Impregnant for preparing copper clad plates

A technology of impregnating materials and copper-clad laminates, which is applied in the field of impregnating materials for spherical barium sulfate, can solve problems such as inappropriateness, and achieve the effects of reducing dosage, reducing wear and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

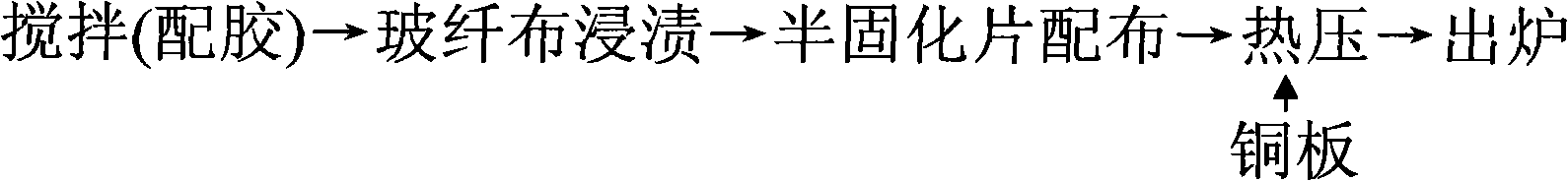

Method used

Image

Examples

Embodiment Construction

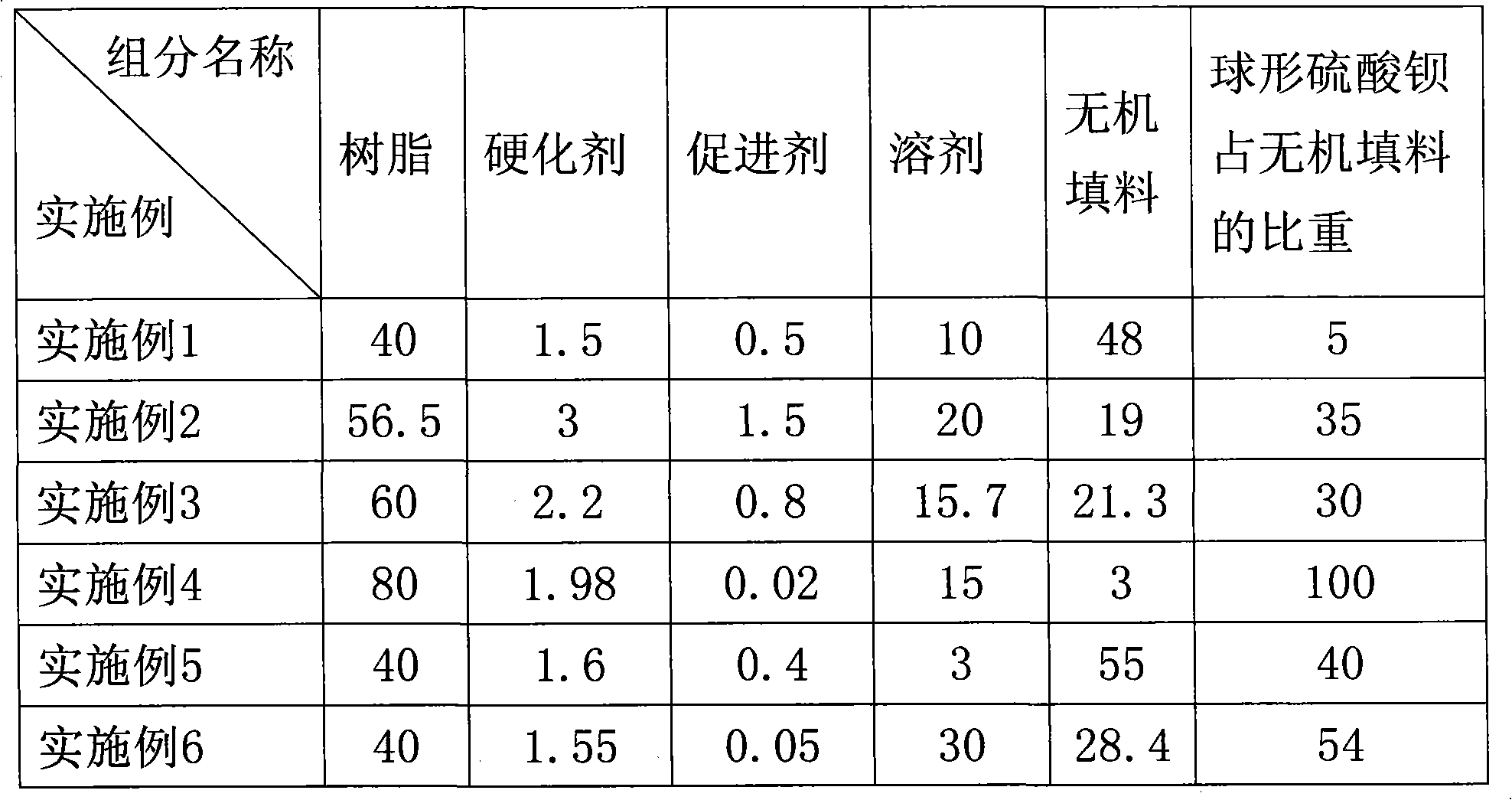

[0024] The formula of the embodiment of the invention is referring to Table 1:

[0025] Table 1: (unit: weight percentage)

[0026]

[0027] The spherical barium sulfate has a molecular formula whose main body is BaSO 4 Powder material (prepared by sulfuric acid method).

[0028] The resin is at least one of epoxy resin, phenolic resin and cyanophosphoester.

[0029] The hardener is at least one of melamine and diamine-based.

[0030] The accelerator is at least one of imidazoles and aromatic diamines.

[0031] The solvent is at least one of dimethylformamide, butanone, methanol, acetic acid and ethylene glycol.

[0032] The inorganic filler also contains at least one of aluminum hydroxide, magnesium hydroxide, silicon dioxide, kaolin and talc.

[0033] Spherical barium sulfate used in the present invention is prepared by the sulfuric acid method, and the product obtained after processing is a colorless orthorhombic crystal, forming a core-shell structure with a comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap