Digestive circulating fluid bed flue gas desulfurization method and device

A circulating fluidized bed and desulfurization device technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of construction costs, high operating costs, large amount of by-products, and large floor space. Achieve the effects of desulfurization, high desulfurization efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

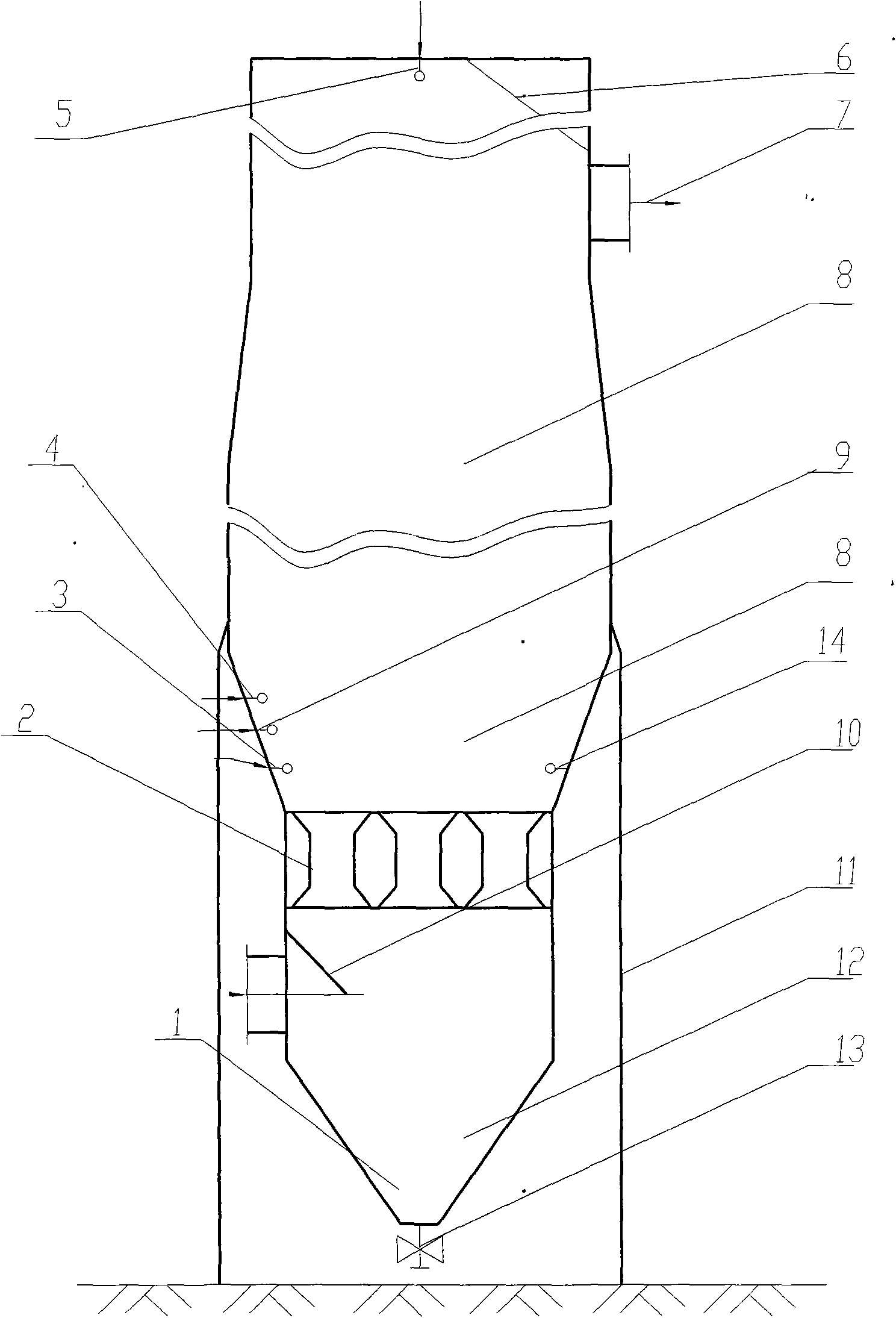

[0030] Such as figure 1 and figure 2 As shown, the digestion circulation fluidized bed flue gas desulfurization tower of the present invention includes three sections: a pre-dust removal section (lower section), a Venturi tube bundle section (middle section), and a digestion reaction section (upper section).

[0031] The lower part of the desulfurization tower is the pre-dust removal section 12, the side wall is provided with a flue gas inlet 1, the bottom is provided with an ash discharge port, and an ash discharge valve 13 is installed, and a flue gas inlet guide plate 10 is arranged above the flue gas inlet in the pre-dust collector.

[0032] The inner diameter of the middle section of the desulfurization tower is 4 meters. The upper part of the middle section of the desulfurization tower, namely the pre-dust removal section, is the Venturi tube bundle section 2, and 7 Venturi tubes are closely arranged vertically inside.

[0033]The upper section of the desulfurization t...

Embodiment 2

[0036] The flue gas volume of a sintering plant is 2000m 3 / h, sulfur dioxide content 700mg / Nm 3 , flue gas temperature 120 ℃. The flue gas desulfurization process of the present invention is used for desulfurization treatment, and the flue gas temperature at the outlet of the secondary dust collector is ≥70°C.

