Method for preparing nitrogen doped nanometer titanium dioxide visible light photocatalyst

A nano-titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high drying temperature, reduced catalytic activity, easy collapse of pores, etc., and increase the diameter of pores. , The effect of increasing the specific surface area and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Configure 0.01mol / L titanium sulfate solution, add surfactant triethanolamine under stirring condition, the quality of surfactant accounts for 0.1% of the quality of titanium sulfate solution, add 1mol / L ammonia water after stirring evenly, make sulfuric acid Titanium is completely precipitated, continue to stir for 0.5h, and let stand and age for 20h;

[0023] 2) washing the precipitate in step 2) with deionized water until the total concentration of anions in the washed water is lower than 0.1mol / L, and then vacuum-drying the precipitate in an environment with a pressure below 1000Pa and a temperature below -10°C;

[0024] 3) After the precipitate is completely dried, it is heated to 450° C. and calcined for 1.5 h to obtain a nitrogen-doped nano-titanium dioxide photocatalyst. The color of the sample is light yellow, and it is recorded as 1# sample.

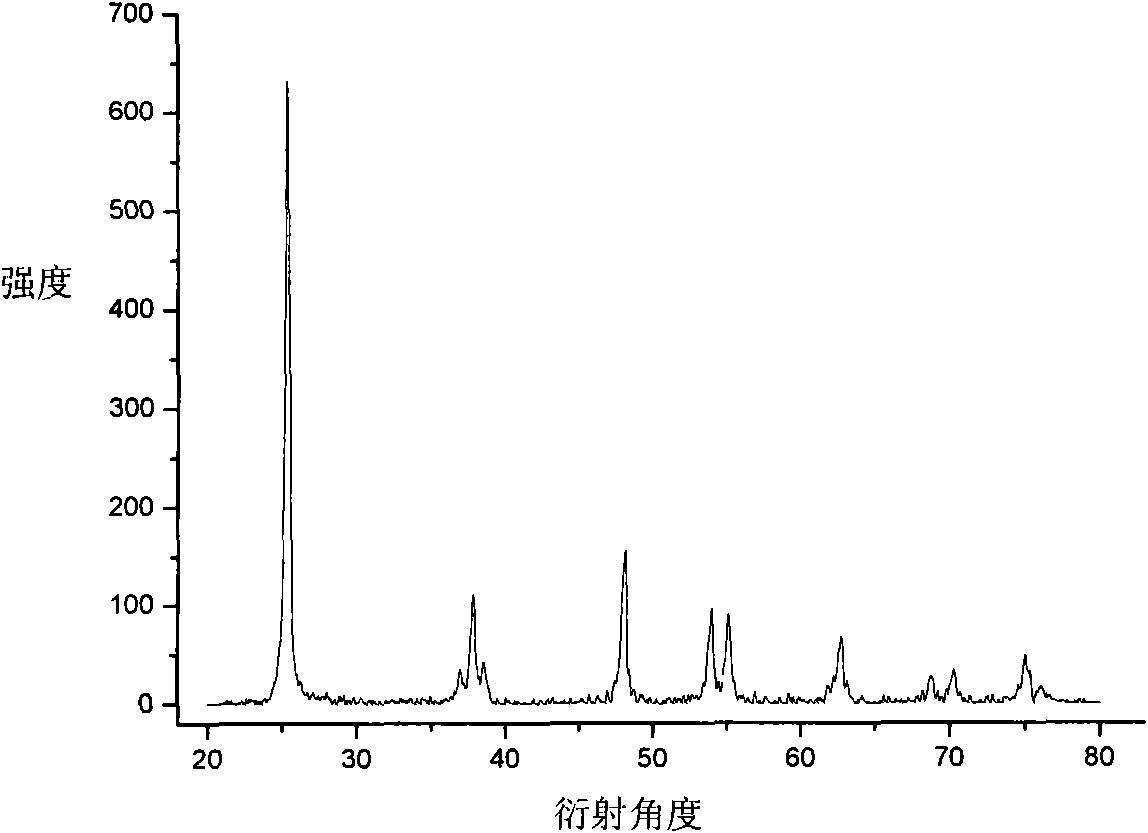

[0025] The structure of the 1# sample was detected by XRD. The sample was anatase nitrogen-doped nano-titanium dio...

