Composite impact material surface strengthening method and device

A technology of surface strengthening and sheet metal, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of difficult to handle, difficult to accurately control, and unreasonable overlapping joints, so as to expand the residual compressive stress area and prevent residual compressive stress. Tensile stress, improve the effect of stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

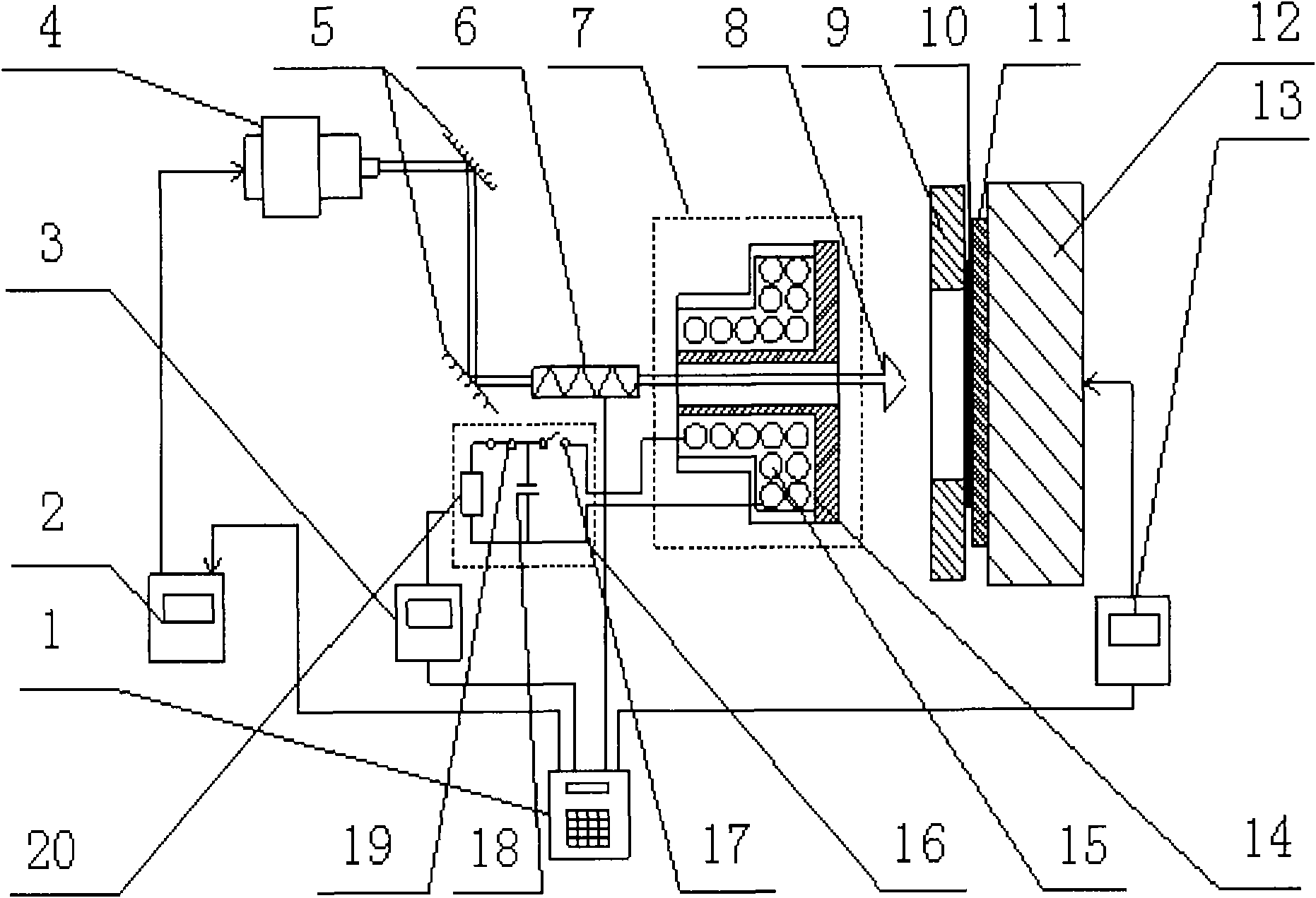

Embodiment 1

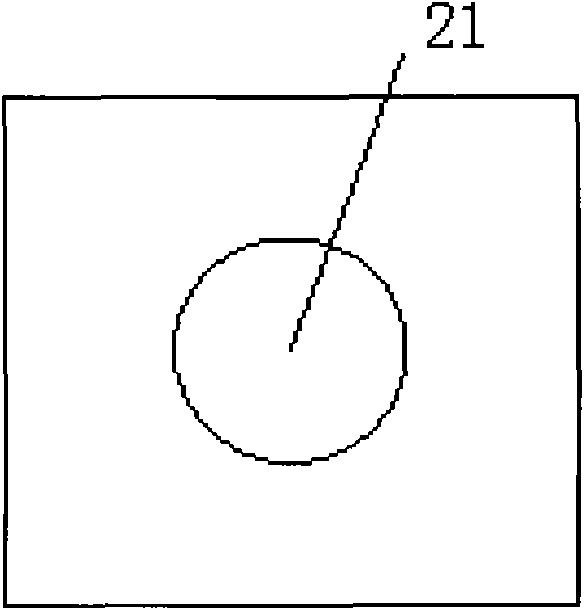

[0031] image 3 The sample sheet 11 in the sample is a 2024 aluminum alloy sheet with a size of 40×40mm and a thickness of 0.5mm. The sample sheet 11 is installed on the fixture 9, and the spot diameter is adjusted to 8mm by the spot adjustment device 6, and the laser energy is 25J impacts on it, and the circle in the middle is the impact area 21 of the sheet metal circular spot. The residual stress distribution during impact is as follows Figure 4 shown, from Figure 4 It can be seen that after the sample sheet 11 is impacted by laser, the residual pressure distribution in the impact area is not uniform, and the maximum pressure is not in the central area. The residual compressive stress tends to increase from the central area to 2mm, and the residual compressive stress from It gradually decreases, and tensile stress is produced outside the impact area of 6-8mm from the center, which shows that there are defects in laser shot peening.