[0037] The relevant operating parameters of this embodiment are as follows:

[0038] Desulfurization agent consumption 2.5kg / h

[0039] Digested water consumption 2.2kg / h

[0040] Humidification water consumption 60kg / h

[0041] Supplementary water consumption 2kg / h

[0042] Ca / S(mol / mol)=1.2

[0043] Circular ash return 4.5kg / h

[0044] After treatment, the sulfur dioxide content is 56mg / Nm 3 , the desulfurization rate is 92%.

[0045] The specific process engineering is as follows.

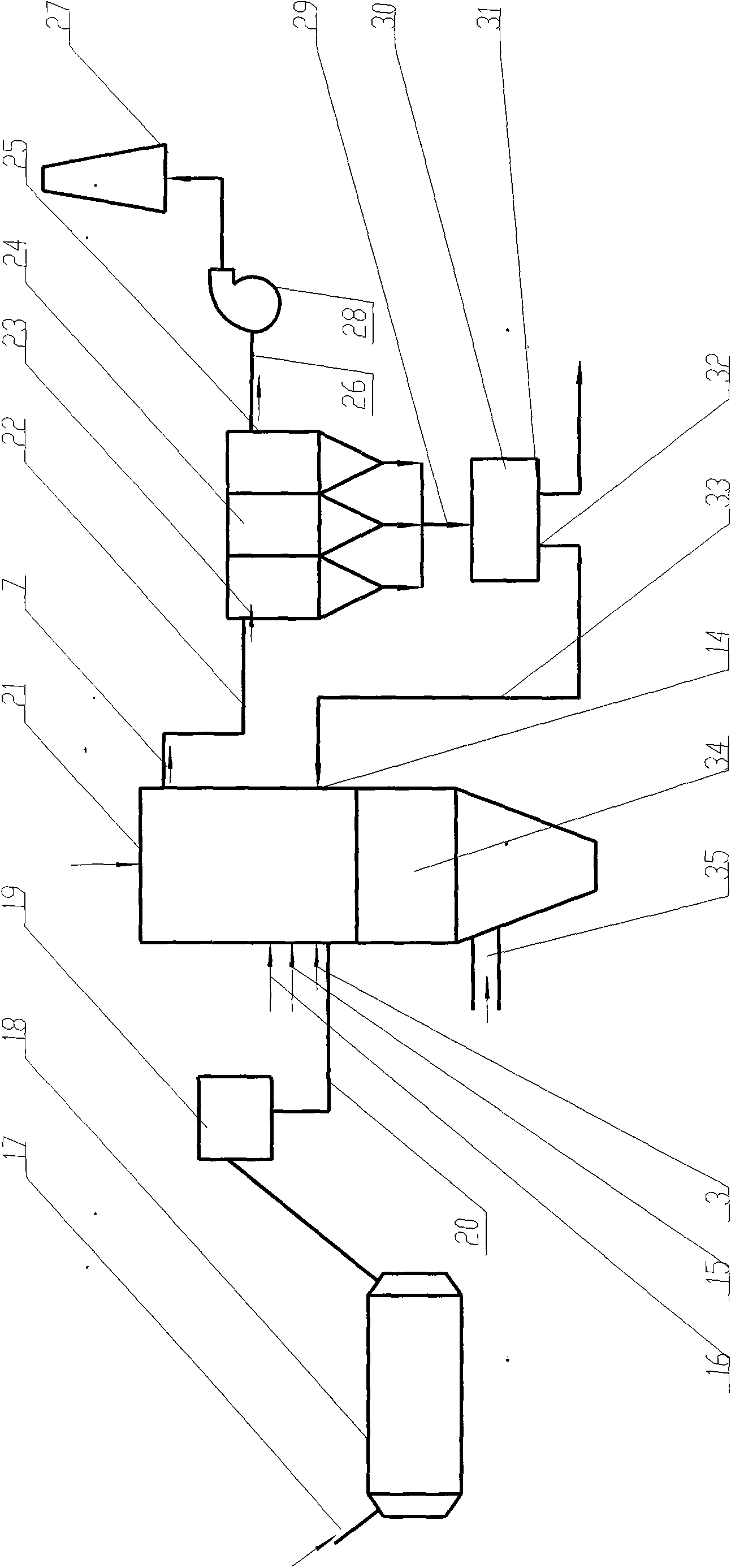

[0046] The blocky quicklime is sent into the mill 18 through the block lime inlet 17, and the quicklime powder is ground by the mill 18, and the lime powder with a particle si...

Embodiment 3

[0052] The flue gas volume of a sintering plant is 10000m 3 / h, sulfur dioxide content 800mg / Nm 3 , flue gas temperature 120 ℃. The flue gas desulfurization process of the present invention is used for desulfurization treatment, and the flue gas temperature at the outlet of the secondary dust collector is ≥70°C.

[0053] The relevant operating parameters of this embodiment are as follows:

[0054] Desulfurization agent consumption 12kg / h

[0055] Digested water consumption 11kg / h

[0056] Humidification water consumption 320kg / h

[0057] Supplementary water consumption 10kg / h

[0058] Ca / S(mol / mol)=1.3

[0059] Circular ash return 25kg / h

[0060] After treatment, the sulfur dioxide content is 40mg / Nm 3 , the desulfurization rate is 95%.

[0061] The specific process is as follows.

[0062] Grind the massive quicklime with a particle size of 80mm into quicklime powder by a mill, and grind the blocky quicklime into quicklime powder by a mill. After classification, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com