Embodiment 2

[0027] 1) Configure 1mol / L titanium sulfate solution, add surfactant Tween under the condition of stirring, the mass of Tween added is 0.2% of the mass of titanium sulfate solution, after stirring evenly, add 5mol / L ammonia water to completely precipitate titanium sulfate , continue to stir for 2h, and leave to age for 10h;

[0028] 2) Wash the precipitate with deionized water until the total concentration of all anions in the washed water is lower than 0.1mol / L, and then vacuum-dry the precipitate in an environment with a pressure below 800Pa and a temperature below -5°C;

[0029] 3) After the precipitate is completely dried, it is heated to 800° C. and calcined for 0.5 h to obtain a nitrogen-doped titanium dioxide photocatalyst. The color of the sample is single yellow, which is recorded as 2# sample.

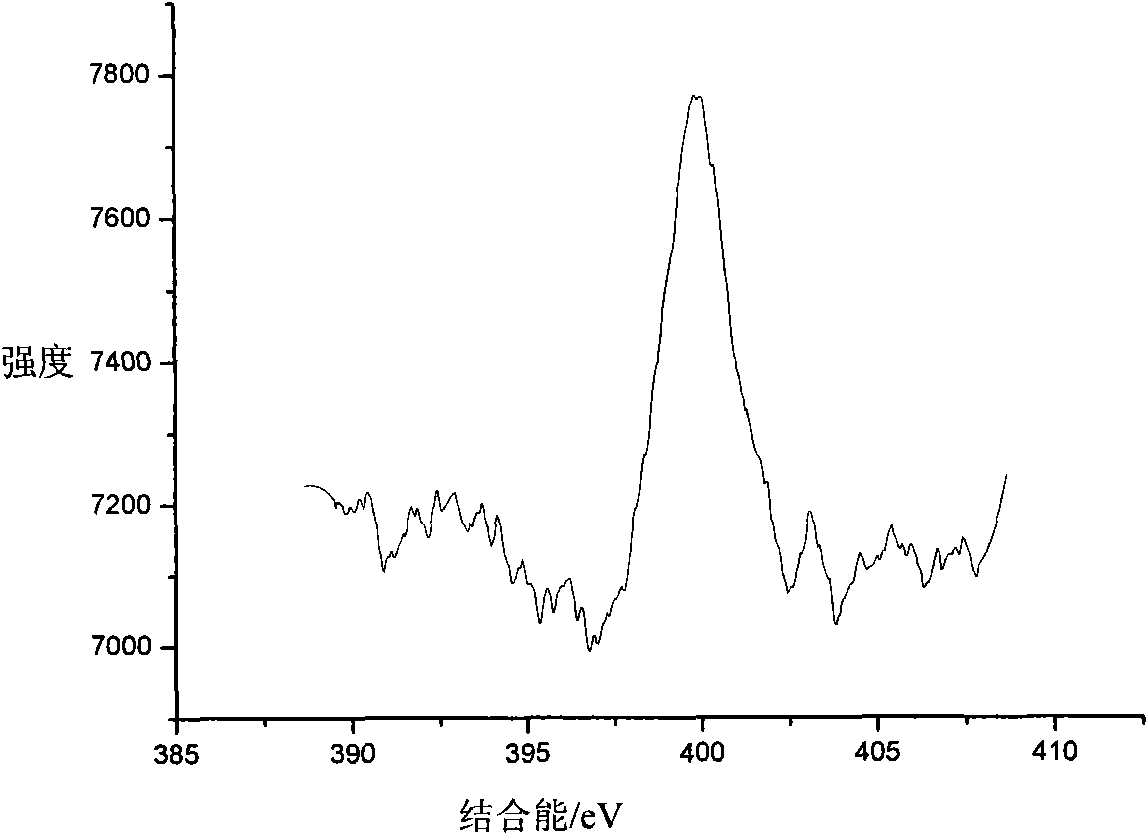

[0030] The structure of the 2# sample was detected by XPS, and the results showed that N doping entered TiO 2 within the lattice.