[0032] Using the present inventio...

Embodiment 2

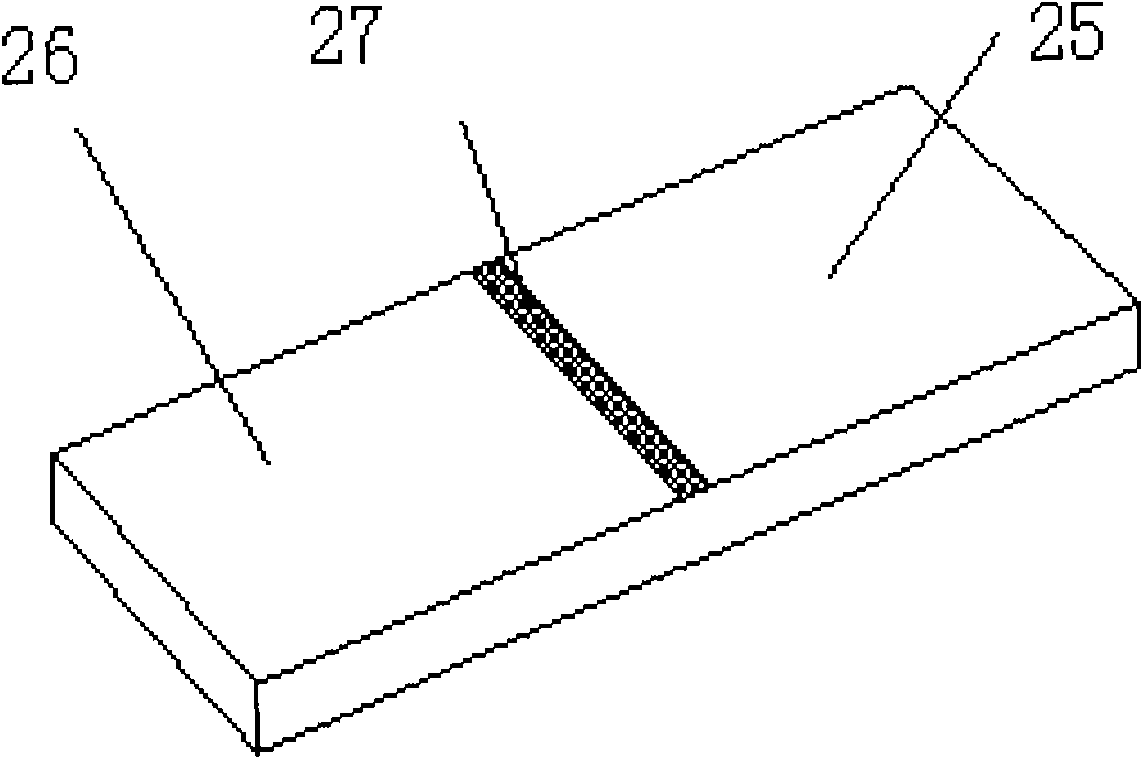

[0034] Image 6 Shown is a double-connected "dog-bone" fastening hole fatigue test piece, the diameter of the two central holes 22 in the spot impact area of the sample is 2mm, and an absorbing layer (aluminum foil 0.15mm) and a restraining layer are respectively coated on the impact strengthening area. layer (4.5mm thick K9 optical glass), in which one central hole 23 is used for separate laser shot peening strengthening, while the other central hole 24 is used for combined laser and electromagnetic pulse impact strengthening. Compared with the central hole 23 and 24 experiments, the sample was implemented After the two different methods described in Example 1, the results can be obtained by checking the hardness of the impact zone and by fatigue experiments. The results show that the hardness of the impact area on the surface of the specimen treated by laser alone is about 40% higher than that of the untreated specimen, and the fatigue life is increased by 2 to 10 times. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com