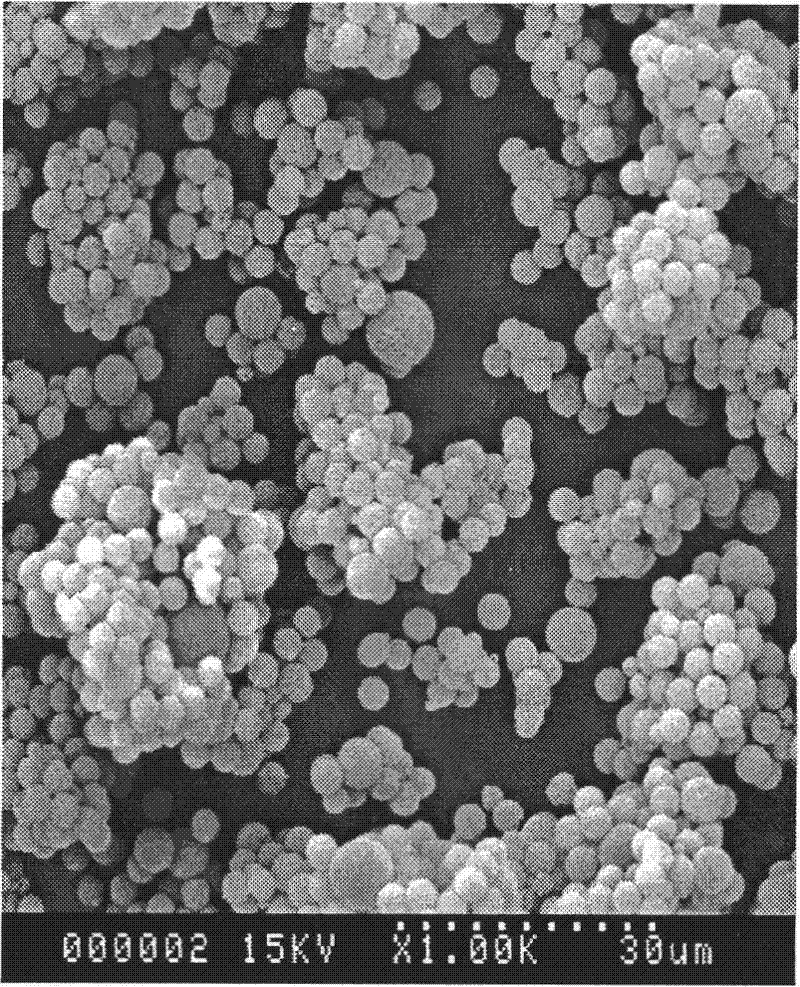

[0039] 1) Multi-step swelling polymerization:

[0040] a. First, add 0.012g of polystyrene microspheres with a particle size of 1 μm to each milliliter of microemulsion A, and react for 15 hours in a thermostatic magnetic stirrer at a rotational speed of 150 rpm at room temperature to obtain the first step swelling liquid;

[0041] Each milliliter of microemulsion A contains 0.002g of sodium dodecyl sulfonate, 0.048g of dibutyl phthalate, and the rest is tri-distilled water;

[0042] b. Then add 2.4mL of microemulsion B to each milliliter of the first step swelling liquid, and at room temperature, react for 2h in a constant temperature magnetic stirrer at a speed of 150 rpm to obtain the second step swelling liquid;

[0043] Among them, each milliliter of microemulsion B contains 0.017g of azobisisobutyronitrile, 0.099g of chl...

Embodiment 2

[0053] The specific method of this embodiment is performed according to the following steps:

[0054] (1) Preparation of genistein molecularly imprinted polymer:

[0055] 1) Multi-step swelling polymerization:

[0056] a. First, add 0.006 g of polymethacrylic acid microspheres with a particle size of 1 μm to each milliliter of microemulsion A, and react for 16 hours in a thermostatic magnetic stirrer at a rotational speed of 130 rpm at room temperature to obtain the first step swelling liquid;

[0057] Each milliliter of microemulsion A contains 0.003g of sodium dodecyl sulfonate, 0.05g of dibutyl phthalate, and the rest is tri-distilled water;

[0058] b. Then add 1.8 mL of microemulsion B to each milliliter of the first step swelling solution, and react for 2.5 hours in a thermostatic magnetic stirrer at 130 rpm at room temperature to obtain the second step swelling solution;

[0059] Each milliliter of microemulsion B contains 0.02g of azobisisobutyronitrile, 0.100g of chloroform and ...

Embodiment 3

[0068] The specific method of this embodiment is performed according to the following steps:

[0069] (1) Preparation of genistein molecularly imprinted polymer:

[0070] 1) Multi-step swelling polymerization:

[0071] a. First, add 0.010g of fluorine-containing acrylate copolymer microspheres with a particle size of 1μm to each milliliter of microemulsion A, and react for 14h in a thermostatic magnetic stirrer at a rotating speed of 100rpm at room temperature to obtain the first step swelling liquid ;

[0072] Each milliliter of microemulsion A contains 0.002g of sodium dodecyl sulfonate, 0.04g of dibutyl phthalate, and the rest is tri-distilled water;

[0073] b. Then add 2.0 mL of microemulsion B to each milliliter of the first step swelling liquid, and at room temperature, react for 1.5 hours at a rotating speed of 120 rpm in a thermostatic magnetic stirrer to obtain the second step swelling liquid;

[0074] Each milliliter of microemulsion B contains 0.015g of azobisisobutyronitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com