Embodiment 3

[0032] 1) Configure 10mol / L titanium tetrachloride solution, add surfactant polyethylene glycol under the condition of stirring, the quality of surfactant accounts for 0.3% of the total mass of titanium tetrachloride solution, add 2mol / L after stirring evenly ammonium bicarbonate aqueous solution to completely precipitate titanium tetrachloride, continue to stir for 2 hours, and leave to age for 24 hours;

[0033] 2) washing the precipitate with deionized water until the total concentration of all anions in the washed water is lower than 0.1mol / L, and then vacuum-drying the precipitate in an environment with a pressure below 200Pa and a temperature below -30°C;

[0034] 3) After the precipitate is completely dried, it is heated to 500° C. and calcined for 1 hour to obtain a nitrogen-doped titanium dioxide photocatalyst. The color of the sample is bright yellow, which is recorded as 3# sample.

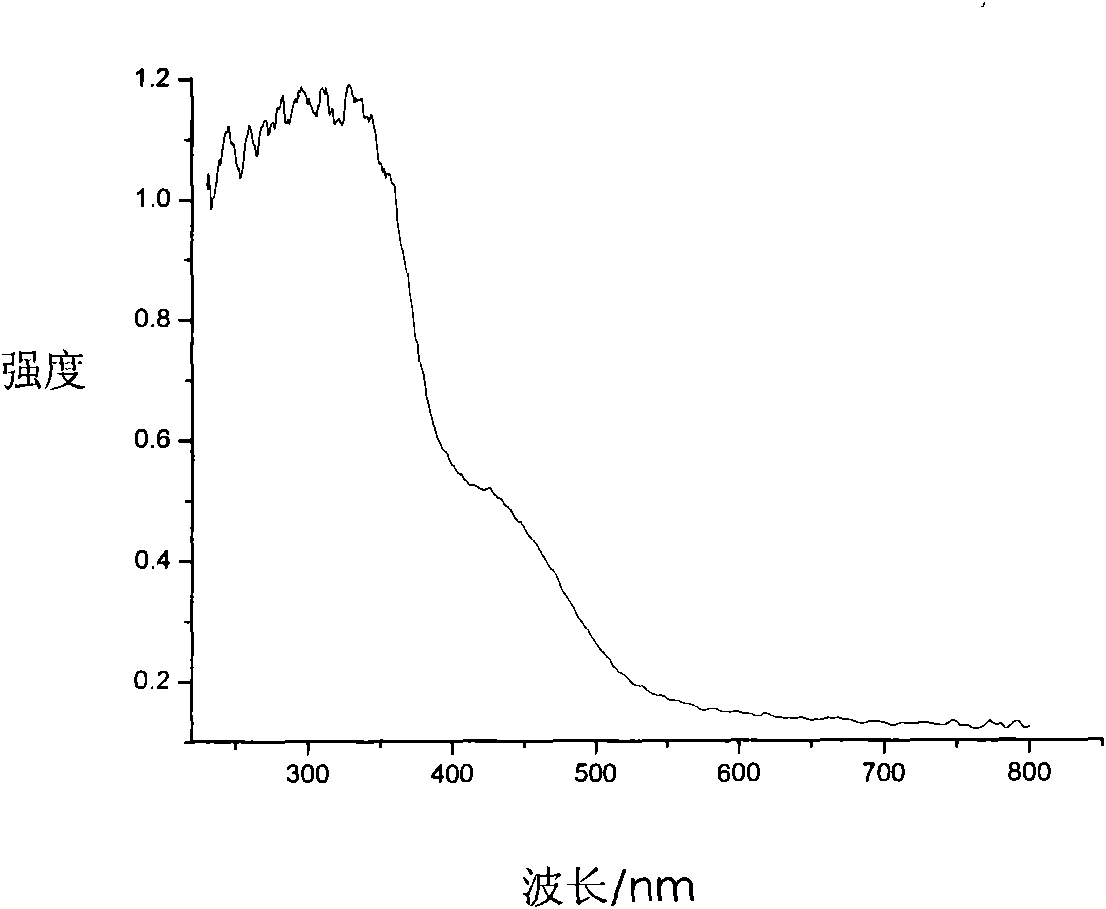

[0035] The spectral performance of the 3# sample is tested by ultraviolet-visible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com